Tensile fire resistant cable

A fire-resistant cable and tensile technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of weak tensile strength and no fire, and achieve the effect of increasing the draw-to-weight ratio, reducing the height of the tower, and improving the sag performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose, the specific embodiments, structural features and effects of the present invention will be described in detail below with reference to the accompanying drawings and examples.

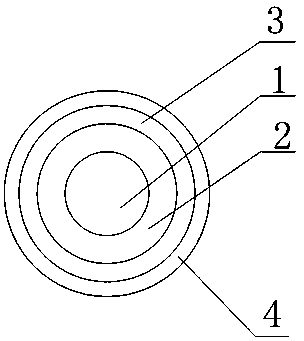

[0026] Such as figure 1 The tensile and fire-resistant cable shown includes an inner conductor 1, a shielding layer 2 coated by the conductor 1, and an insulating layer 3 coated by the shielding layer 2. The material of the insulating layer 3 is modified cross-linked ethylene-tetrafluoroethylene Copolymer material, the thinnest thickness of the insulating layer 3 is not less than 0.105mm. The conductor 1 is formed by twisting carbon fiber monofilaments and graphene nanomaterial nanotube monofilaments; the monofilaments are twisted into a two-layer structure or a multilayer structure. The central axis of the monofilament of the same layer forms a circle, which is conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com