PTFE substrate material for high-frequency copper-clad plate and preparation method of PTFE substrate material

A technology of PTFE and copper clad laminates, which is applied in the field of material science and engineering, can solve the problems of high water absorption, neglect of the importance of thermal expansion coefficient, high dielectric loss, etc., and achieve low water absorption, good industrialization foundation and application prospects, low dielectric The effect of electrical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail with reference to the following examples, but these examples are not intended to limit the scope of the present invention.

[0028] In the present invention, the method for preparing a substrate material for a high-frequency copper-clad laminate comprises the following steps:

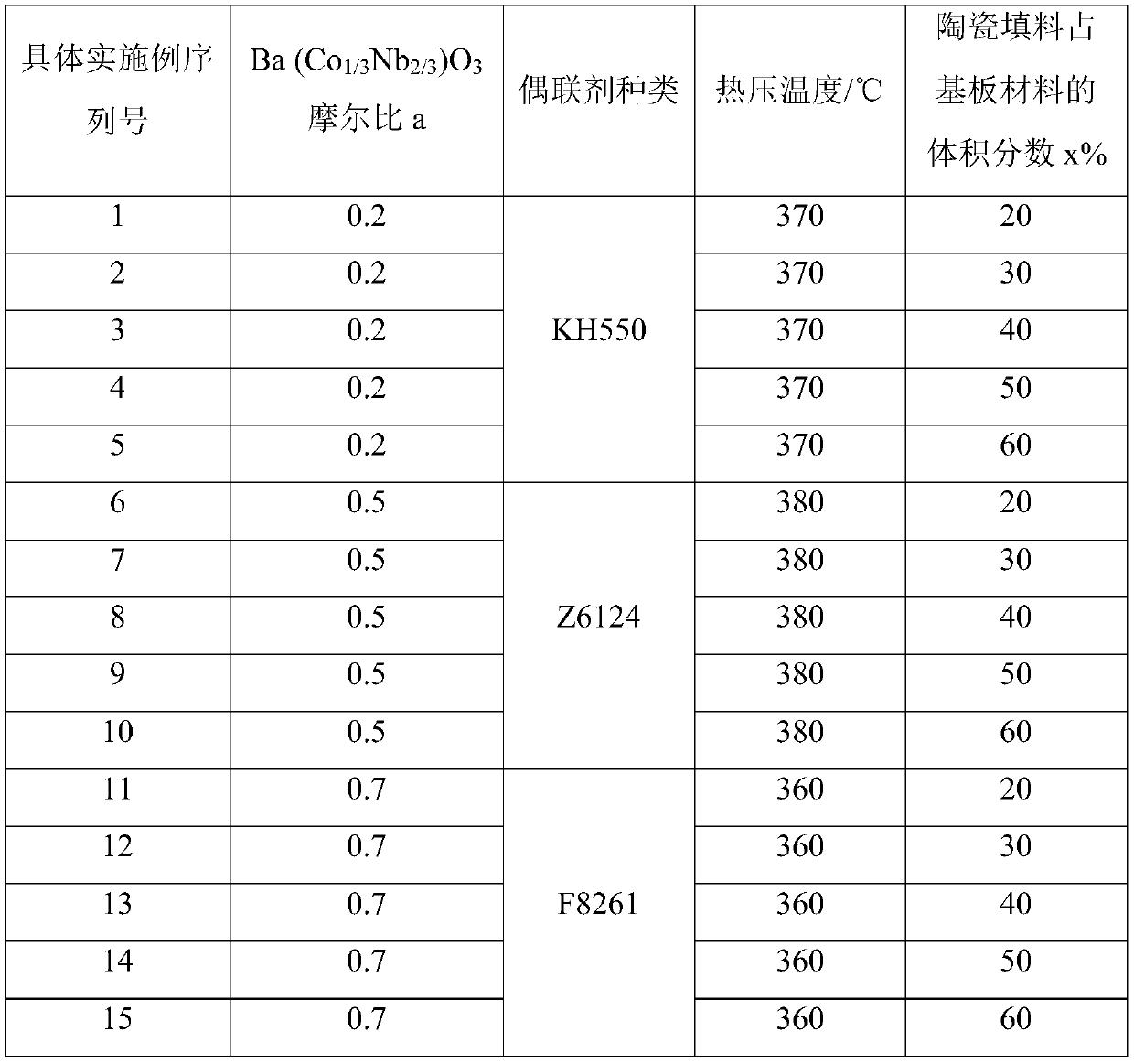

[0029] (1) According to the molar ratio of 3: a: (1-a): 2, take the powdered raw material BaCO 3 , CoO, ZnO and Nb 2 o 5 , wherein 0.2≤a≤0.7; ball milled for 24 hours and then sintered at 1200°C for 4 hours; further ground to a particle size of 0.2-1 μm to obtain a ceramic filler;

[0030] (2) According to the mass ratio of 50:1, take ceramic filler and coupling agent; disperse ceramic filler in ethanol, control the mass ratio of ethanol and ceramic filler to 6:1; add coupling agent, stir at 60°C for 4h, After drying at 120°C, the ceramic filler modified by the coupling agent is obtained; the coupling agent is any one of the following: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com