A kind of strontium α-calcium sulfate hemihydrate/nano silver/ginsenoside-loaded sodium alginate microsphere bone substitute material and preparation method thereof

A technology of calcium sulfate hemihydrate and sodium alginate, applied in pharmaceutical formulations, prostheses, drug delivery, etc., to achieve the effect of reducing risk, good biocompatibility and degradability, and promoting repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

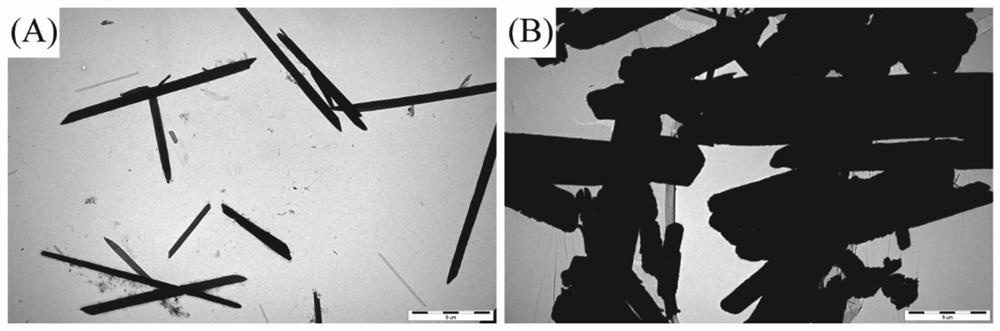

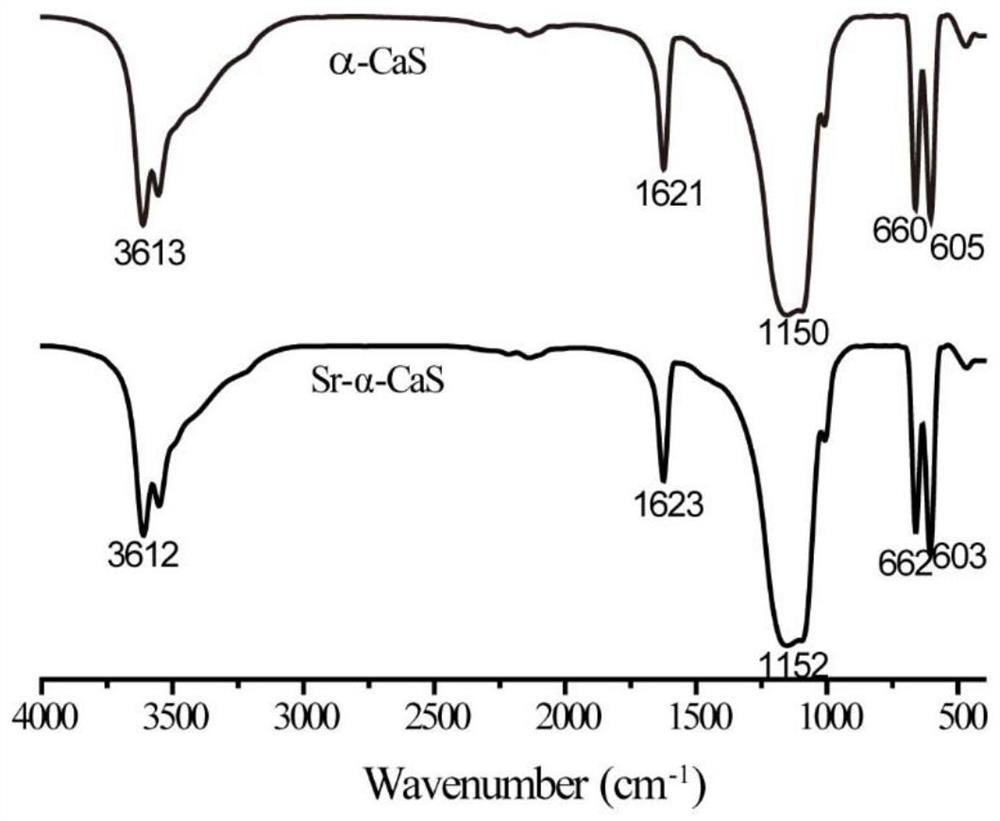

Image

Examples

Embodiment 1

[0049] The preparation method of the bone substitute material described in this embodiment comprises the following steps:

[0050] (1) Preparation of strontium-doped calcium sulfate hemihydrate:

[0051] Weigh 0.05mol of Sr(OH) 2 ·8H 2 O and 0.45mol of Ca(OH) 2 Put it into a beaker, add an appropriate amount of deionized water and stir until uniform to obtain a suspension; take 0.5mol concentrated sulfuric acid and dilute to 50ml, and slowly add it dropwise into the uniformly stirred suspension at 30°C while stirring; Before the sulfuric acid is dropped, the suspension should maintain a pH ≥ 8.5; after the sulfuric acid is dropped, the suspension is stirred for 3 hours, and then filtered while it is hot, and the obtained filter residue is dried in an oven at 50°C for 4 hours, and then the obtained Sr -CaSO 4 2H 2 O is ground into 200 mesh powder, and then according to Sr-CaSO 4 2H 2 The weight ratio of O and deionized water is 0.15. Add deionized water for mixing, and r...

Embodiment 2

[0058] The preparation method of the bone substitute material described in this embodiment comprises the following steps:

[0059] (1) Preparation of strontium-doped calcium sulfate hemihydrate:

[0060] Weigh 0.05mol of Sr(OH) 2 ·8H 2 O and 0.95mol of Ca(OH) 2 Put it into a beaker, add an appropriate amount of deionized water and stir until uniform to obtain a suspension; dilute 1 mol of concentrated sulfuric acid to 50ml, and slowly add it dropwise into the stirred suspension at 28°C while stirring; Before the sulfuric acid is dropped, the suspension should keep pH ≥ 8.5; after the sulfuric acid is dropped, the suspension is stirred for 4 hours, and then filtered while it is hot, and the obtained filter residue is dried in an oven at 50°C for 4 hours, and then the obtained Sr- CaSO 4 2H 2 O was ground into 200 mesh powder, and then according to Sr-CaSO 4 2H 2 The weight ratio of O and deionized water is 0.15. Add deionized water for mixing, and react in an oven or muf...

Embodiment 3

[0067] The preparation method of the bone substitute material described in this embodiment comprises the following steps:

[0068] (1) Preparation of strontium-doped calcium sulfate hemihydrate:

[0069] Weigh 0.05mol of Sr(OH) 2 ·8H 2 O and 0.45mol of Ca(OH) 2Put it into a beaker, add an appropriate amount of deionized water and stir until uniform to obtain a suspension; take 0.5mol concentrated sulfuric acid and dilute to 50ml, and slowly add it dropwise to the uniformly stirred suspension at 32°C while stirring; Before the sulfuric acid is dropped, the suspension should maintain a pH ≥ 8.5; after the sulfuric acid is dropped, the suspension is stirred for 2 hours, and then filtered while it is hot, and the obtained filter residue is dried in an oven at 50°C for 4 hours, and then the obtained Sr -CaSO 4 2H 2 O is ground into 200 mesh powder, and then according to Sr-CaSO 4 2H 2 The weight ratio of O and deionized water is 0.15. Add deionized water for mixing, and reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com