A production process of copper-aluminum composite decorative material

A decorative material, copper-aluminum composite technology, applied in manufacturing tools, rolling mill control devices, metal processing equipment, etc., can solve the problems of complicated process, difficult preparation of wide-width and high-strength copper-aluminum composite materials, and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

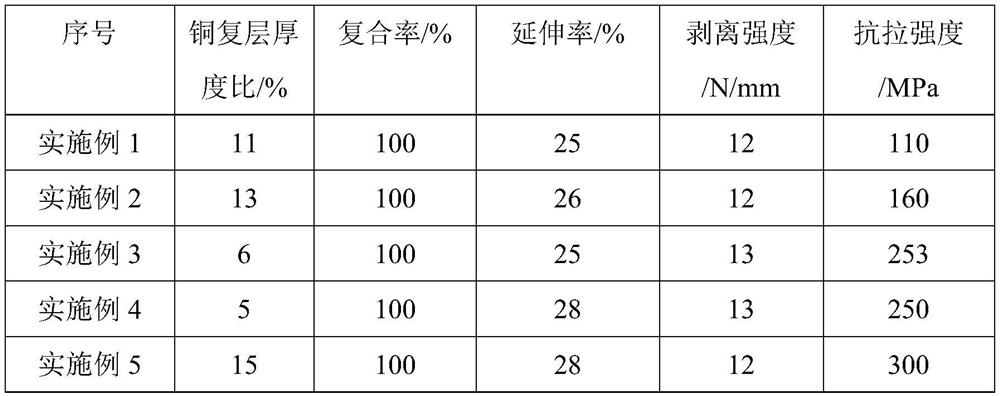

Examples

Embodiment 1

[0023] The production method of the copper-aluminum composite decorative material of the present embodiment comprises the following steps:

[0024] (1) One side surface of the T2 copper plate with a width of 1200mm and a thickness of 1.0mm is electroplated with tin to obtain a copper plate blank with a tin-plated layer, and the thickness of the tin-plated layer is 0.003mm; Tin sulfamate, 0.8% sulfuric acid, 0.9% AlCl 3 and 6% trisodium phosphate, the solvent is water; the temperature of electroplating tin is 200°C, the voltage is 380V, the current is 600A, and the current density is 0.5A / dm 2 ;

[0025] (2) Facing the aluminum plate with the tin-plated layer of the copper plate blank with the tin-plated layer, it is hot-rolled and compounded with 1060 aluminum plates with a thickness of 8 mm, annealed and heat-treated, and cold-rolled to obtain a copper-aluminum composite decorative material; the temperature of the hot-rolled compound is 300° C. The rolling speed of hot-roll...

Embodiment 2

[0027] The production method of the copper-aluminum composite decorative material of the present embodiment comprises the following steps:

[0028] (1) One side surface of the T2 copper plate with a width of 1500mm and a thickness of 1.2mm is electroplated with tin to obtain a copper plate blank with a tin-plated layer, and the thickness of the tin-plated layer is 0.010mm; Tin sulfamate, 2% sulfuric acid, 1.1% AlCl 3 and 6.5% trisodium phosphate, the solvent is water; the temperature of tin plating is 280°C, the voltage is 380V, the current is 800A, and the current density is 3.0A / dm 2 ;

[0029] (2) Facing the aluminum plate with the tin-plated layer of the copper plate blank with the tin-plated layer, hot-rolling and compounding with 8mm thick 3004 aluminum plate, annealing heat treatment, cold-rolling, to obtain the copper-aluminum composite decorative material; the temperature of hot-rolling and compounding is 350 DEG C, The rolling speed of hot-rolling cladding is 6m / mi...

Embodiment 3

[0031] The production method of the copper-aluminum composite decorative material of the present embodiment comprises the following steps:

[0032] (1) The both sides surfaces of T2 copper plate of 1800mm wide 1.0mm thickness are electroplated tin, obtain the copper plate blank with two-layer tin-plated layer, the thickness of each layer of tin-plated layer is 0.020mm; Fraction 3% tin sulfamate, 3% sulfuric acid, 2% AlCl 3 and 4% trisodium phosphate, the solvent is water; the temperature of electroplating tin is 320°C, the voltage is 380V, the current is 700A, and the current density is 4.5A / dm 2 ;

[0033] (2) With the tin-plated layer of the copper plate blank with the tin-plated layer facing the aluminum plate, hot rolling and compounding with two 8mm thick 4343 aluminum plates, annealing heat treatment, cold rolling, obtain copper-aluminum composite decorative material; the temperature of hot-rolling compounding is 350 ℃, the rolling speed of hot rolling composite is 6m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com