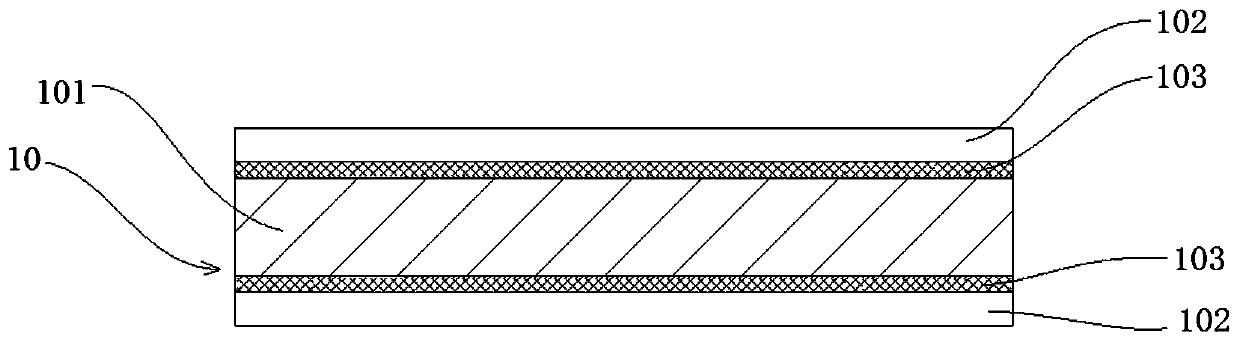

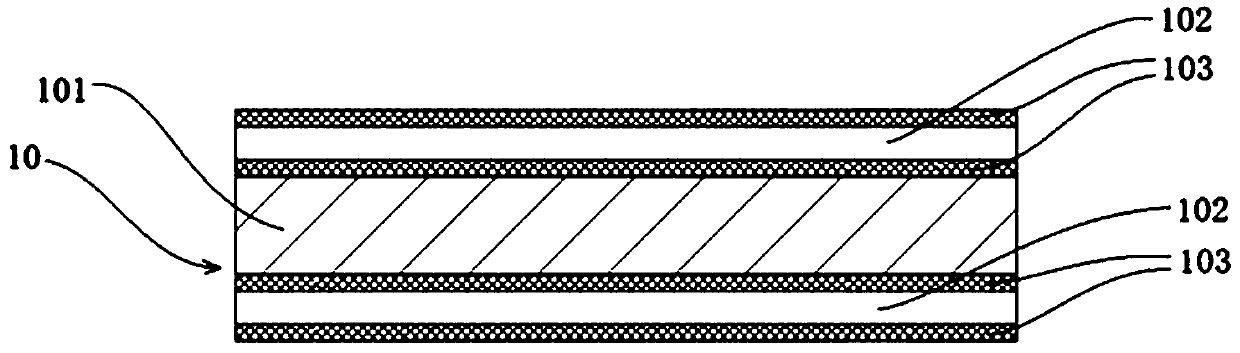

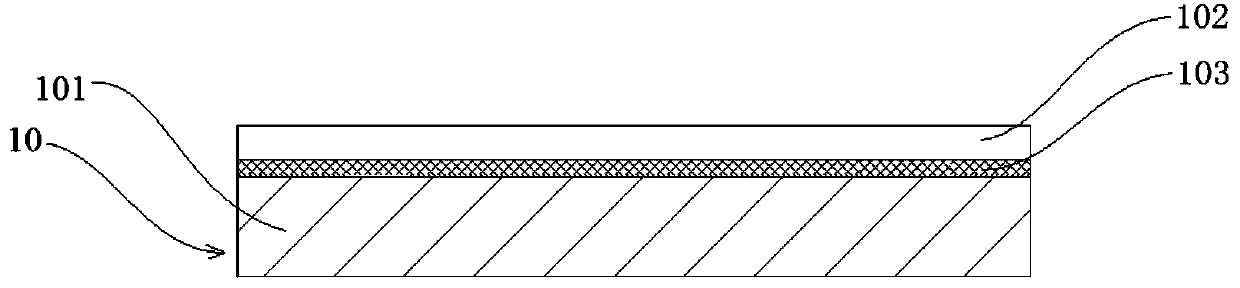

Electrode pole sheet and electrochemical device

A technology of electrode pole pieces and electrode active materials, which is applied in the battery field and can solve problems such as processing performance, safety performance and electrical performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0151] 1. Preparation of current collector without protective layer:

[0152] Select a support layer with a certain thickness, and form a conductive layer with a certain thickness on its surface by means of vacuum evaporation, mechanical rolling or bonding.

[0153] in,

[0154] (1) The formation conditions of the vacuum evaporation method are as follows: the support layer that has been cleaned on the surface is placed in a vacuum coating room, and the high-purity metal wire in the metal evaporation room is melted and evaporated at a high temperature of 1600 ° C to 2000 ° C. The evaporated metal After passing through the cooling system in the vacuum plating chamber, it is finally deposited on the surface of the support layer to form a conductive layer.

[0155] (2) The formation conditions of the mechanical rolling method are as follows: place the foil of the conductive layer material in a mechanical roll, roll it to a predetermined thickness by applying a pressure of 20t to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single side thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Single side thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com