Photocurable waterborne hyperbranched resin and preparation method thereof

A hyperbranched resin and light-curing technology, which is applied in biocide-containing paints, anti-fouling/underwater coatings, coatings, etc., can solve the problems of poor storage stability of light-cured water-based resins, and achieve excellent water resistance and storage stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

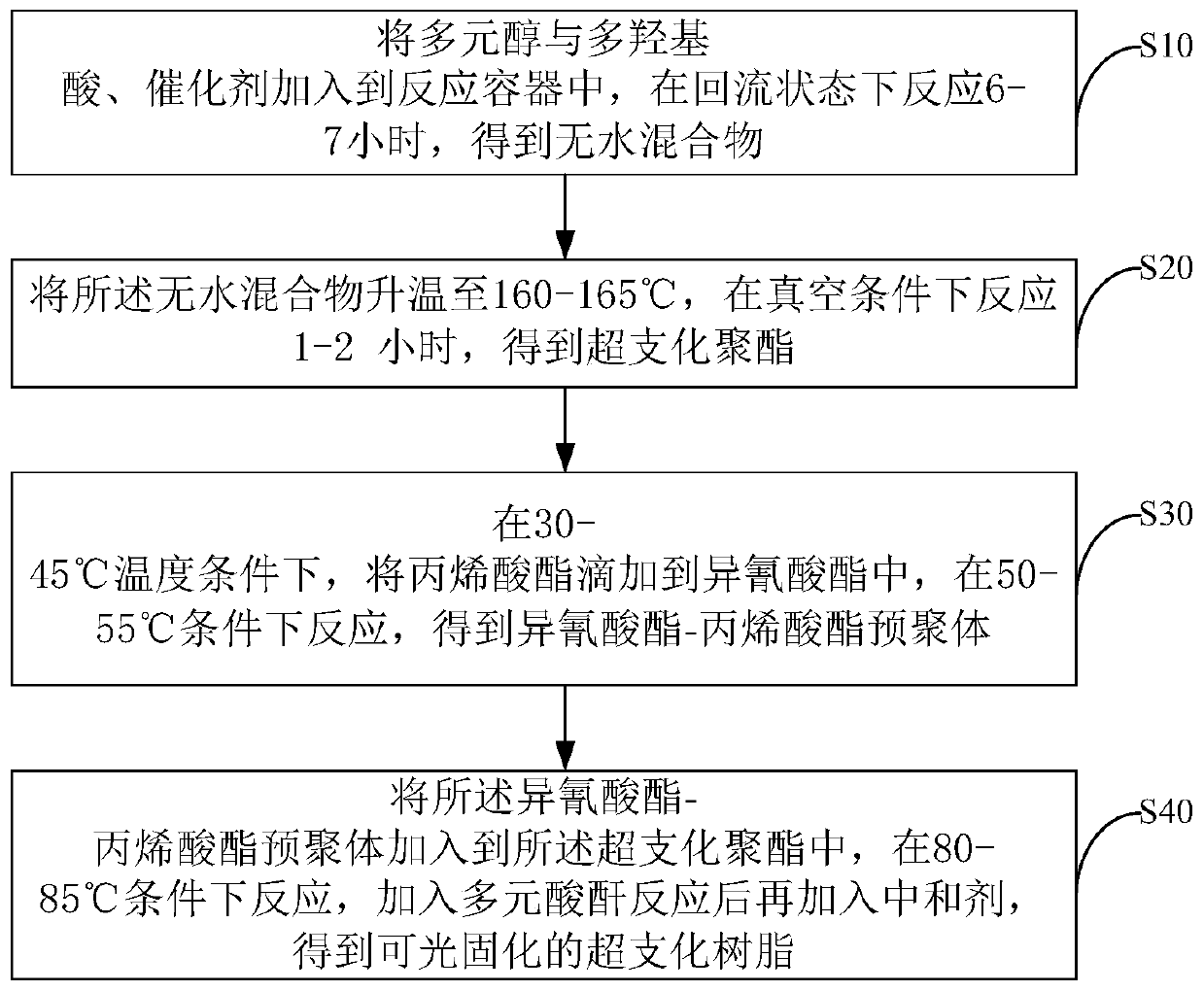

Method used

Image

Examples

Embodiment approach

[0035] As an embodiment, the polyol is used as the core molecule. Generally, low molecular weight polyol is selected as the core molecule. The core molecule can be synthesized with a polyhydroxy acid to form a macromolecular high-functional polyol. For example, the main polyol includes but is not limited to trimethylol One or more of propane, pentaerythritol, glycerol, trihydroxyethylethane, sorbitol, polyether triol and polyester triol.

[0036] As an embodiment, the isocyanate may be one or more of aliphatic isocyanate, alicyclic isocyanate and aromatic diisocyanate. Aliphatic isocyanates are preferred. It is beneficial to the stability of waterborne hyperbranched resin.

[0037] As an embodiment, the acrylate is hydroxyethyl acrylate, hydroxyethyl methacrylate, hydroxypropyl acrylate, hydroxypropyl methacrylate, butylene glycol acrylate, hexanediol acrylate, trimethylol One or more of base diacrylate and pentaerythritol triacrylate.

[0038] As an embodiment, the neutral...

Embodiment 1

[0062] Step (1) Add 14g trimethylolpropane, 200g dimethylolpropionic acid, 0.8g p-methylolpropane to a 1000ml four-neck flask equipped with a stirrer, condenser, water separator, and thermometer under nitrogen protection. Benzenesulfonic acid, 150g of xylene is heated up to 135°C to start the reaction. When no more water distills out of the water separator, the temperature is raised to 160°C, and the reaction is vacuumed for 1 hour to remove the xylene. The acid value of the system is 18mgKOH / g, and you can get hyperbranched polyester.

[0063] Step (2) Add 190g of IPDI into another three-necked flask equipped with a stirrer and a thermometer, add 0.1g of MEHQ, rise to 45°C, add 104g of hydroxyethyl acrylate dropwise, and react at 50°C until the NCO is 12.5% , to obtain an isocyanate-acrylate prepolymer.

[0064] Step (3) Add the isocyanate-acrylate prepolymer obtained in step (2) to the hyperbranched polyester obtained in step (1), and raise the temperature to 80° C. to reac...

Embodiment 2

[0069] Step (1) In a 1000ml four-necked flask equipped with a stirrer, a condenser, a water separator, and a thermometer, add 14g of pentaerythritol, 160g of dimethylolpropionic acid, 1g of p-toluenesulfonic acid, and 150g of Raise the temperature of xylene to 145°C to start the reaction. When no more water distills out of the water separator, raise the temperature to 165°C, and perform a vacuum reaction for 2 hours to remove xylene. The acid value of the system is 10mgKOH / g, and the hyperbranched polyester can be obtained. .

[0070] Step (2) Add 134g HDI into another three-necked flask equipped with a stirrer and a thermometer, add 0.12g MEHQ, raise to 45°C, add 104g hydroxyethyl methacrylate dropwise, and react at 55°C until NCO is 14.1%, an isocyanate-acrylate prepolymer was obtained.

[0071] Step (3) Add the isocyanate-acrylate prepolymer obtained in step (2) to the hyperbranched polyester obtained in step (1), and the temperature rises to 85° C. until the NCO in the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com