Negative plate and lithium ion battery comprising same

A negative electrode and negative electrode technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of insufficient battery cycle life, low porosity of the electrode sheet, and limited ability to improve battery performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

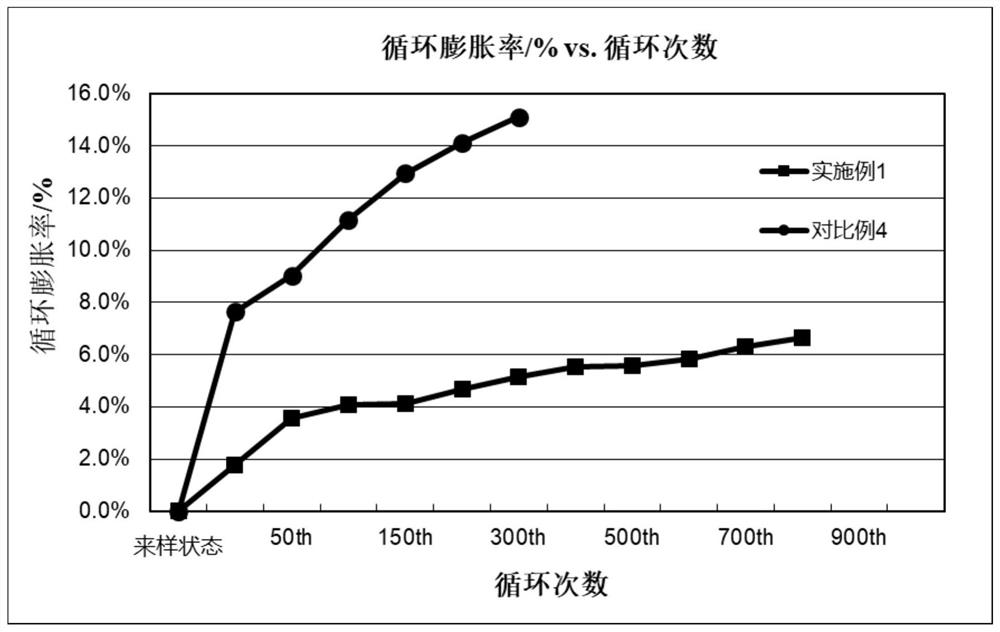

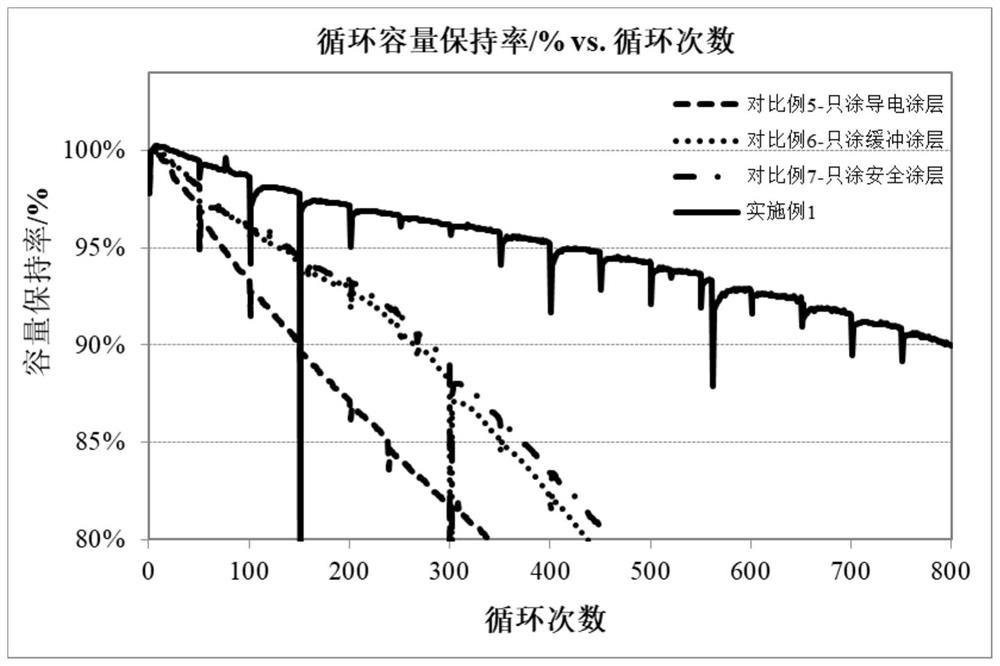

Embodiment 1

[0092] (1) Preparation of positive electrode sheet:

[0093] The cathode active material LiCoO 2 , the binder PVDF, and the conductive agent Super P are dissolved in N-methylpyrrolidone (NMP) according to the mass ratio of 97%: 1.5%: 1.5%, and stirred evenly to make a slurry, and evenly coated on both sides of the aluminum foil of the positive electrode current collector On the surface, it is baked at 100-150°C for 4-8 hours, and then cold-pressed and cut to make positive electrodes for lithium-ion batteries, with a compacted density of 4.1g / cm 3 , the thickness of the positive electrode active material layer on one side is 62 μm.

[0094] (2) Preparation of negative electrode conductive paste:

[0095] Super P and PVDF were mixed and dissolved in NMP at a mass ratio of 97:3 to obtain a conductive coating paste with a solid content of 45%.

[0096] (3) Preparation of negative electrode first negative electrode slurry:

[0097]Artificial graphite, conductive agent SP, SBR a...

Embodiment 2

[0110] The difference between this embodiment and Example 1 is: replace Super P in the conductive coating with carbon nanotubes, replace acetylene black in the buffer coating with Ketjen Black, and use zirconium nitride ceramics (D 90 ≤2μm) to replace alumina ceramics in safety coatings.

Embodiment 3

[0112] The difference between this example and Example 1 is that the thickness of the coating layer on the surface of the negative electrode current collector is different, as shown in Table 1; the compacted density of the negative electrode sheet is 1.55g / cm 3 ; Due to the change of the pressure density of the negative electrode sheet, adjust the thickness of the positive electrode active material layer on one side of the positive electrode sheet to 22 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com