Lithium ion battery cathode and lithium ion battery therewith

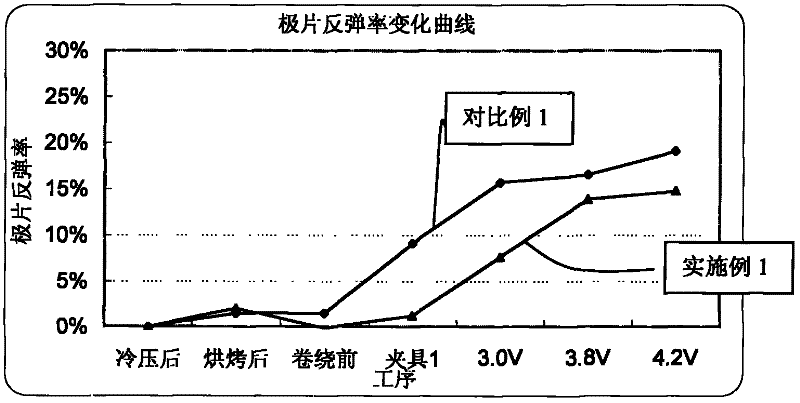

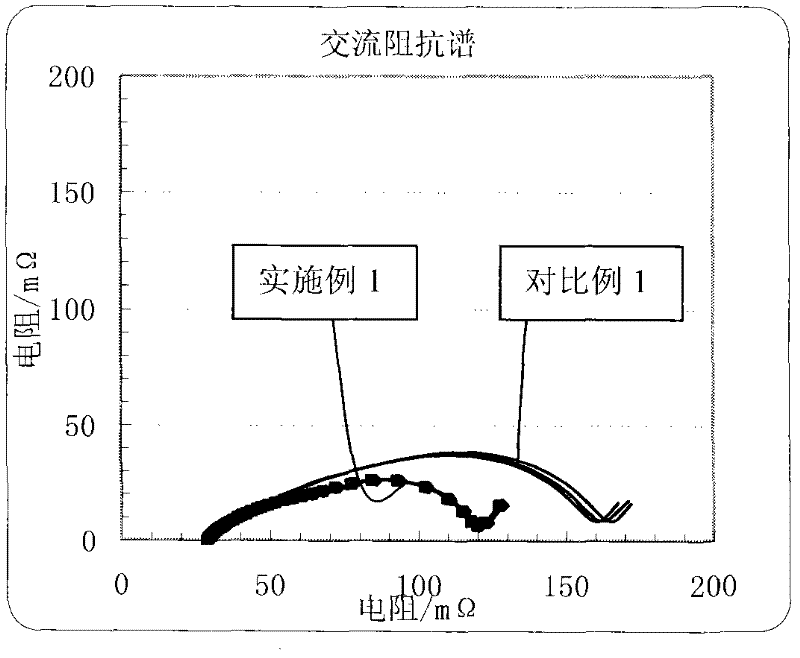

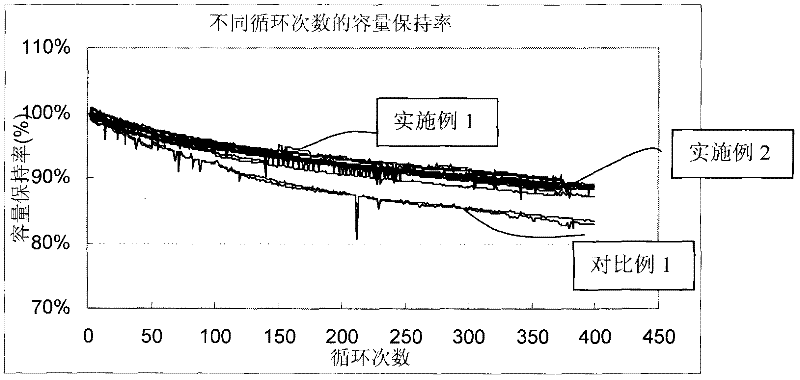

A lithium-ion battery and negative electrode technology, which is applied in the field of lithium-ion battery composition, can solve the problems of poor cycle life characteristics of lithium batteries, large changes in battery thickness, and poor adhesion of anode sheets, etc., to ensure long-term cycle performance. Good long-term cycle characteristics and the effect of reducing battery expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Negative sheet preparation process

[0026] Negative electrode slurry formula is based on dry material weight percentage, is made up of three parts: 2.5% sodium carboxymethyl cellulose (CMC-Na), 1.5% conductive carbon black, 96% negative electrode active material, wherein negative electrode active material adopts artificial graphite, carboxy Sodium methylcellulose has a number average molecular weight of about 500,000, a 1% aqueous solution viscosity of 150 mPa.s at 25°C, and a degree of substitution of 0.8. During the preparation of the slurry, the solvent is water, and water accounts for 60% of the total slurry.

[0027] First, add water and sodium carboxymethyl cellulose into the stirring grinder according to the above formula, and dissolve completely in a vacuum state, then add conductive carbon black into the dissolved water-based polymer solution according to the formula, and quickly stir and grind Until the fineness is below 5μm, finally add artificial graphite ...

Embodiment 2

[0036] The difference from Example 1 is that: the negative electrode formula contains 97.5% of the negative electrode active material, 1% of sodium carboxymethylcellulose, and 1.5% of conductive carbon black as an electrical conduction aid. Wherein the sodium carboxymethyl cellulose substitution degree that adopts is 1.0, molecular weight 1,000,000, its 1% aqueous solution 25 ℃ viscosity 1200mPa.s, other is identical with embodiment 1, repeats no more here.

Embodiment 3

[0038] The difference from Example 1 is that: the negative electrode formula contains 93.5% of the negative electrode active material, 5% sodium carboxymethyl cellulose, and 1.5% conductive carbon black as an electrical conduction aid. Wherein the sodium carboxymethylcellulose that adopts is 0.6, molecular weight 50,000, its 1% aqueous solution 25 ℃ viscosity 50mPa.s, other is identical with embodiment 1, repeats no more here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com