Negative pole sheet for lithium ion battery and preparation method of negative electrode sheet

A technology of lithium ion battery and negative pole piece is applied in the field of lithium ion battery, which can solve the problems that the charging and discharging efficiency cannot reach the practical level, cannot achieve the effect of supplementing lithium, and limit the popularization and application, so as to improve the first efficiency and energy density. , Improve the cycle retention rate, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

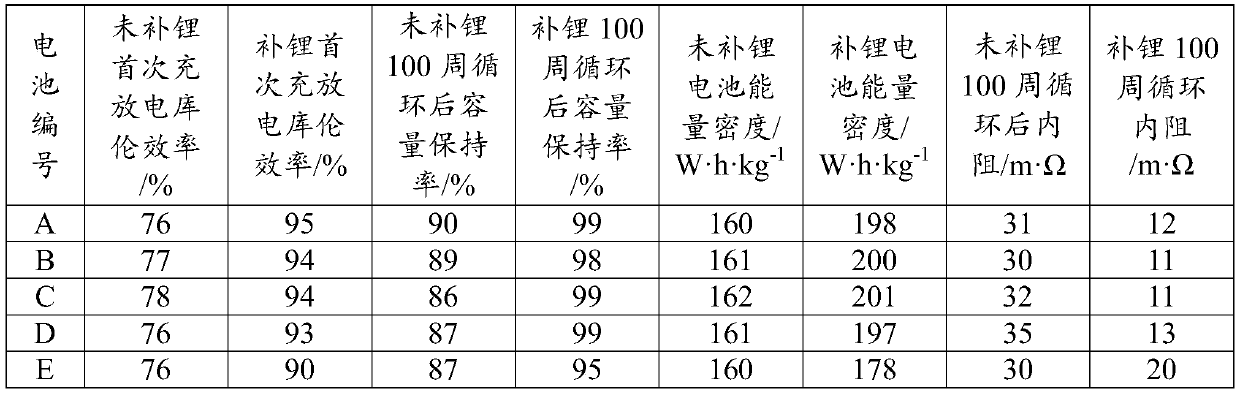

Embodiment 1

[0040] This embodiment provides a lithium-ion battery negative electrode composite lithium-replenishing pole piece, which is prepared by the following steps:

[0041] (1) Add 1 mg of graphene flakes to 30 ml of cyclohexane solution under a nitrogen atmosphere, ultrasonically disperse for 2 hours, and stir magnetically at 40° C. for 12 hours to obtain a graphene dispersion;

[0042] (2) Then under a nitrogen atmosphere, 1 mL of butyllithium with a concentration of 1mol / L is added to the graphene dispersion in step (1), and mixed uniformly to obtain a spray coating;

[0043] (3) Electrospinning (voltage 20KV, spraying speed 0.02mm / s) is carried out by using a spinning head with a diameter of 1.0mm, and the spraying solution of step (2) is sprayed onto the copper foil and dried;

[0044] (4) Put the product of step (3) in a muffle furnace, and the temperature of the muffle furnace is raised to 700°C at a rate of 5°C / min. Using methane gas as a carbon source, carbon coating is car...

Embodiment 2

[0056] This embodiment provides a lithium-ion battery negative electrode composite lithium-replenishing pole piece, which is prepared by the following steps:

[0057] (1) Add 1 mg of graphene flakes to 30 ml of cyclohexane solution, ultrasonically disperse for 2 hours, and magnetically stir at 40°C for 24 hours to obtain a graphene dispersion;

[0058] (2) Then under a nitrogen atmosphere, 1 mL of tert-butyllithium with a concentration of 1mol / L is added to the graphene dispersion in step (1), and mixed uniformly to obtain a spray coating;

[0059] (3) Carry out electrospinning (voltage 20KV, spray speed 0.02mm / s) with the spinning head of diameter 0.6mm, step (2) spray liquid is sprayed on the copper foil, dry;

[0060] (4) Put the product of step (3) in a muffle furnace, and the temperature of the muffle furnace is raised to 700°C at a rate of 5°C / min. Using methane gas as a carbon source, carbon coating is carried out for 3 hours, and the obtained material is the The lithi...

Embodiment 3

[0063] This embodiment provides a lithium-ion battery negative electrode composite lithium-replenishing pole piece, which is prepared by the following steps:

[0064] (1) Add 1 mg of graphene flakes to 30 ml of cyclohexane solution, ultrasonically disperse for 2 hours, and magnetically stir at 40°C for 24 hours to obtain a graphene dispersion;

[0065] (2) Then, under a nitrogen atmosphere, 1mL of phenyllithium with a concentration of 1mol / L is added to the graphene dispersion in step (1), and mixed uniformly to obtain a spray coating;

[0066] (3) Electrospinning (voltage 20KV, spraying speed 0.02mm / s) is carried out by using a spinning head with a diameter of 1.6mm, and the spraying solution of step (2) is sprayed onto the copper foil and dried;

[0067] (4) Put the product of step (3) in a muffle furnace at 700°C, use methane gas as the carbon source, and carry out carbon coating for 3 hours, and the obtained material is the lithium-ion battery negative electrode composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com