Cleaning method for effectively removing particle agglomeration on front and back sides of wafer

A kind of particle agglomeration, front and back technology, applied in the direction of cleaning method using tools, cleaning method using liquid, cleaning method and utensils, etc., can solve the problem that the agglomerated particles are difficult to be effectively removed, reduce the output benefit of epitaxial wafers, and the cleaning process Complicated and cumbersome problems, to achieve the effect of improving the efficiency of epitaxy, improving cleaning efficiency and cleaning quality, and improving cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The accompanying drawings are only for reference and description, and do not constitute a limitation to the protection scope of the present invention.

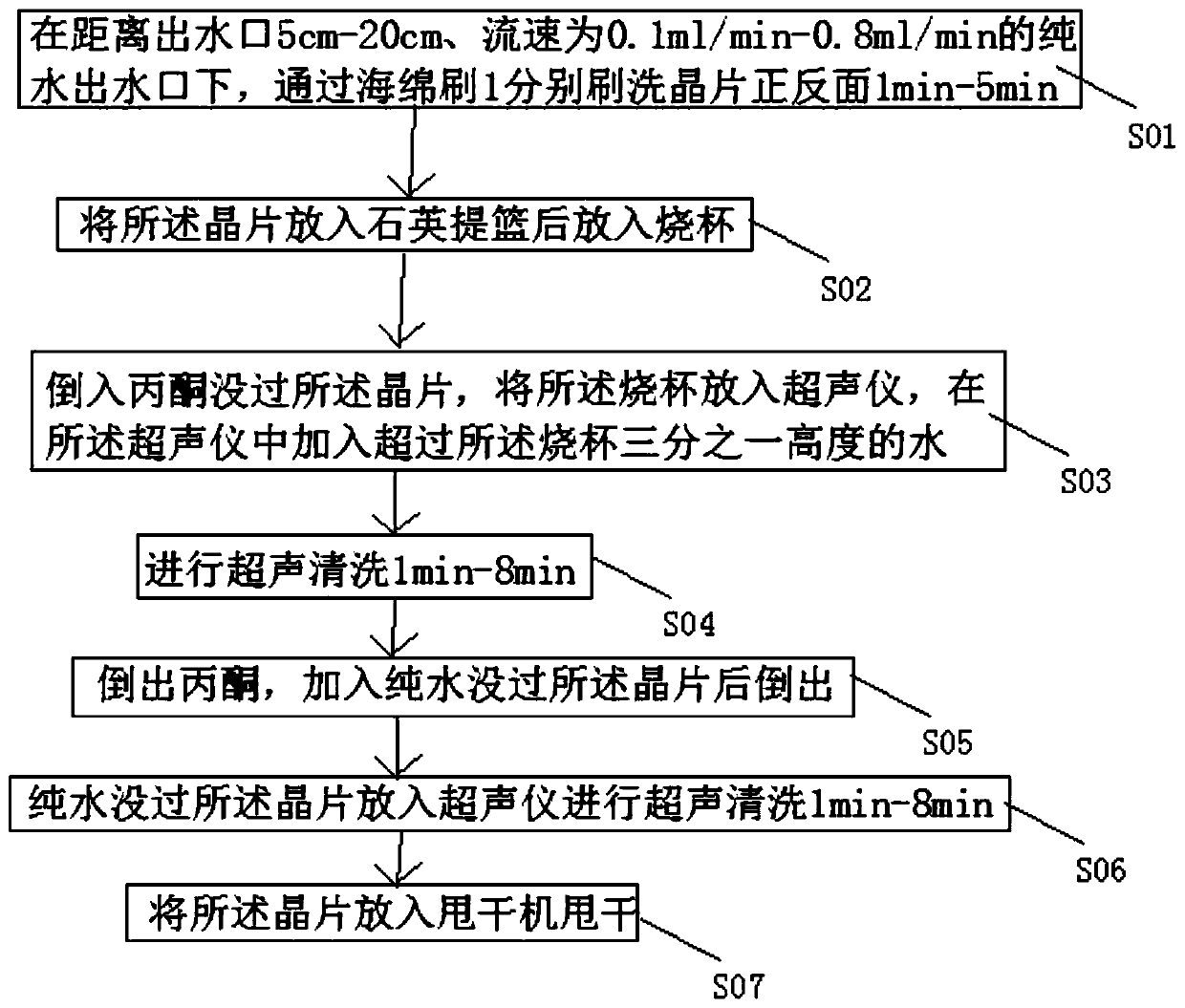

[0033] Please refer to Figure 1 to Figure 3 , a cleaning method for effectively removing particle agglomeration on the front and back sides of the wafer of the present invention, comprising the following steps:

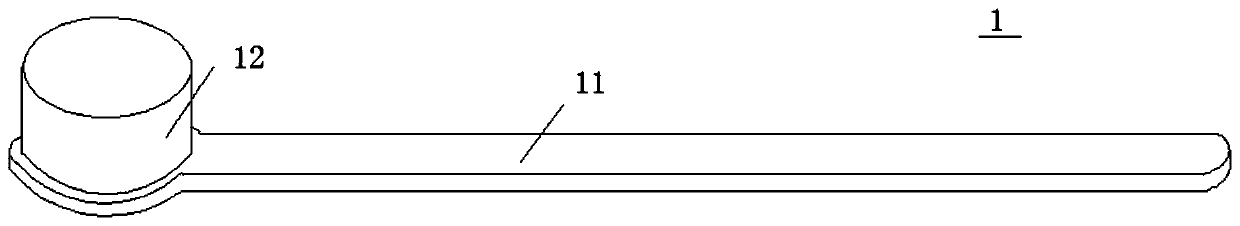

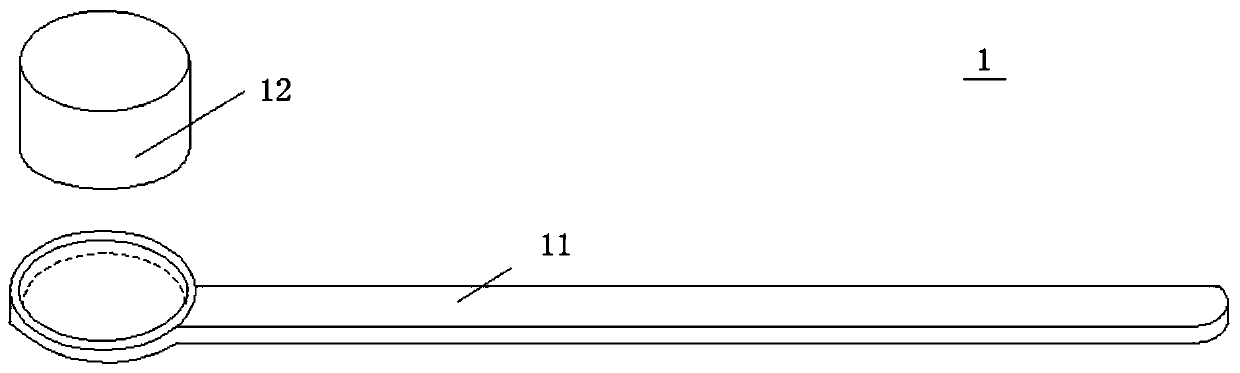

[0034] S01, under the pure water outlet with a distance of 5cm-20cm from the water outlet and a flow rate of 0.1ml / min-0.8ml / min, use the sponge brush 1 to scrub the front and back of the wafer for 1min-5min respectively. Specifically, brush the front and back sides of the wafer with a sponge brush 1 for 1 min- It should be noted that the flow rate is controlled by a valve. Further, the sponge brush 1 includes: a long handle 11, a sponge head 12 detachably arranged at one end of the lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com