Curved glass washing device and using method

A glass cleaning and arc bending technology, which is applied in the directions of cleaning methods, cleaning methods and utensils using liquids, and cleaning methods using tools, etc., can solve the problems of affecting production efficiency, low production efficiency, and small arc radius of curved glass. , to achieve the effect of improving product quality and production efficiency, high cleaning quality and cleaning efficiency, and reducing personnel work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

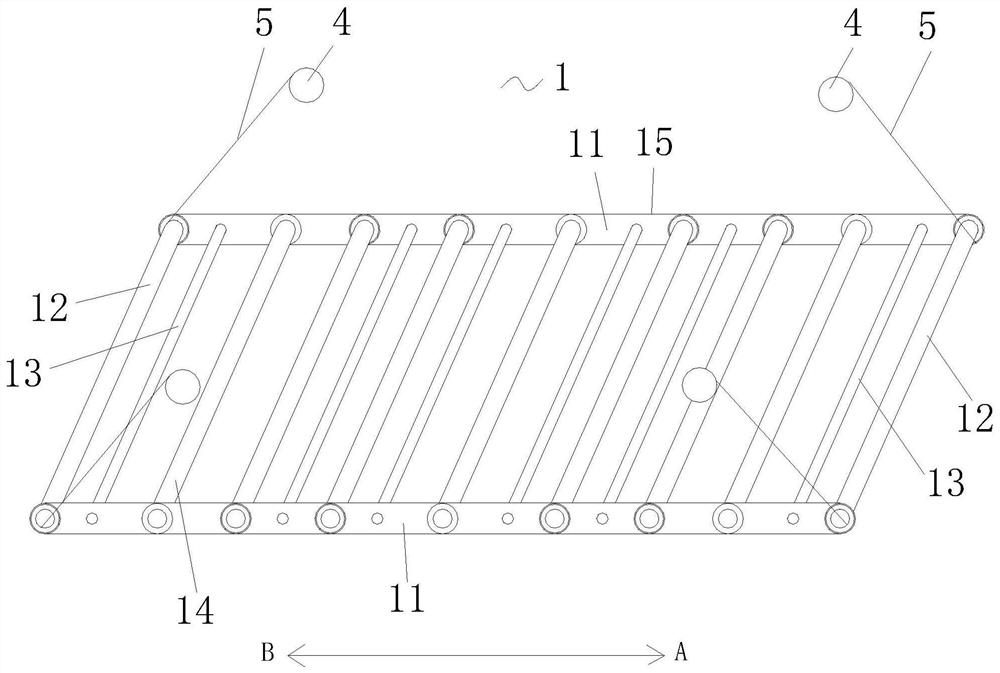

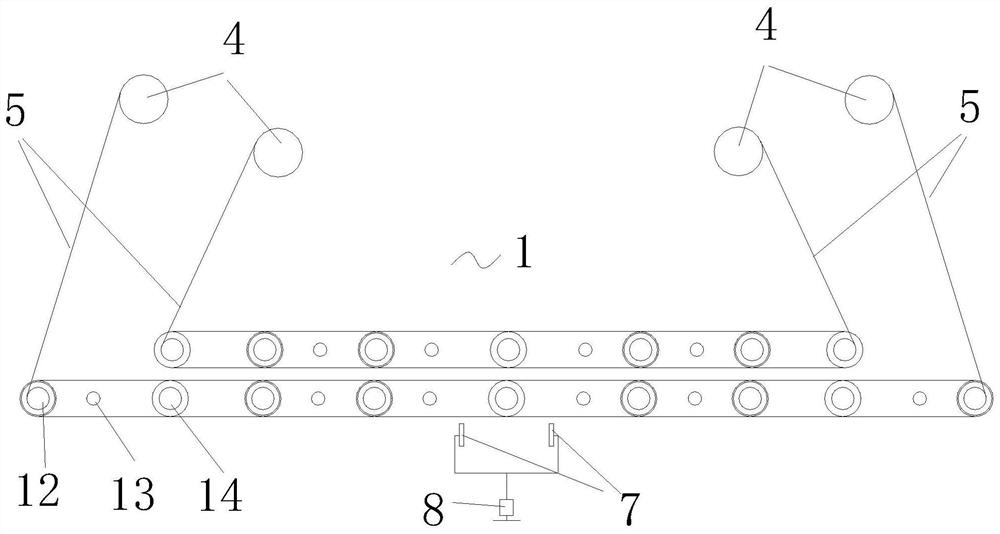

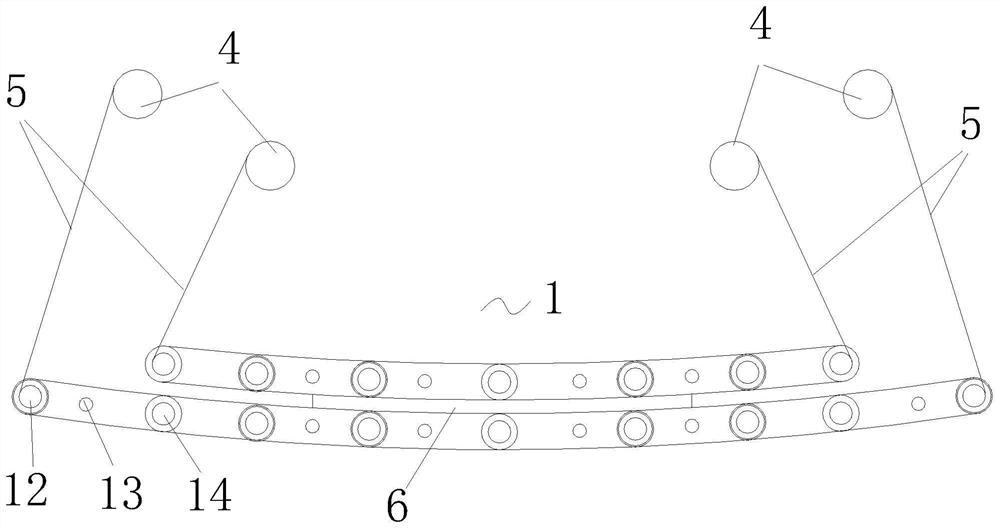

[0039] The specific structure of the cleaning mechanism 1 is as follows: it includes an upper cleaning assembly and a lower cleaning assembly, and a first drive unit that are arranged opposite to each other up and down. There is a space for placing curved glass to be cleaned between the upper cleaning assembly and the lower cleaning assembly. The assembly and the lower cleaning assembly include a deformable first roller table support 11, a plurality of first transmission rollers 12 and a cleaning pipe 13 arranged on the first roller table support 11, and a plurality of first transmission rollers 12 and cleaning pipes 13 are all Along the conveying direction of curved glass (see figure 1 In the direction of the middle arrow, A refers to the front, and B refers to the rear), and the first drive roller 12 is parallel to the axial direction of the cleaning pipe 13, and the first driving unit is connected to the front and rear ends of the upper cleaning assembly and the lower cleani...

Embodiment 2

[0047] The concrete structure of the first air-drying mechanism 2 is as follows: see Figure 4 , including the first upper air-drying assembly, the first lower air-drying assembly, and the second drive unit that are arranged up and down oppositely. There is a space for placing the curved glass to be air-dried between the first upper air-drying assembly and the first lower air-drying assembly. The assembly and the first lower air-drying assembly include a deformable second roller table support 21, a plurality of second drive rollers 22 arranged on the second roller table support 21, a first blowing unit 23, a plurality of second drive rollers 22, The first blowing unit 23 is all arranged along the transmission direction of the curved glass (see Figure 4 The direction indicated by the middle arrow, A refers to the front, B refers to the back), and the second driving roller 22 is parallel to the axial direction of the first blowing unit 23, the second roller table support 21 is ...

Embodiment 3

[0054] The concrete structure of the second air-drying mechanism 3 is as follows: see Figure 5 , which includes a second upper air-drying assembly, a second lower air-drying assembly, and a second drive unit that are arranged up and down oppositely. There is a space between the second upper air-drying assembly and the second lower air-drying assembly to place curved glass to be air-dried. The air-drying assembly and the second lower air-drying assembly include a support frame, a deformable third roller table support 31, a plurality of deformable third transmission rollers 32 arranged on the support frame and the third roller table support 31, and a deformable first roller table support 31. Two blowing units 33, a plurality of the third drive rollers 32, and the second blowing unit 33 are all arranged along the conveying direction of the curved glass (see Figure 5 The direction indicated by the middle arrow, A refers to the front, and B refers to the rear), and the third roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com