High-energy-density long-cycle lithium iron phosphate battery

A lithium iron phosphate battery, high energy density technology, applied in the direction of lithium batteries, secondary batteries, battery electrodes, etc., can solve the problems of difficult to break through the use temperature, difficult use environment, poor rate performance, etc., to achieve relief materials Effects of volume change, reduced continuous decomposition, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

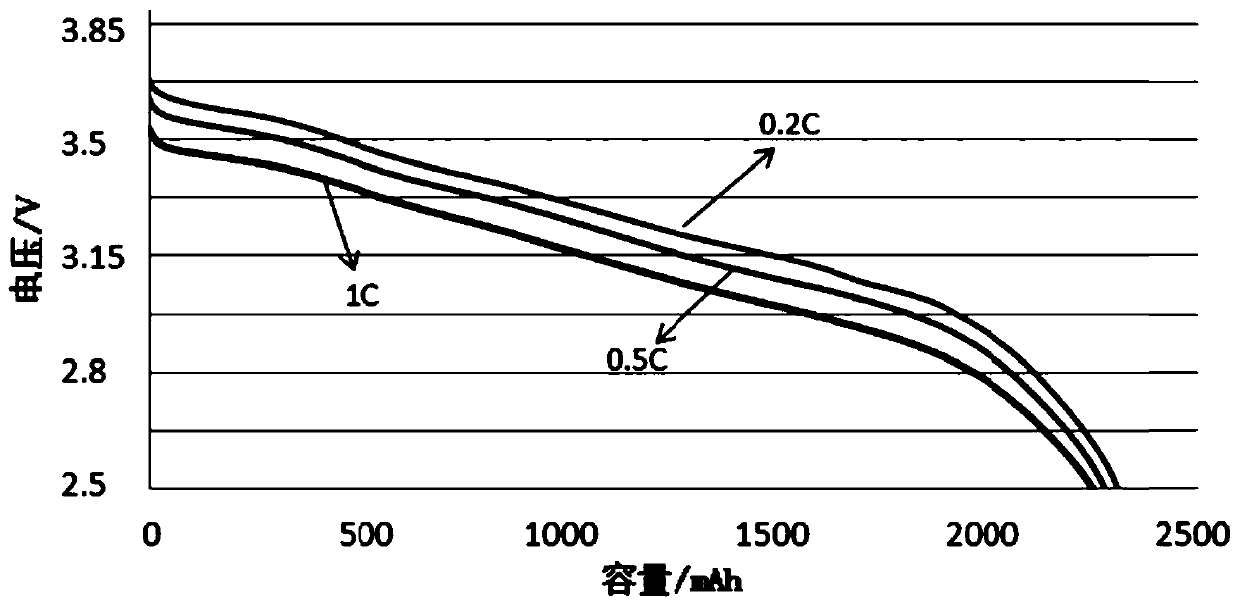

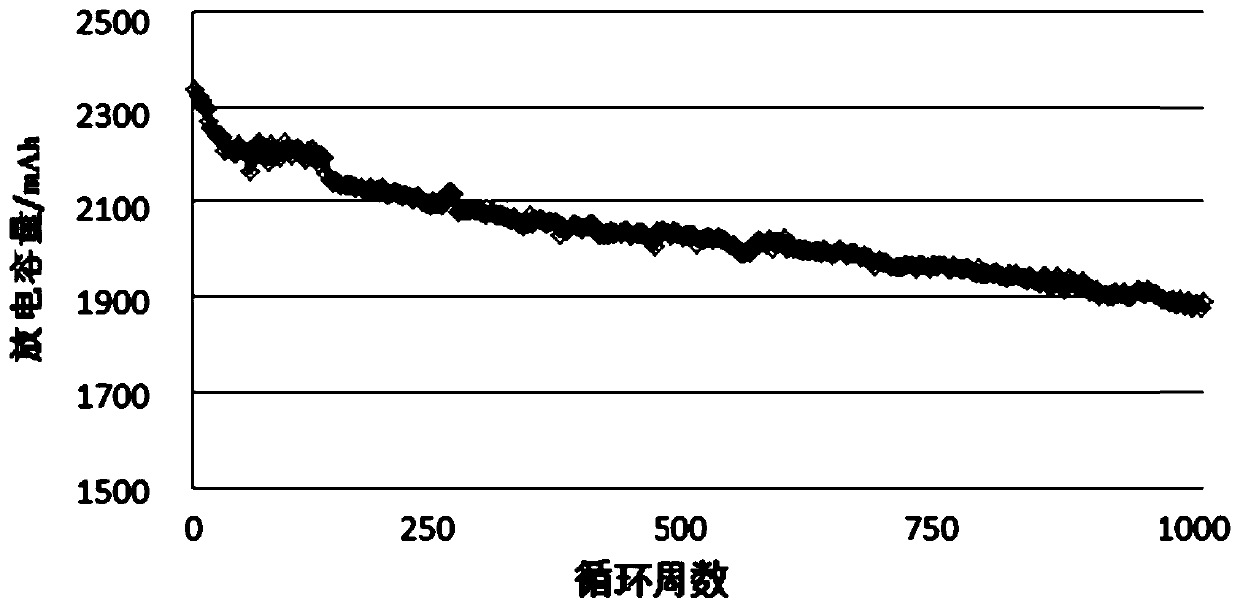

Embodiment 1

[0057] A high-energy density long-cycle lithium iron phosphate battery, comprising a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte and an outer casing; wherein, the positive electrode sheet is a mixture composed of a positive electrode active material, a conductive agent and a binder uniformly coated on 1.5 Made of μm metal aluminum foil on both sides, the rolling thickness is 148 μm, and the rolling compaction density is 2.35 g / cm m 3 , the slitting width is 58mm; the negative electrode sheet is made by uniformly coating the mixture of negative electrode active material, conductive agent and binder on both sides of 5μm metal copper foil, the rolling thickness is 148μm, and the rolling compaction density is 2.2 g / cm 3 , the slitting width is 58mm. The mass of the obtained battery is 39.86g.

[0058] The positive electrode active material is lithium iron phosphate doped with vanadium, boron, nitrogen and carbon elements, and its structure i...

Embodiment 2

[0061] A high-energy density long-cycle lithium iron phosphate battery, comprising a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte and an outer shell; wherein, the positive electrode sheet is a mixture composed of a positive electrode active material, a conductive agent and a binder uniformly coated on a 2 μm surface. It is made of metal aluminum foil on both sides, the rolling thickness is 147μm, and the rolling compaction density is 2.3g / cm 3 , the slitting width is 59mm; the negative electrode sheet is made by uniformly coating the mixture of negative electrode active material, conductive agent and binder on both sides of 6.5μm metal copper foil, the rolling thickness is 149μm, and the rolling compaction density 2.3g / cm 3 , the slitting width is 59mm. The mass of the obtained battery is 40.24g.

[0062] The positive electrode active material is lithium iron phosphate doped with vanadium, boron, nitrogen and carbon elements, and its stru...

Embodiment 3

[0065] A high-energy density long-cycle lithium iron phosphate battery, comprising a positive electrode sheet, a negative electrode sheet, a separator, an electrolyte and an outer shell; wherein, the positive electrode sheet is a mixture composed of a positive electrode active material, a conductive agent and a binder uniformly coated on 3.5 Made of μm metal aluminum foil on both sides, the rolling thickness is 150 μm, and the rolling compaction density is 2.45g / cm m 3 , the slitting width is 58.5mm; the negative electrode sheet is made by uniformly coating the mixture of negative electrode active material, conductive agent and binder on both sides of 6μm metal copper foil, the rolling thickness is 150μm, and the rolling compaction density 2.33g / cm 3 , the slitting width is 58.5mm. The mass of the obtained battery is 40.18g.

[0066] The positive electrode active material is lithium iron phosphate doped with vanadium, boron, nitrogen and carbon elements, and its structure is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com