Lithium ion battery ferrous oxalate composite negative electrode material and preparation method thereof

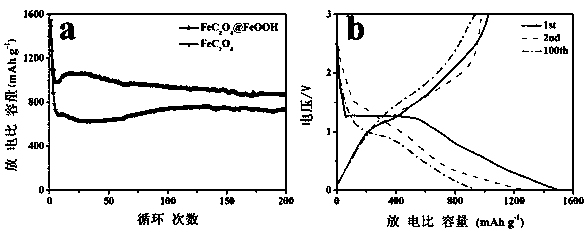

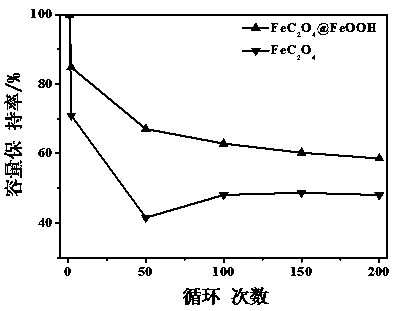

A lithium-ion battery, ferrous oxalate technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of high irreversible capacity and poor cycle performance of metal oxalate negative materials, and improve reversible capacity and cycle performance. Stability, improved high rate and long cycle performance, improved electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

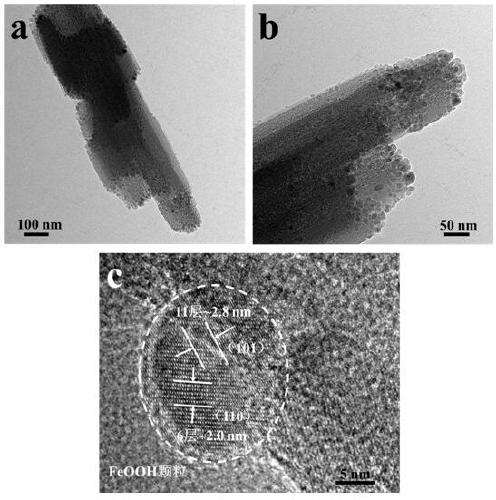

[0020] Embodiment 1: the preparation method of the lithium-ion battery ferrous oxalate composite negative electrode material of this surface coating FeOOH is as follows:

[0021] (1) Add ferrous sulfate to deionized aqueous solution, stir until completely dissolved to obtain a ferrous sulfate solution with a mass concentration of 8%; add dihydrate oxalic acid to absolute ethanol, stir until completely dissolved to obtain a colorless solution with a mass concentration of 15% Transparent oxalic acid solution; mix the above two solutions and stir for 1 hour, transfer the mixed suspension to a high-temperature and high-pressure reactor, and react at 60°C for 12 hours; after the reaction is complete, cool to room temperature, and dilute The yellow reaction product was centrifuged and washed with deionized water and absolute ethanol to remove water-soluble impurities, then placed in a vacuum drying oven and dried at 80°C to obtain ferrous oxalate dihydrate, wherein the molar ratio of...

Embodiment 2

[0028] Embodiment 2: the preparation method of the ferrous oxalate composite negative electrode material of the lithium ion battery of this surface coating FeOOH is as follows:

[0029] (1) Add ferrous sulfate to deionized aqueous solution, stir until completely dissolved to obtain a ferrous sulfate solution with a mass concentration of 15%; add dihydrate oxalic acid to absolute ethanol, stir until completely dissolved to obtain a mass concentration of 5% transparent oxalic acid solution; mix the above two solutions and stir for 2 hours, transfer the mixed suspension to a high-temperature and high-pressure reactor, and react at 100°C for 8 hours; after the reaction is complete, cool to room temperature, and The light yellow reaction product was separated by centrifugation, washed with deionized water and absolute ethanol to remove water-soluble impurities, and then placed in a vacuum drying oven and dried at 60°C to obtain ferrous oxalate dihydrate, wherein the molar ratio of f...

Embodiment 3

[0035] Embodiment 3: the preparation method of the lithium-ion battery ferrous oxalate composite negative electrode material of this surface coating FeOOH is as follows:

[0036] (1) Add ferrous sulfate to deionized aqueous solution, stir until completely dissolved to obtain a ferrous sulfate solution with a mass concentration of 20%; add dihydrate oxalic acid to absolute ethanol, stir until completely dissolved to obtain a colorless solution with a mass concentration of 10% Transparent oxalic acid solution; mix the above two solutions and stir for 3 hours, transfer the mixed suspension to a high-temperature and high-pressure reactor, and react at 50°C for 24 hours; after the reaction is complete, cool to room temperature, and dilute The yellow reaction product was centrifuged and washed with deionized water and absolute ethanol to remove water-soluble impurities, then placed in a vacuum drying oven and dried at 60°C to obtain ferrous oxalate dihydrate, wherein the molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com