Magnesium alloy workpiece pre-weld surface laser cleaning method

A laser cleaning and magnesium alloy technology, applied in the field of laser cleaning, can solve problems such as restrictions on large-scale popularization and application, welding quality impact, gas human body and environmental damage, etc., and achieve the goal of improving the cleaning work site environment, cleaning efficiency and cleaning quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

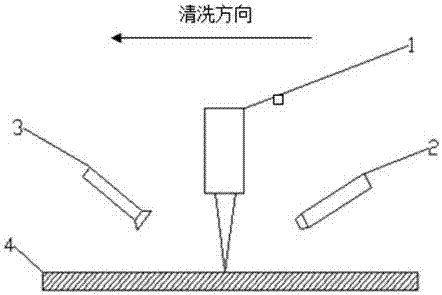

Image

Examples

Embodiment 1

[0039] In the laser cleaning step, the laser power of the pulsed fiber laser is set to 150W, usually 150W, which is suitable for cleaning most oxide layers, with a pulse width of 25ns, a pulse frequency of 25KHz, and a scan rate of 3500mm / s.

Embodiment 2

[0041] In the laser cleaning step, the laser power of the pulsed fiber laser is set to 100W. Depending on the thickness of the oxide layer, the laser power of the pulsed fiber laser is appropriately reduced to reduce energy consumption. The pulse width is 20ns, the pulse frequency is 20KHz, and the scan rate is 3000mm / s.

Embodiment 3

[0043]In the laser cleaning step, the laser power of the pulsed fiber laser is set to 200W, the maximum power is turned on, the cleaning speed is fast, and the work efficiency is improved. The pulse width is 30ns, the pulse frequency is 30KHz, and the scanning rate is 4000mm / s.

[0044] In summary, the laser cleaning method for the surface of a magnesium alloy workpiece before welding pointed out by the present invention reduces the cleaning process, improves the cleaning efficiency, eliminates the need for enterprises to deal with waste liquid, basically has no loss of consumables, is environmentally friendly, and improves the cleaning working environment. Protect human health.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com