Preparation method of polyhydroxyalkanoate/polypyrrole composite electrospun membrane and electrospun membrane

A polyhydroxyalkanoate and electrospinning technology, which is applied in the field of medical biomaterials, can solve the problems of indeterminate properties, difficult to implement molding processes, complicated preparation methods, etc., achieves high universality in application scope, and is conducive to cell adhesion. The effect of simple growth and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A polyhydroxyalkanoate / polypyrrole composite electrospun membrane, its preparation process is as follows:

[0029] A preparation method of polyhydroxyalkanoate / polypyrrole composite electrospun membrane, comprising the steps of:

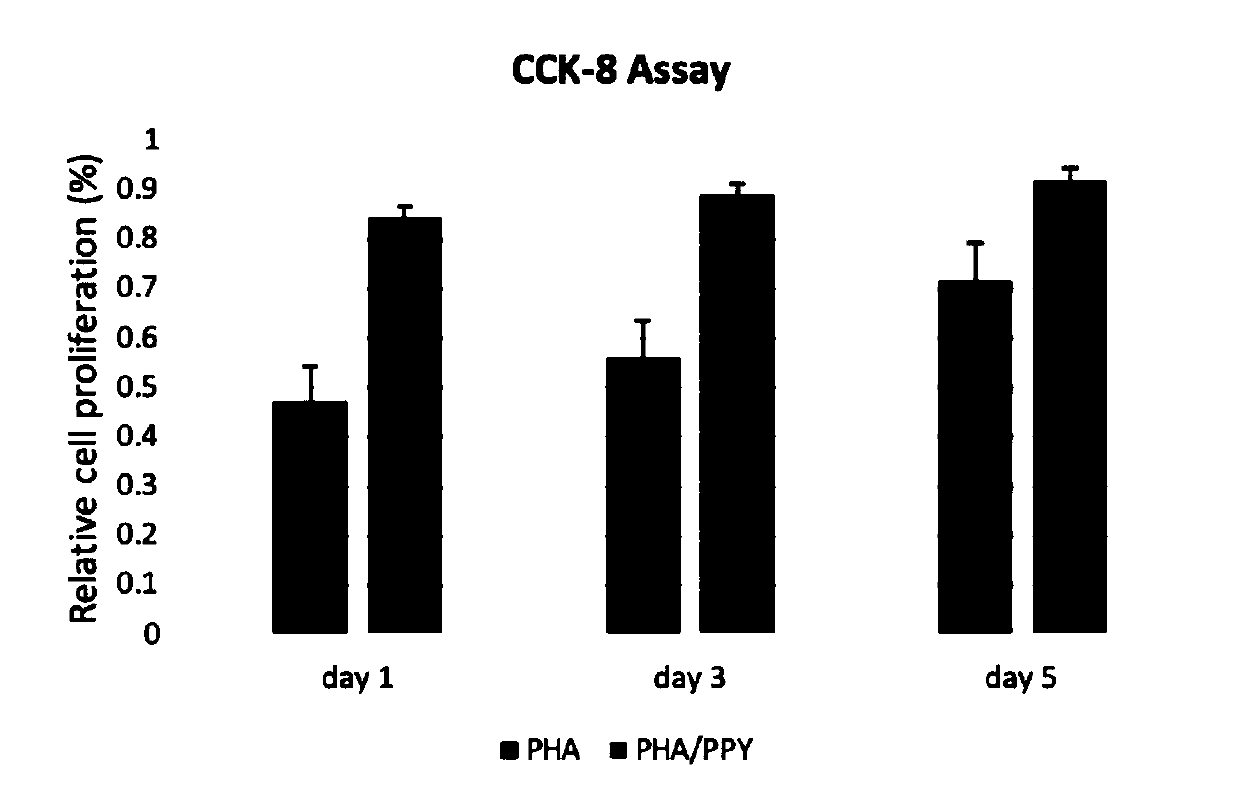

[0030] S1. Preparation of polyhydroxyalkanoate (PHA) nanofiber electrospun membrane: Weigh 1g of medical-grade PHA powder and dissolve it in 10mL of dichloromethane and dimethylformamide composite solvent (dichloromethane and dimethylformamide The volume ratio of formamide is 3:7), uniformly stirred to form a PHA solution with a concentration of 100mg / mL and added to a 1mL syringe, and the syringe was fixed with a needle nozzle. At room temperature, the distance between the needle and the receiver was set to 15 cm, the voltage was 15 kV, and the syringe advancing speed was 3.0 ml / hour, and the electrofilament was collected through ethanol solution. Subsequently, the obtained electrolike silk was washed three times with deionized water, and po...

Embodiment 2

[0033] A preparation method of polyhydroxyalkanoate / polypyrrole composite electrospun membrane, comprising the steps of:

[0034] S1. Preparation of polyhydroxyalkanoate (PHA) nanofiber electrospun membrane: Weigh 0.95g of medical-grade PHA powder and dissolve it in 10mL of dichloromethane and dimethylformamide composite solvent (dichloromethane and dimethylformamide The volume ratio of methyl formamide is 3:7), uniformly stirred to form a PHA solution with a concentration of 100mg / mL and added to a 1mL syringe, and the syringe was fixed with a needle nozzle. At room temperature, the distance between the needle and the receiver was set to 15 cm, the voltage was 15 kV, and the syringe advancing speed was 3.0 ml / hour, and the electrofilament was collected through ethanol solution. Subsequently, the obtained electrolike silk was washed three times with deionized water, and polyhydroxyalkanoate nanofibers were obtained after freeze-drying overnight. The above-mentioned nanofibers...

Embodiment 3

[0037] A preparation method of polyhydroxyalkanoate / polypyrrole composite electrospun membrane, comprising the steps of:

[0038] S1. Preparation of polyhydroxyalkanoate (PHA) nanofiber electrospun membrane: Weigh 1.05g of medical-grade PHA powder and dissolve it in 10mL of dichloromethane and dimethylformamide composite solvent (dichloromethane and dimethylformamide The volume ratio of methyl formamide is 3:7), uniformly stirred to form a PHA solution with a concentration of 100mg / mL and added to a 1mL syringe, and the syringe was fixed with a needle nozzle. At room temperature, the distance between the needle and the receiver was set to 15 cm, the voltage was 15 kV, and the syringe advancing speed was 3.0 ml / hour, and the electrofilament was collected through ethanol solution. Subsequently, the obtained electrolike silk was washed three times with deionized water, and polyhydroxyalkanoate nanofibers were obtained after freeze-drying overnight. The above-mentioned nanofibers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com