A low-temperature battery formation process

A low-temperature battery and process technology, applied in the direction of lead-acid batteries, lead-acid battery construction, sustainable manufacturing/processing, etc., can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

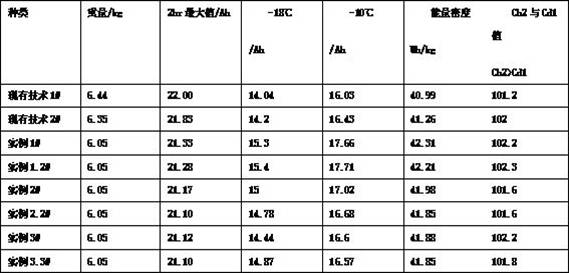

Examples

Embodiment 1

[0065] Before the battery is formed, it is necessary to make a semi-finished battery for backup: the positive and negative plates produced by lead powder ball milling, grid casting, lead powder paste, lead powder coating, and plate curing are separated by AGM glass fiber cotton. The capacity is assembled into a single lead-acid battery pack, and the positive and negative poles are connected in parallel. The cells are connected in series, and then sealed by the middle cover to obtain a semi-finished battery for backup.

[0066] Configure the masterbatch for backup:

[0067] Raw materials: select industrial grade silica powder produced by gas phase method, with an average particle size of 0.17µm, a silica content of over 99.89%, and a density of 50g / L after drying at 105°C for 2 hours, which is in a hydrophobic state;

[0068] Preparation equipment: the speed is adjustable from 4000 to 5000r / min, and the volume is 800kg;

[0069] Configuration method: Add 600kg of deionized wa...

Embodiment 2

[0103] Before the battery is formed, it is necessary to make a semi-finished battery for backup: the positive and negative plates produced by lead powder ball milling, grid casting, lead powder paste, lead powder coating, and plate curing are separated by AGM glass fiber cotton. The capacity is assembled into a single lead-acid battery pack, and the positive and negative poles are connected in parallel. The cells are connected in series, and then sealed by the middle cover to obtain a semi-finished battery for backup.

[0104] Configure the masterbatch for backup;

[0105] Raw materials: choose industrial grade silica powder produced by gas phase method, with an average particle size of 0.13µm, a silica content of 99.5%, and a density of 50g / L after drying at 105°C for 2 hours, which is in a hydrophobic state;

[0106] Preparation equipment: the speed is 4000 to 5000r / min, and the volume is 800kg;

[0107] Configuration method: add 600kg deionized water into the equipment, t...

Embodiment 3

[0142] Before the battery is formed, it is necessary to make a semi-finished battery for backup: the positive and negative plates produced by lead powder ball milling, grid casting, lead powder paste, lead powder coating, and plate curing are separated by AGM glass fiber cotton. The capacity is assembled into a single lead-acid battery pack, and the positive and negative poles are connected in parallel. The cells are connected in series, and then sealed by the middle cover to obtain a semi-finished battery for backup.

[0143] Configure the masterbatch for backup;

[0144] Raw materials: select industrial grade silica powder produced by gas phase method, with an average particle size of 0.2µm and a silica content of 99.99%, after drying at 105°C for 2 hours, the density is 50g / L, which is in a hydrophobic state;

[0145] Preparation equipment: the speed is 4000 to 5000r / min, and the volume is 800kg;

[0146] Configuration method: add 600kg deionized water into the equipment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com