Iron ore sintered biomass fuel and preparation method and application thereof

A biomass fuel and biomass technology, which is applied in the field of biomass sintering fuel to replace fossil fuels to achieve emission reduction, iron ore sintering fuel, and biomass sintering fuel, can solve the problems of large reactivity gap and asynchronous fuel combustion, etc. To achieve the effect of low volatile content, reducing damage, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

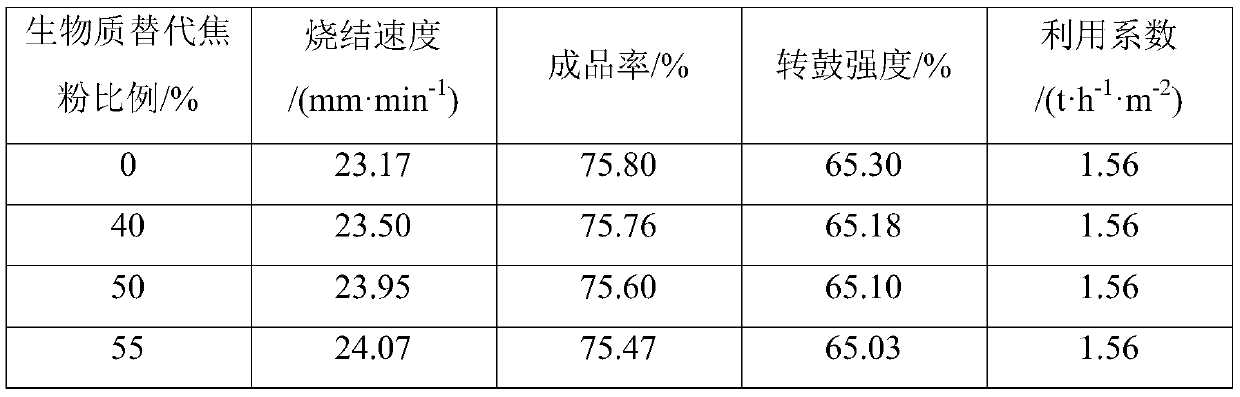

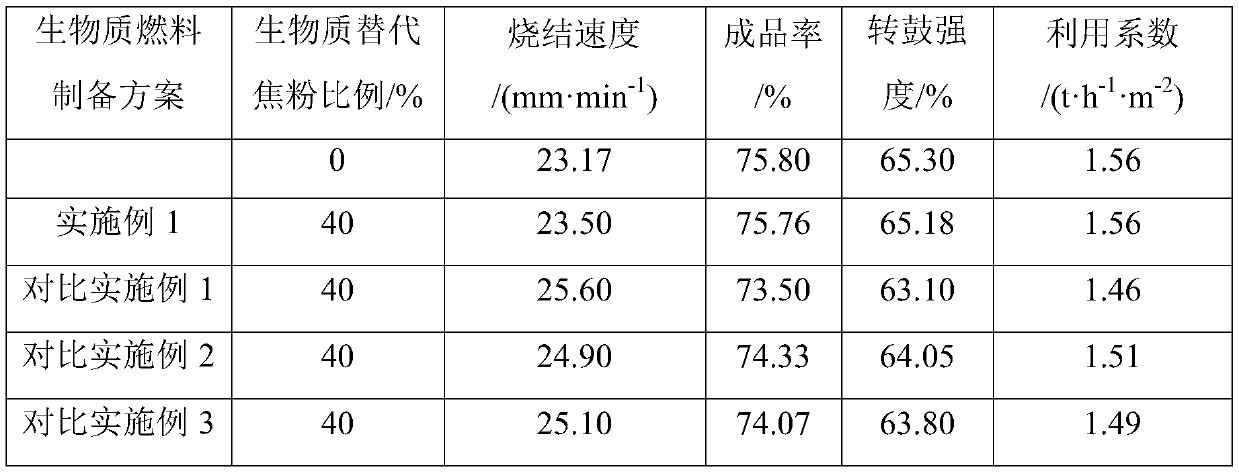

[0032] The mixed slag of cotton straw, iron beneficiation tailing slag and silica tailing slag (SiO 2 70%, Fe 2 O 3 30%) respectively grind to 0.2~0.6mm, 0~0.005mm, according to the mass percentage of 99%, 1% respectively, mix uniformly, and then under the mechanical pressure of 400kg / cm 3 , Compress the mixed biomass into biomass particles under the conditions of compression time 0.5min and room temperature. The particles are first heated to 200°C at a heating rate of 20°C / min and stayed for 30 minutes to complete low-temperature pretreatment. Then the particles are heated to 600°C at a heating rate of 5°C / min and stay for 15 minutes, and the carbonization process Keep the atmosphere at N 2 85%, Ar15%, gas flow rate is 0.05L / min. The prepared biomass has a combustion heat value of 27MJ / kg, a volatile content of 2.0%, and a specific surface area of 20m 2 / g, porosity is 19%, apparent density is 1.7g / cm 3 . Substituting 40% coke powder with fixed carbon content for iron ore...

Embodiment 2

[0034] The mixed slag of cotton straw, iron beneficiation tailing slag and silica tailing slag (SiO 2 60%, Fe 2 O 3 40%) respectively grind to 0.2~0.6mm, 0~0.005mm, according to the mass percentage of 98.5%, 1.5% respectively, mix uniformly, and then under the mechanical pressure of 500kg / cm 3 , Compress the mixed biomass into biomass particles under the conditions of compression time 1min and compression temperature 70℃. Heat the particles to 250°C at a heating rate of 15°C / min and stay for 40 minutes to complete the low-temperature pretreatment, then heat the particles to 650°C at a heating rate of 4°C / min, and stay for 20 minutes, the carbonization process Keep the atmosphere at N 2 85%, Ar 15%, gas flow rate is 0.05L / min. The prepared biomass has a combustion heat value of 28MJ / kg, a volatile content of 1.5%, and a specific surface area of 17m 2 / g, porosity is 16%, apparent density is 1.85g / cm 3 . Substituting 50% coke powder with fixed carbon content for iron ore sint...

Embodiment 3

[0036] The mixed slag of cotton straw, iron beneficiation tailing slag and silica tailing slag (SiO 2 80%, Fe 2 O 3 20%) respectively grind to 0.2~0.6mm, 0~0.005mm, according to the mass percentage of 98%, 2% respectively, mix uniformly, and then under the mechanical pressure of 600kg / cm 3 , Compress the mixed biomass into biomass particles under the conditions of compression time 1min and compression temperature 70℃. The particles are heated to 250°C at a heating rate of 15°C / min and stay for 40 minutes to complete the low-temperature pretreatment. Then the particles are heated to 700°C at a heating rate of 3°C / min and stay for 25 minutes, and the carbonization process Keep the atmosphere at N 2 85%, Ar 15%, gas flow rate is 0.05L / min. The prepared biomass has a combustion heat value of 30MJ / kg, a volatile content of 1.2%, and a specific surface area of 15m 2 / g, porosity is 14%, apparent density is 2.0g / cm 3 . Substituting its fixed carbon content for 55% of coke powder f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com