Composite positive electrode material of aluminum-titanium double-doped lithium manganate and 523-type ternary material and preparation method of composite positive electrode material

A composite cathode material, lithium manganate technology, applied in the direction of positive electrodes, electrical components, battery electrodes, etc., can solve the problems of poor cycle performance, reduced speed, low safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

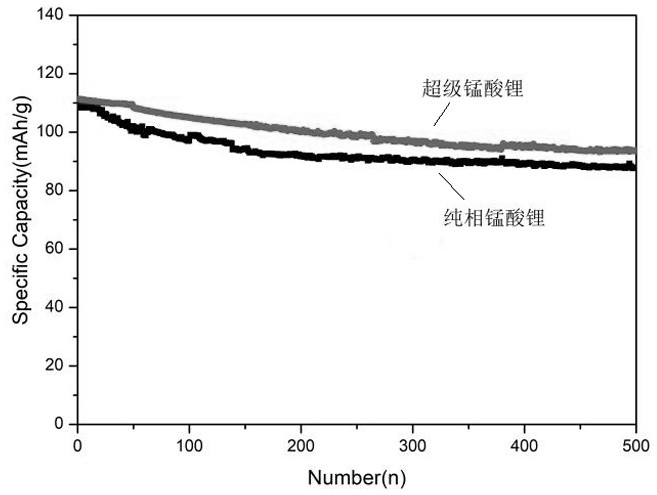

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

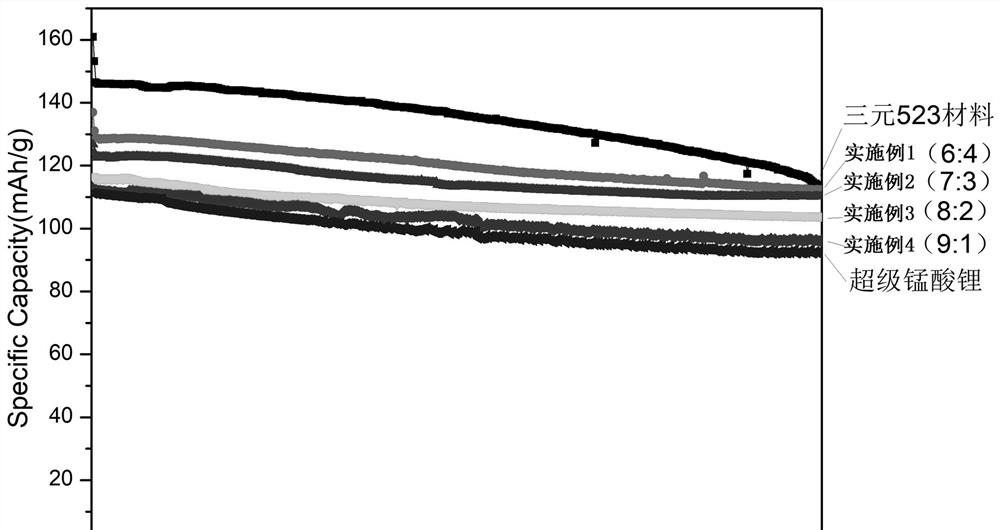

[0028] Preparation of composite material (mass ratio 6:4) of aluminum-titanium double-doped lithium manganate and 523-type ternary material

[0029] 1. Preparation of aluminum-titanium double-doped lithium manganese oxide material: electrolytic manganese dioxide (EMD) and lithium carbonate were weighed into a ball mill tank according to the stoichiometric ratio of 1.03, and then weighed according to the doping amount of aluminum and titanium of 4.0%. Aluminum salt and titanium salt were mixed by dry ball milling at a speed of 300 rad / min for 2 h. After sieving, they were sintered in an air atmosphere in a muffle furnace. The sintering procedure was: Raise the temperature to 830°C, keep it warm for 12 hours, then cool to room temperature with the furnace, and obtain aluminum-titanium double-doped lithium manganate after sieving.

[0030] 2. Preparation of 523-type ternary spherical material: Weigh an appropriate amount of lithium salt, 523 precursor, and zirconia ball milling b...

Embodiment 2

[0033] Preparation of composite material of aluminum-titanium double-doped lithium manganese oxide and 523-type ternary material (mass ratio 7:3)

[0034]1. Preparation of aluminum-titanium double-doped lithium manganese oxide material: electrolytic manganese dioxide (EMD) and lithium carbonate were weighed into a ball mill tank according to the stoichiometric ratio of 1.03, and then weighed according to the aluminum-titanium doping amount of 6.0%. Aluminum salt and titanium salt were mixed by dry ball milling at a speed of 300 rad / min for 2 h. After sieving, they were sintered in an air atmosphere in a muffle furnace. The sintering procedure was: Raise the temperature to 830°C, keep it warm for 12 hours, then cool to room temperature with the furnace, and obtain aluminum-titanium double-doped lithium manganate after sieving.

[0035] 2. Preparation of 523-type ternary spherical material: Weigh an appropriate amount of lithium salt, 523 precursor, and zirconia ball milling bea...

Embodiment 3

[0038] Preparation of composite material (mass ratio 8:2) of aluminum-titanium double-doped lithium manganese oxide and 523-type ternary material

[0039] 1. Preparation of aluminum-titanium double-doped lithium manganese oxide material: electrolytic manganese dioxide (EMD) and lithium carbonate were weighed into a ball mill jar according to the stoichiometric ratio of 1.05, and then weighed according to the doping amount of aluminum-titanium of 4.5%. Aluminum salt and titanium salt were mixed by dry ball milling at a speed of 300 rad / min for 4 h. After sieving, they were sintered in an air atmosphere in a muffle furnace. The sintering procedure was: Raise the temperature to 830°C, keep it warm for 12 hours, then cool to room temperature with the furnace, and obtain aluminum-titanium double-doped lithium manganate after sieving.

[0040] 2. Preparation of the spherical material of the 523-type ternary material: Weigh an appropriate amount of lithium salt, 523 precursor, and zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com