Two-step all-component recycling method of waste circuit boards

A technology for waste circuit boards and components, applied in plastic recycling, electronic waste recycling, recycling technology and other directions, can solve the problem of not being able to achieve full component recovery of waste circuit boards, and achieve the recyclability of solvents and catalysts. Strong operability, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1, waste and old circuit board is cut to 1cm, adds dichloromethane (the mass ratio of waste and old circuit board and methylene chloride is 1:20) the epoxy resin-glass fiber composite material in the circuit board substrate is swelled, at 0 Swelling at ℃ for 72 hours makes the epoxy resin-glass fiber composite material swell and fluffy, and at the same time, makes the interface between the epoxy resin-glass fiber composite material and the copper foil of the circuit board substrate partly separated.

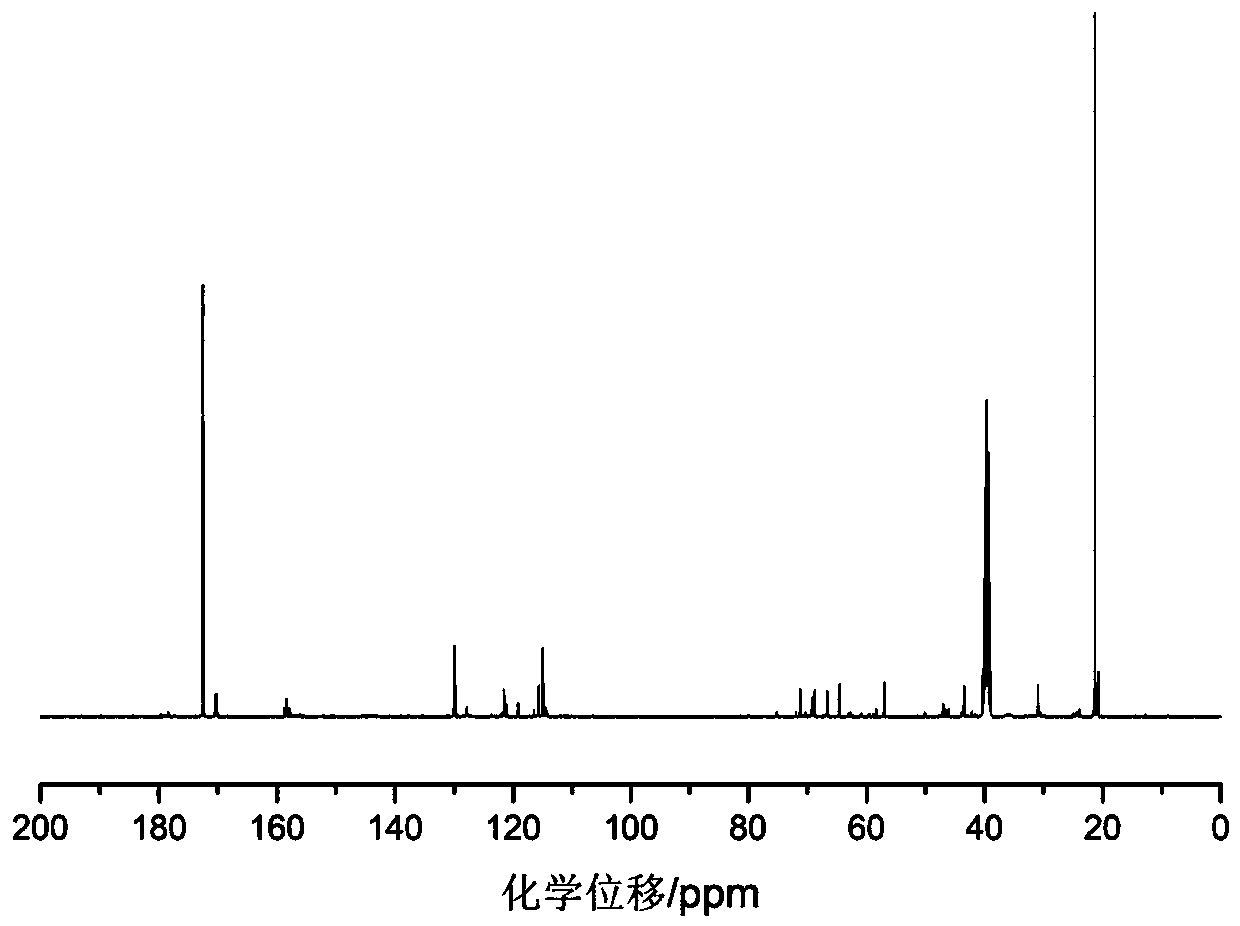

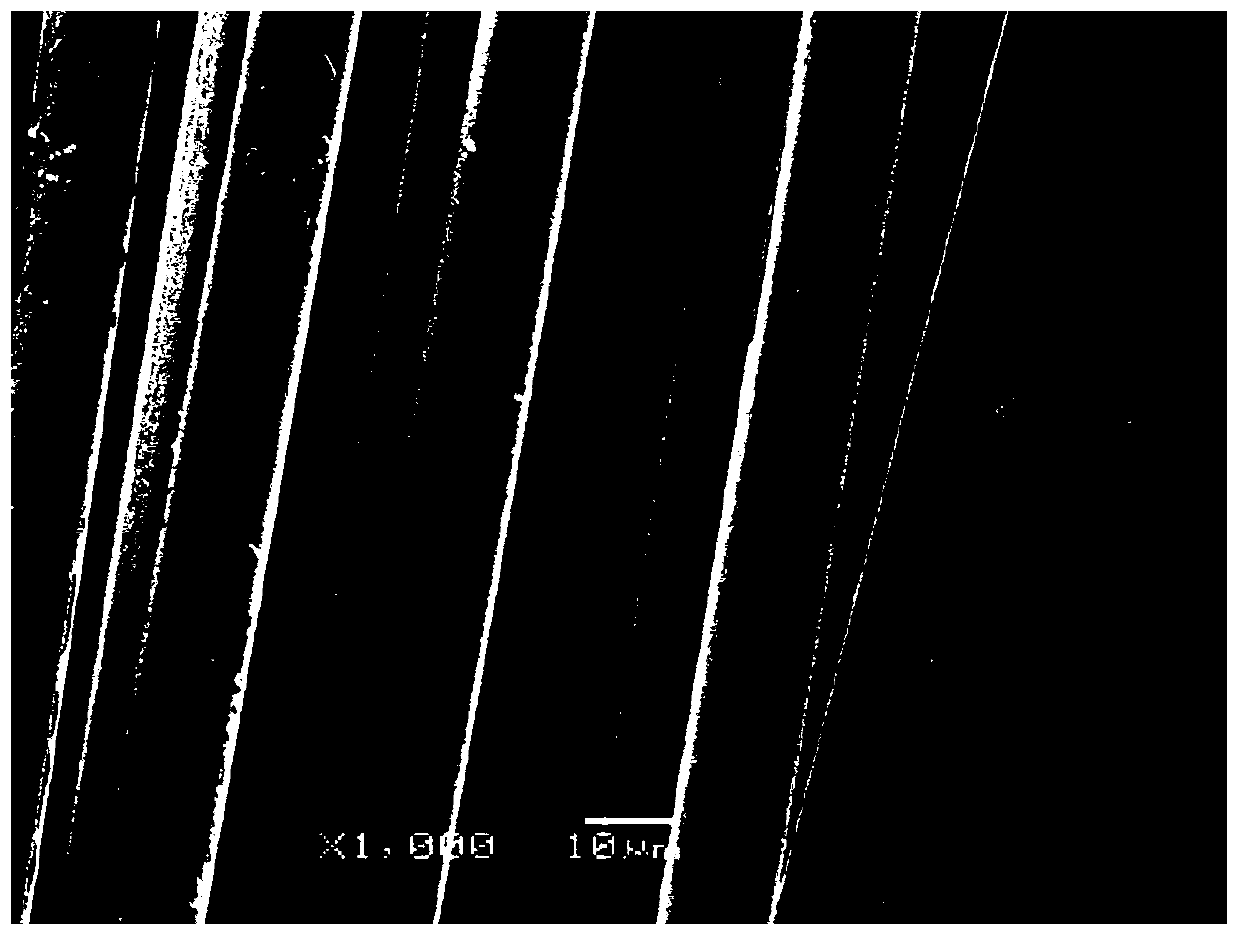

[0027] Step 2, immerse the swollen circuit board substrate in AlCl with a catalyst mass fraction of 10% 3 -Acetic acid system, degraded at 180°C for 8h, degraded the epoxy resin-glass fiber composite material, degraded the epoxy resin into soluble oligomers, and dissolved the epoxy resin oligomers by acetone (epoxy resin oligomers The mass ratio to acetone is 1:50), which can recycle glass fiber, polybrominated biphenyls, copper foil and other metal components in wast...

Embodiment 2

[0029] Step 1, cut the waste circuit board to 0.5m, add chloroform (the mass ratio of waste circuit board and chloroform is 1:1) to swell the epoxy resin-glass fiber composite material in the circuit board substrate, and swell at 50°C After 48 hours, the epoxy resin-glass fiber composite material is swollen and fluffy, and at the same time, the interface between the epoxy resin-glass fiber composite material and the copper foil of the circuit board substrate is partially separated.

[0030] Step 2, immerse the swollen circuit board substrate in FeCl with a mass fraction of catalyst of 20% 3 -Formic acid system, degraded at 200°C for 12h, degraded the epoxy resin-glass fiber composite material, degraded the epoxy resin into soluble oligomers, and dissolved the epoxy resin oligomers by tetrahydrofuran (epoxy resin oligomers The mass ratio to THF is 1:80), which can recycle glass fiber, polybrominated biphenyls, copper foil and other metal components in waste circuit boards.

Embodiment 3

[0032]Step 1, cut the waste circuit board to 1m, add toluene (the mass ratio of waste circuit board and toluene is 1:60) to swell the epoxy resin-glass fiber composite material in the circuit board substrate, and swell at 100°C for 36h , so that the epoxy resin-glass fiber composite material is swollen and fluffy, and at the same time, the interface between the epoxy resin-glass fiber composite material and the copper foil of the circuit board substrate is partially separated.

[0033] Step 2, immerse the swollen circuit board substrate in a toluenesulfonic acid-acetic acid system with a catalyst mass fraction of 1%, and degrade it at 250°C for 30 minutes to degrade the epoxy resin-glass fiber composite material, and the epoxy resin is degraded into a low-soluble Polymers, dissolving epoxy resin oligomers by N,N-dimethylformamide (the mass ratio of epoxy resin oligomers and N,N-dimethylformamide is 1:100), which can recycle waste Glass fiber, polybrominated biphenyls, copper f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com