Cr-Ni-Mn-series non-magnetic stainless steel and preparation method thereof

A non-magnetic stainless steel and steel billet technology, applied in the field of stainless steel materials, can solve the problems of martensitic phase transformation, failure to apply, stainless steel deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

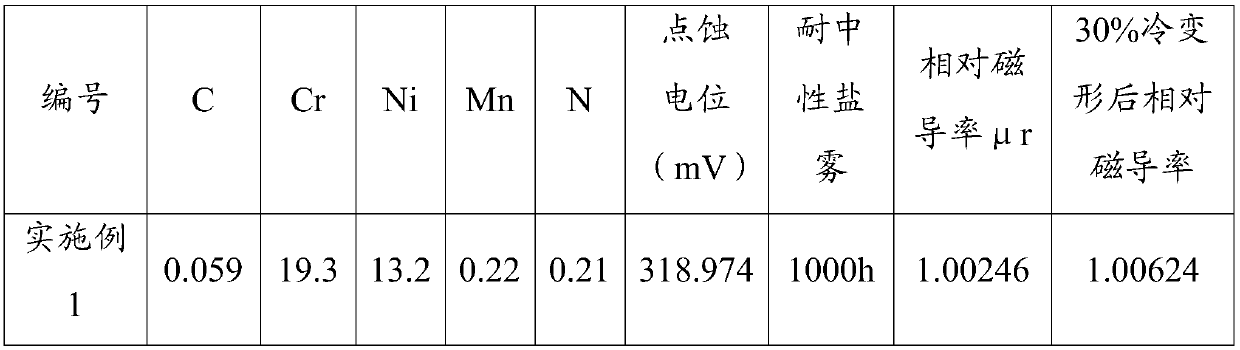

Examples

preparation example Construction

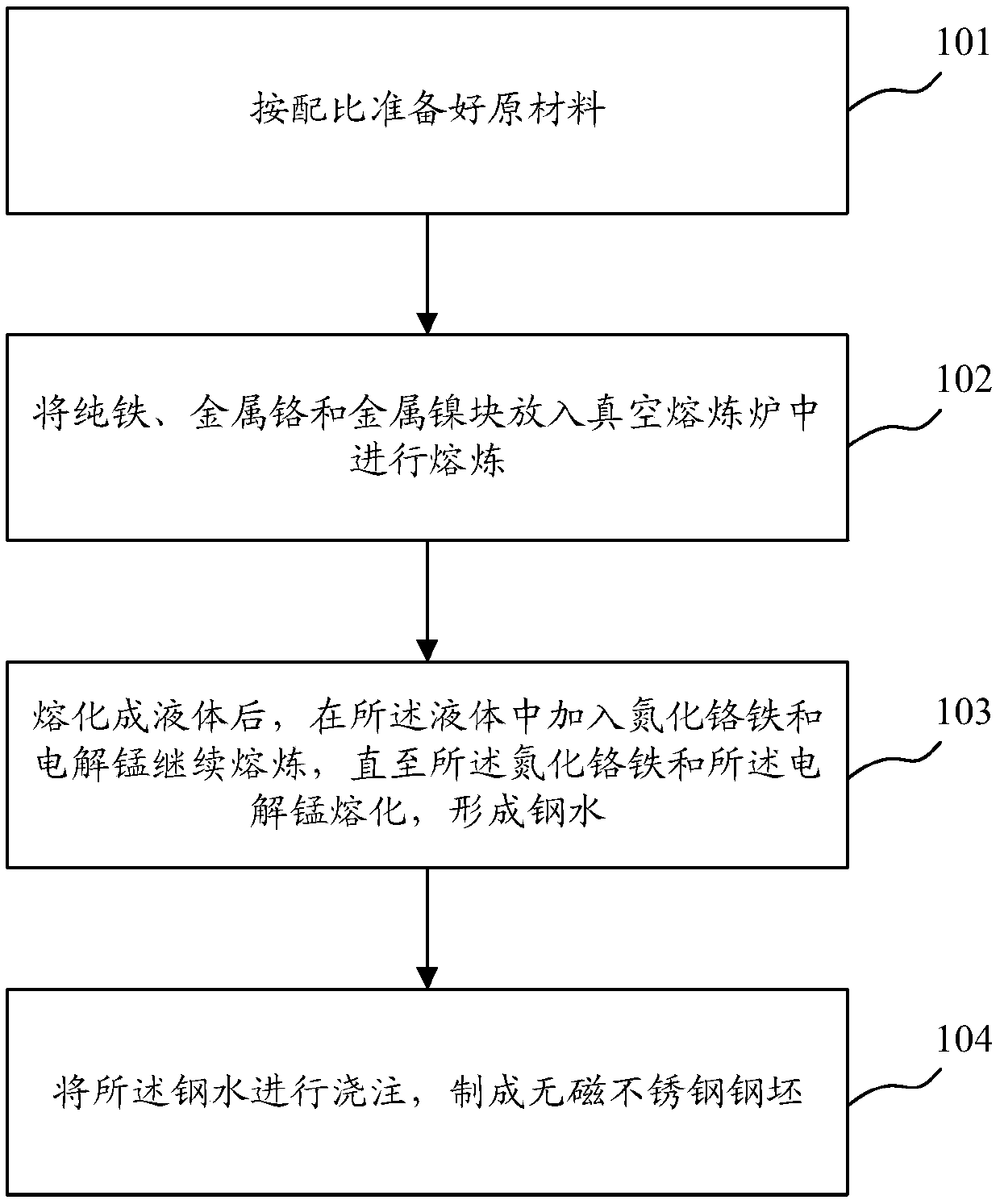

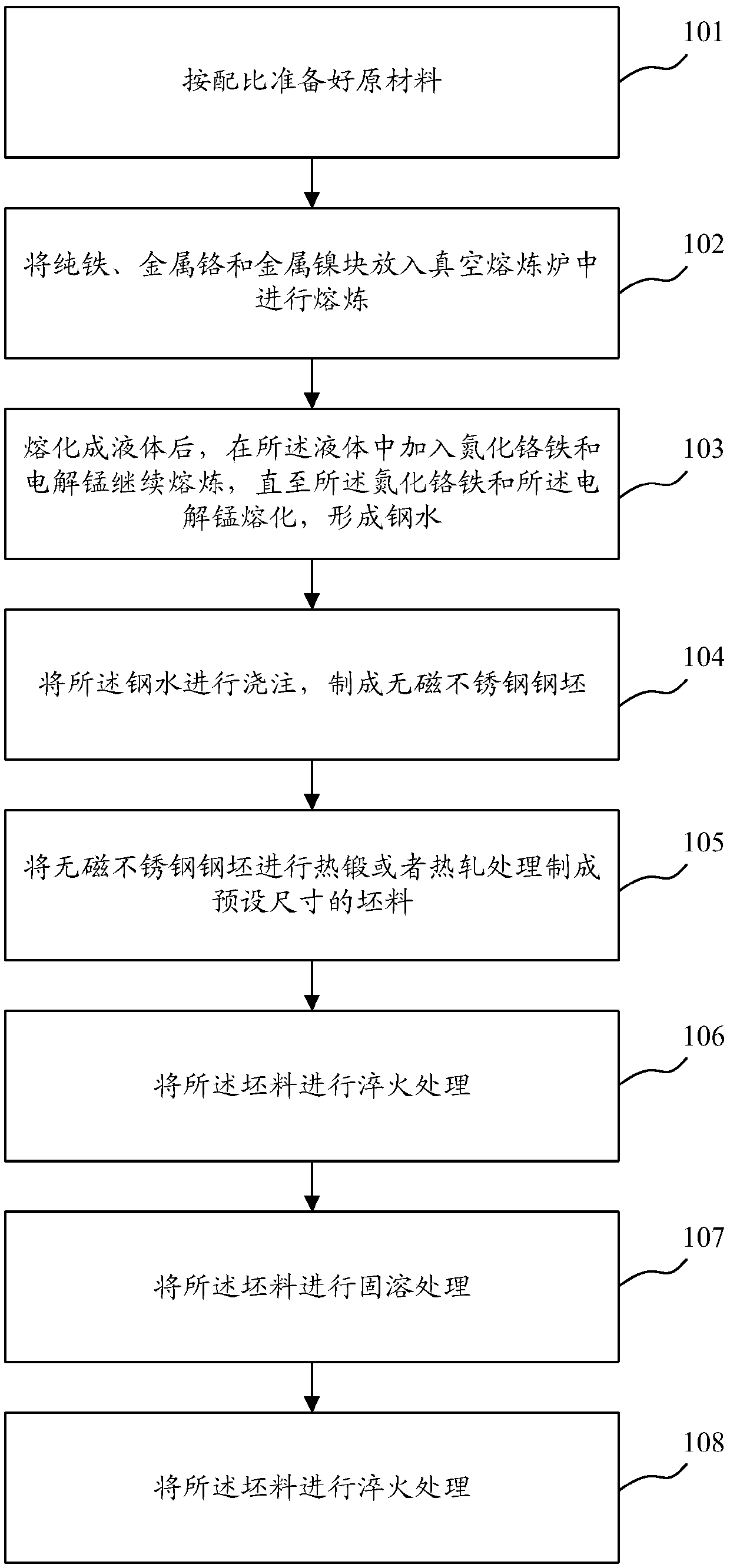

[0037] The embodiment of the present invention provides a kind of preparation method of Cr-Ni-Mn series non-magnetic stainless steel, such as figure 1 As shown, the preparation method mainly includes the following steps:

[0038] Step 101: Prepare raw materials according to the ratio.

[0039] Here, the raw materials may include pure iron, metallic chromium, metallic nickel block ferrochromium nitride, and electrolytic manganese, wherein electrolytic manganese may be electrolytic manganese block, electrolytic manganese particles, electrolytic manganese powder, and the like.

[0040] In actual application, the ratio of various raw materials can be respectively: 60.36-69.67wt% for pure iron, 13.64-16.58wt% for metal chromium, 12-14wt% for metal nickel block, and 4.69-7.81wt% for ferrochrome nitride %, electrolytic manganese≤1.25wt%.

[0041] Here, wt% means mass percentage.

[0042] Step 102: Put the pure iron, metal chromium and metal nickel blocks into a vacuum melting furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com