Zinc-containing fabric preparation method

A technology of fabrics and raw materials, which is applied in the field of preparation of zinc-containing fabrics, can solve the problems of reducing the firmness of zinc fibers, affecting the service life of fabrics, and reducing warmth retention, so as to reduce anti-pilling, reduce friction pilling, and improve warmth retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, a kind of preparation method of zinc-containing fabric, comprises the steps:

[0060] (1) Zinc fiber pretreatment: the zinc fiber is pretreated by oil agent;

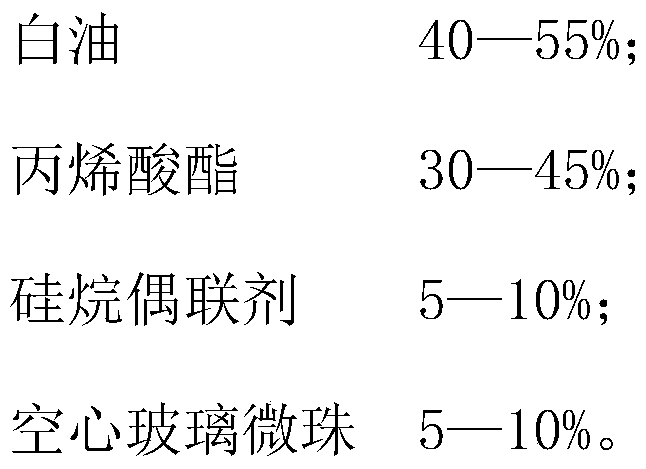

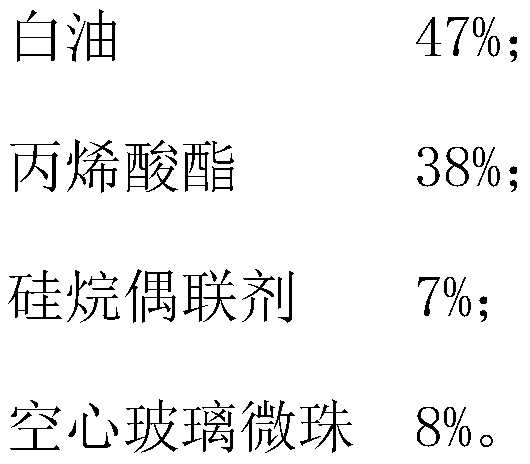

[0061] Described oil agent comprises the raw material of following percentage by weight:

[0062]

[0063] (2) Twisting: twisting pretreated zinc fibers with rayon, spandex, and wool fibers into zinc-containing fiber yarns;

[0064] Before rayon, spandex and zinc fiber are twisted, the rayon and spandex must be pretreated with the first pretreatment liquid, and the first pretreatment liquid includes the following raw materials in weight percentage:

[0065] softener 25%;

[0066] Soda ash 13%;

[0067] Deionized water 62%.

[0068] The washing temperature after the treatment with the first pretreatment liquid is 77°C.

[0069] Before the wool fiber and the zinc fiber are twisted, the wool fiber needs to be pretreated by the second pretreatment liquid, and the second pretreatment liquid inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com