High-temperature-resistant flame-retardant powder paint and production method thereof

A flame-retardant powder and powder coating technology, applied in powder coatings, fire-resistant coatings, epoxy resin coatings, etc., can solve the problems of easy ignition and combustion, no flame retardancy, personal safety threats, etc., to achieve excellent thermal oxidation Stability and electrical insulation, excellent heat resistance and UV resistance, effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

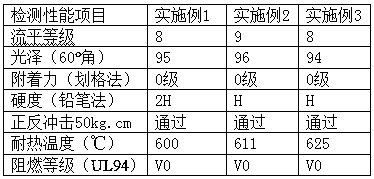

Examples

Embodiment 1

[0036] A high-temperature-resistant flame-retardant powder coating, prepared from the following raw materials in parts by weight: 30 parts of silicone resin, 30 parts of epoxy resin, 3.4 parts of modified dicyandiamide, 0.2 parts of dimethylimidazole, and 10 parts of silicon micropowder 10 parts, 10 parts of mica powder, 0.3 parts of sanding agent, 30 parts of flame retardant, 1.2 parts of carbon black.

[0037] The silicone resin was purchased from Guangzhou Rongda Chemical Co., Ltd.

[0038] The epoxy resin is bisphenol A type epoxy resin.

[0039] The modified dicyandiamide is furfural modified dicyandiamide.

[0040] The dimethylimidazole was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0041] The microsilica powder was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0042] The mica powder is superfine muscovite powder, purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0043] The sand texture a...

Embodiment 2

[0054] A high-temperature-resistant flame-retardant powder coating prepared from the following raw materials in parts by weight: 45 parts of silicone resin, 45 parts of epoxy resin, 5.1 parts of modified dicyandiamide, 0.3 parts of dimethylimidazole, and 15 parts of silicon micropowder parts, 15 parts of mica powder, 0.4 parts of sanding agent, 45 parts of flame retardant, and 1.8 parts of carbon black.

[0055] The silicone resin was purchased from Guangzhou Rongda Chemical Co., Ltd.

[0056] The epoxy resin is a mixture of bisphenol A type epoxy resin and novolak epoxy resin.

[0057] The modified dicyandiamide is furfural modified dicyandiamide.

[0058] The dimethylimidazole was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0059] The microsilica powder was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0060] The mica powder is superfine muscovite powder, purchased from Guangzhou Shengqi Polymer Material Technology C...

Embodiment 3

[0072] A high-temperature-resistant flame-retardant powder coating prepared from the following raw materials in parts by weight: 60 parts of silicone resin, 60 parts of epoxy resin, 6.8 parts of modified dicyandiamide, 0.4 part of dimethylimidazole, and 20 parts of silicon micropowder 20 parts, 20 parts of mica powder, 0.6 parts of sanding agent, 60 parts of flame retardant, 2.4 parts of carbon black.

[0073] The silicone resin was purchased from Guangzhou Rongda Chemical Co., Ltd.

[0074] The epoxy resin is novolac epoxy resin.

[0075] The modified dicyandiamide is furfural modified dicyandiamide.

[0076] The dimethylimidazole was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0077] The microsilica powder was purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0078] The mica powder is superfine muscovite powder, purchased from Guangzhou Shengqi Polymer Material Technology Co., Ltd.

[0079] The sand texture agent was pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com