Sticky controllable adhesive tape and application method thereof

An adhesive tape and sticky technology, applied in the field of controllable adhesive tape, which can solve the problems of small, a few millimeters or tenths of a millimeter, failure to pick up, and the tape is not suitable for use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

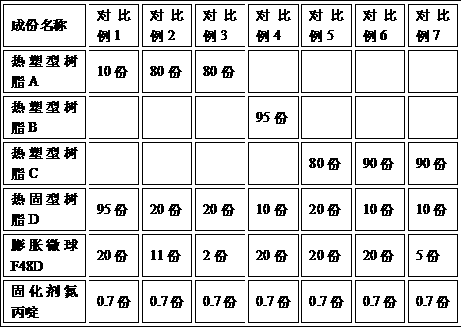

Examples

preparation example Construction

[0033] For the synthetic method of thermosetting resin, comprise the following steps:

[0034] ① After mixing 50 parts of butyl acrylate, 15 parts of acrylic acid and 35 parts of methyl methacrylate, take 25% of the mixed monomer, 0.1 part of azobisisobutyronitrile and 25 parts of ethyl acetate into the reaction kettle , heated to 85°C for 20 minutes;

[0035] ② Mix the remaining monomer with 1.25 parts of azobisisobutyrocyanide and 35 parts of ethyl acetate and drop them into the reaction kettle within 4 hours;

[0036] ③ After continuing to react for 150 minutes, add 148 parts of toluene and 23 parts of ethyl acetate to dilute while cooling, and the final solid content is about 30%.

[0037] And a kind of application method of viscous controllable adhesive tape on ceramic lamination cutting, comprises the following steps:

[0038] ① Lamination: Fix a viscous controllable tape on the heating platform, set the temperature of the heating platform at 70-95°C, then cover the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com