Aqueous anti-corrosion anti-aging wave-absorbing coating and preparation method thereof

A wave-absorbing coating and wave-absorbing layer technology, applied in the field of wave-absorbing materials, can solve the problems of limited service life of the coating, easy cracking of the coating, poor corrosion resistance, etc., and achieve good solvent resistance, excellent aging resistance, The effect of high powder content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

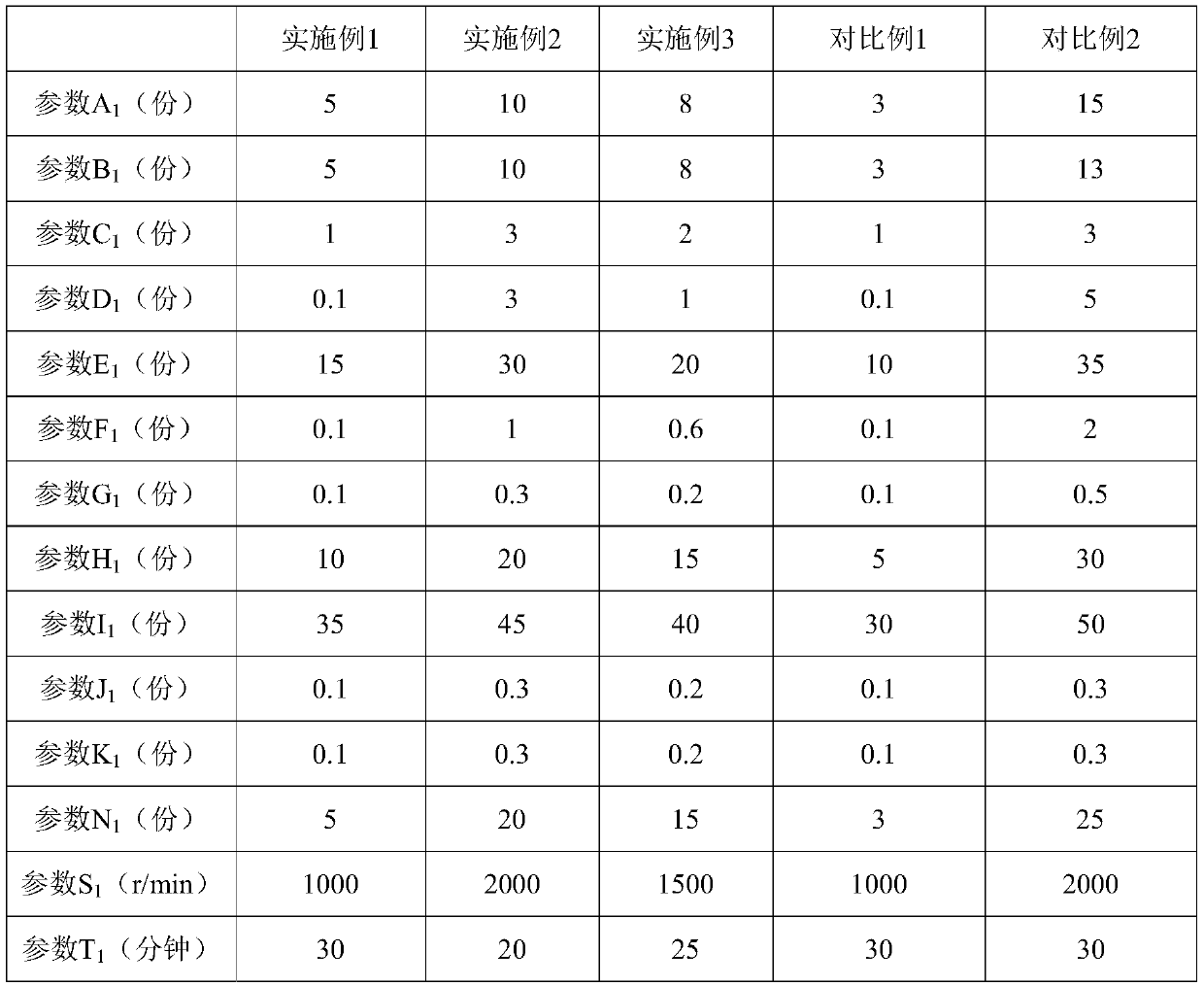

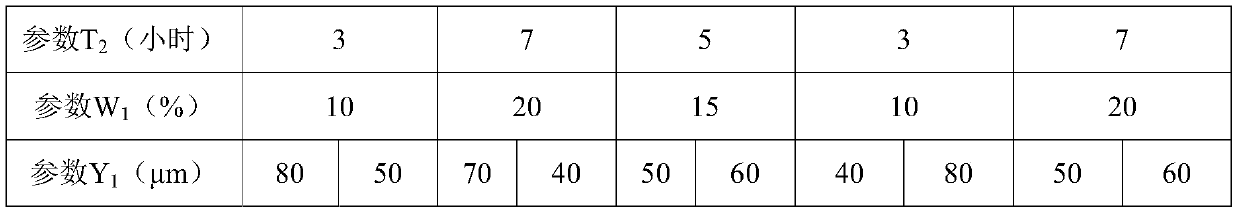

[0080] The different values of each parameter in Embodiment 1-3 constitute different specific embodiments, for example: parameter A 1 , B 1 、C 1 、A 2 , B 2 、C 2 、A 3 ,E 3 、H 3 etc., as shown in Table 1, Table 2 and Table 3.

[0081] A water-based anti-corrosion and aging-resistant wave-absorbing coating comprises a two-component water-based epoxy primer layer, a two-component water-based polyurethane wave-absorbing layer and a two-component water-based polyurethane topcoat layer arranged in sequence.

[0082] The preparation method of this wave-absorbing coating comprises the following steps:

[0083] (1) The preparation of two-component water-based epoxy primer layer, the values of each parameter are as shown in Table 1:

[0084] ① In parts by weight, A 1 carbon black, B 1 part titanium dioxide, C 1 parts strontium chrome yellow, D 1 Molybdenum zinc phosphate, E 1 Parts Precipitated Barium Sulfate, F 1 Parts 695W, G 1 Parts BYK012 and H 1 Parts of deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com