Preparation process of anti-cracking concrete

A preparation process and concrete technology, which is applied in the field of concrete, can solve the problems such as batching, paving, forming, cutting and other processes that are difficult to achieve organic integration, so as to increase the loss of concrete slump, easy to obtain raw materials, and convenient construction and use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

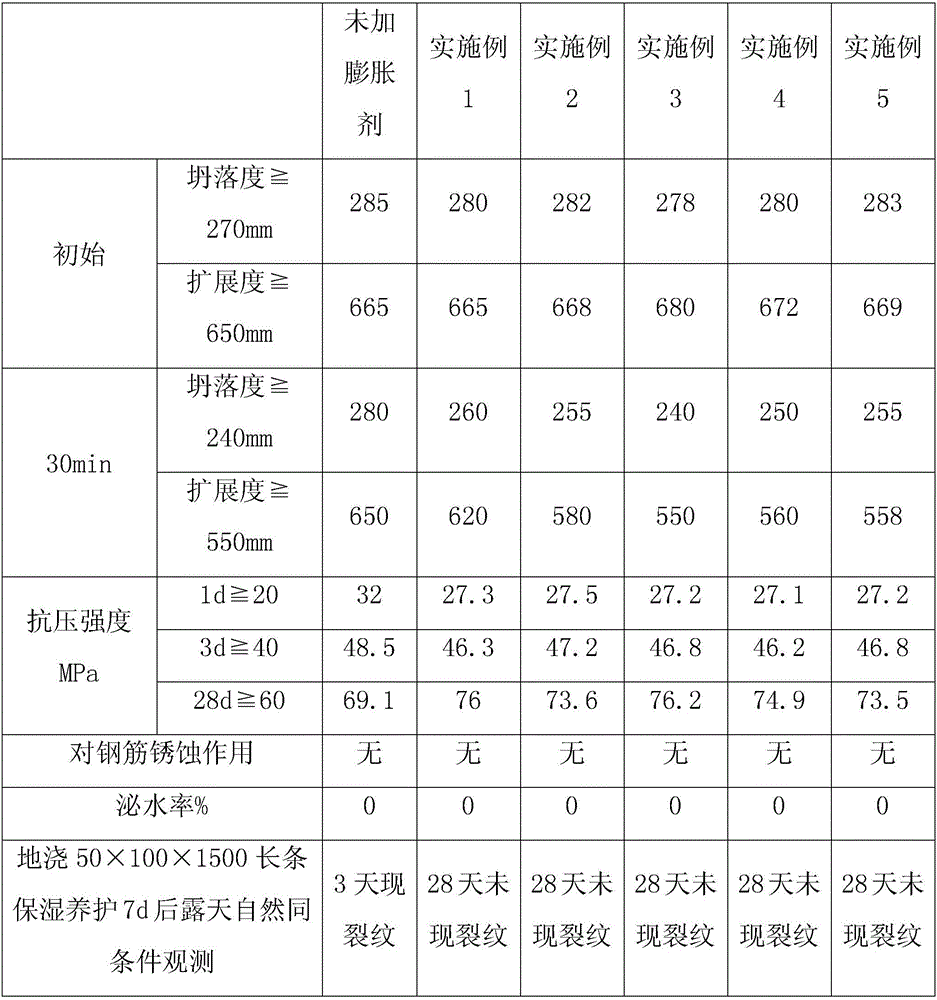

Examples

Embodiment 1

[0025] A preparation process for crack-resistant concrete, comprising the following steps:

[0026] (1) Concrete ratio design, its mass composition is as follows: 100 parts of cement, 80 parts of fine aggregate stones, 100 parts of coarse aggregate stones, 10 parts of rubber particles, 50 parts of fly ash, 12 parts of micro silica fume, 10 parts of amide epichlorohydrin resin, 8 parts of expansion agent, 200 parts of water;

[0027] (2) The mixture is stirred evenly, and the stirring temperature is 15-18°C,

[0028] (3) Concrete pouring: Concrete and high-strength imitation steel fiber mesh are alternately poured into the formwork, and the concrete is troweled in the process; the diameter of the fiber in the high-strength imitation steel fiber mesh is 0.6mm;

[0029] (4) Concrete cutting and polishing: use water grinding method to polish, and add polishing medium.

[0030] Wherein, the composition of mass parts of expansion agent is as follows: 4 parts of iron vitrified mud,...

Embodiment 2

[0036] A preparation process for crack-resistant concrete, comprising the following steps:

[0037] (1) Concrete ratio design, its mass composition is as follows: 120 parts of cement, 100 parts of fine aggregate stones, 120 parts of coarse aggregate stones, 20 parts of rubber particles, 55 parts of fly ash, 15 parts of micro silica fume, poly 12 parts of amide epichlorohydrin resin, 9 parts of expansion agent, 210 parts of water;

[0038] (2) The mixture is stirred evenly, and the stirring temperature is 18-20°C,

[0039] (3) Concrete pouring: Concrete and high-strength imitation steel fiber mesh are alternately poured into the formwork, and the concrete is troweled in the process; the diameter of the fiber in the high-strength imitation steel fiber mesh is 0.8mm;

[0040] (4) Concrete cutting and polishing: use water grinding method to polish, and add polishing medium.

[0041] Among them, the mass parts of the expansion agent are composed as follows: 4.2 parts of ferric vi...

Embodiment 3

[0047] A preparation process for crack-resistant concrete, comprising the following steps:

[0048] (1) Concrete ratio design, its mass composition is as follows: 160 parts of cement, 100 parts of fine aggregate stones, 160 parts of coarse aggregate stones, 40 parts of rubber particles, 65 parts of fly ash, 16 parts of micro silica fume, poly 12 parts of amide epichlorohydrin resin, 10 parts of expansion agent, 250 parts of water;

[0049] (2) The mixture is stirred evenly, and the stirring temperature is 20-25° C.,

[0050] (3) Concrete pouring: Concrete and high-strength imitation steel fiber mesh are alternately poured into the formwork, and the concrete is troweled in the process; the diameter of the fiber in the high-strength imitation steel fiber mesh is 1.2mm;

[0051] (4) Concrete cutting and polishing: use water grinding method to polish, and add polishing medium.

[0052] Wherein, the composition of mass parts of expansion agent is as follows: 4 parts of ferric vit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com