High-efficiency cleaning device for precise workpieces

A technology for cleaning equipment and workpieces, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor cleaning quality, low cleaning efficiency, and small application range of precision workpieces, and achieve Improve cleaning efficiency and cleaning quality, improve cleaning quality and cleaning efficiency, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

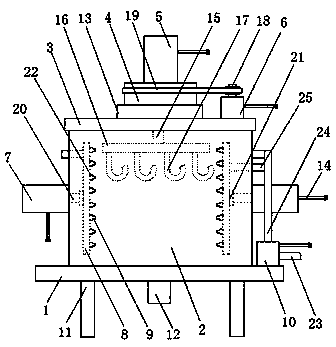

[0018] as attached figure 1 As shown, a high-efficiency cleaning equipment for precision workpieces includes a bottom plate 1, a cleaning chamber 2, a top cover 3, a rotating disk 4, cylinder one 5, a motor 6, cylinder two 7, a push plate 8, a water spray pipe 9 and a water delivery pump 10. It is characterized in that: the bottom plate 1 is set on the bracket 11, the cleaning chamber 2 is set on the bottom plate 1, and a drain pipe 12 is set on the cleaning room 2, and the top cover 3 is set on the cleaning chamber 2, and a fixed bearing 13 is arranged on the top cover 3, the rotating disk 4 is arranged in the fixed bearing 13, the cylinder one 5 is arranged on the rotating disk 4, and the cylinder one 5 is provided with Power cord 14, piston rod one 15, described motor 6 is arranged on cleaning chamber 1 top, and is provided with power cord 14, driving wheel 18 on motor 6, and described cylinder two 7 is arranged on cleaning chamber 1 side wall , and on cylinder two 7, be p...

Embodiment 2

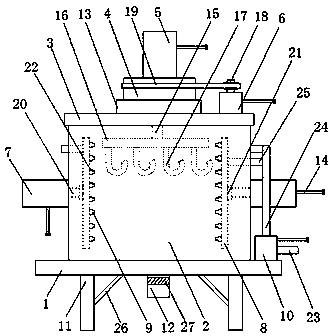

[0026] as attached figure 2 As shown, a high-efficiency cleaning equipment for precision workpieces includes a bottom plate 1, a cleaning chamber 2, a top cover 3, a rotating disk 4, cylinder one 5, a motor 6, cylinder two 7, a push plate 8, a water spray pipe 9 and a water delivery pump 10. It is characterized in that: the bottom plate 1 is set on the bracket 11, the cleaning chamber 2 is set on the bottom plate 1, and a drain pipe 12 is set on the cleaning room 2, and the top cover 3 is set on the cleaning chamber 2, and a fixed bearing 13 is arranged on the top cover 3, the rotating disk 4 is arranged in the fixed bearing 13, the cylinder one 5 is arranged on the rotating disk 4, and the cylinder one 5 is provided with Power cord 14, piston rod one 15, described motor 6 is arranged on cleaning chamber 1 top, and is provided with power cord 14, driving wheel 18 on motor 6, and described cylinder two 7 is arranged on cleaning chamber 1 side wall , and on cylinder two 7, be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com