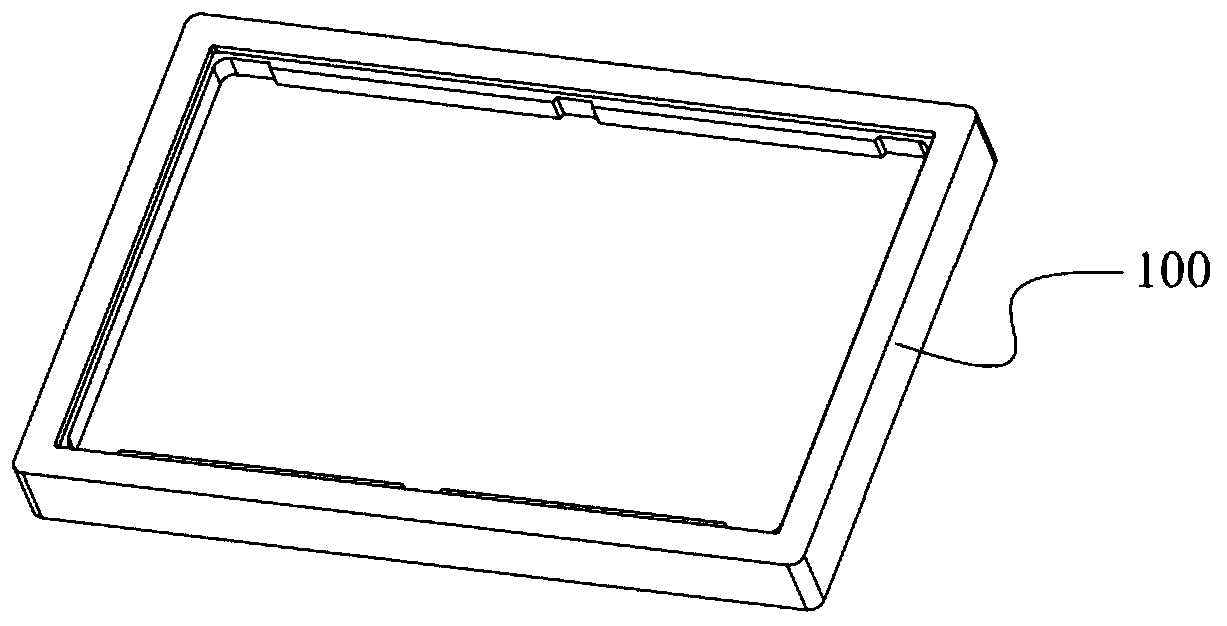

Foam box

A foam box and foaming ratio technology, applied in the field of foam boxes, can solve problems such as poor impact resistance, raw material limitations, and poor anti-collision performance, so as to improve stiffness and strength, increase recycling times, and enhance impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

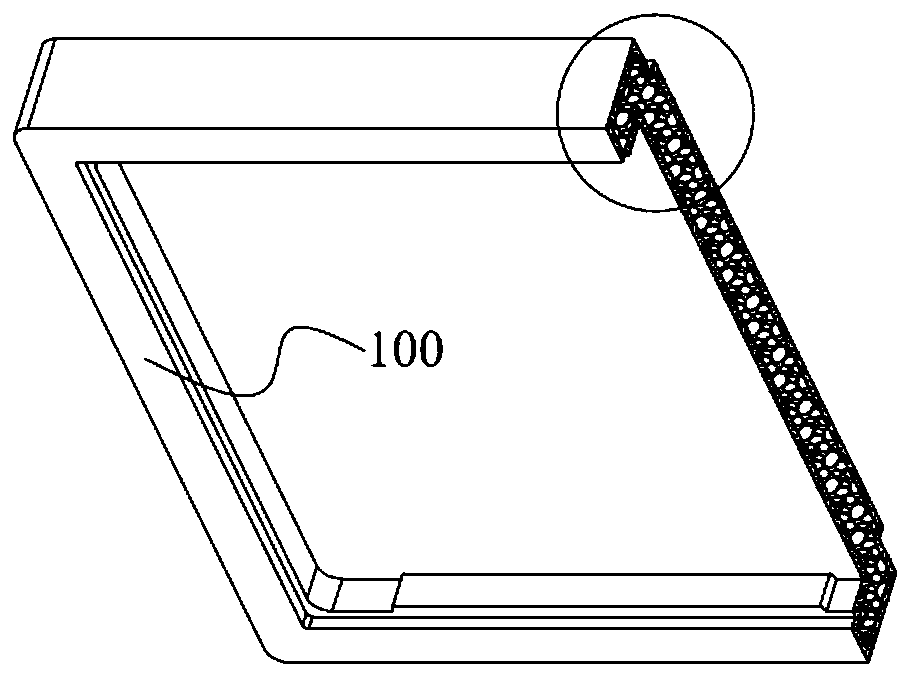

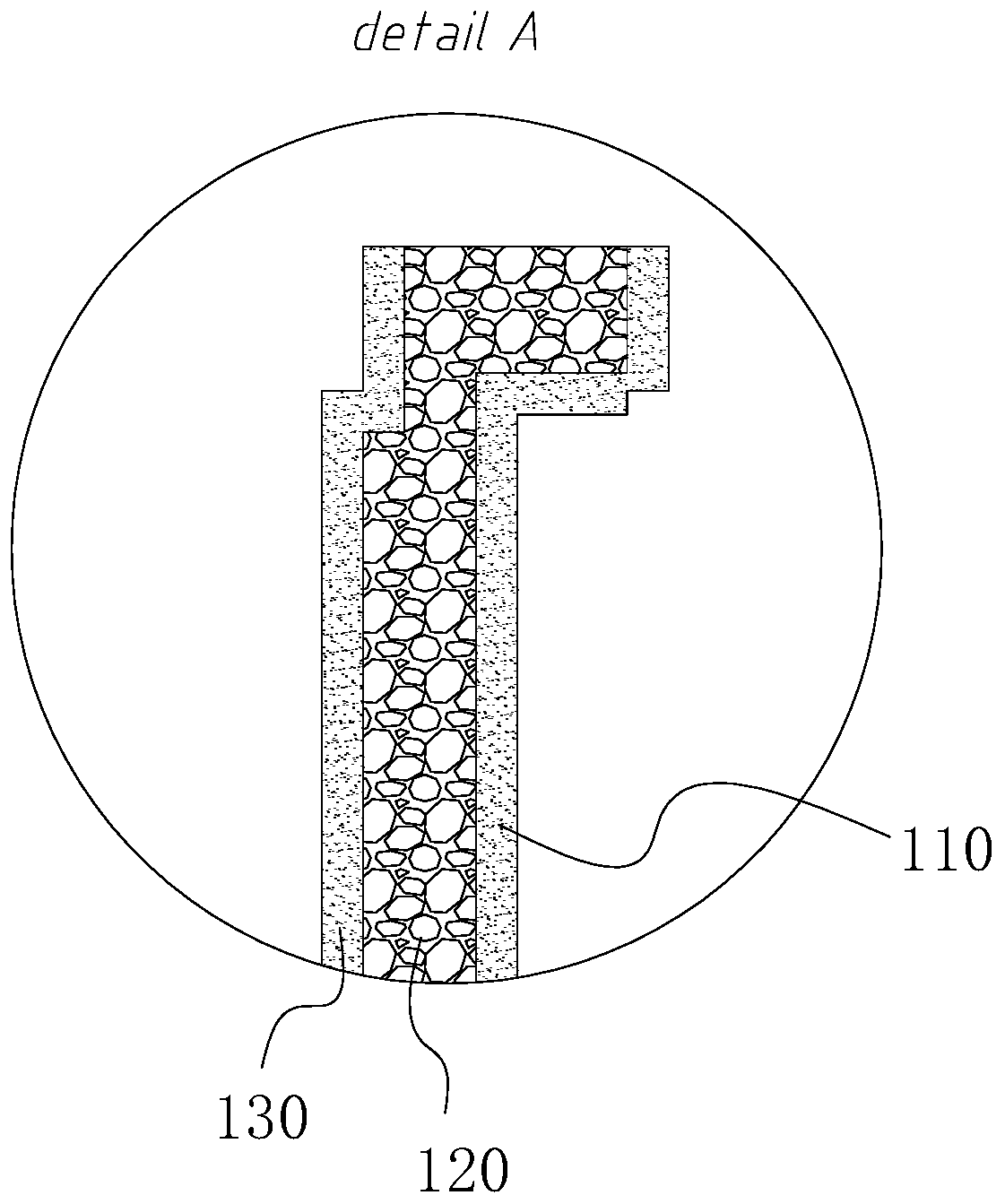

[0032] The first embodiment: as Figure 4 As shown, the thickness of the outer layer 110 is 15%-25% of the total thickness, the material is EPS, and the expansion ratio is 12-18 times (preferably 15 times). The thickness of the middle layer 120 is 55%-65% of the total thickness, the material is EPS, and the expansion ratio is 35-45 times (preferably 40 times). The thickness of the inner layer 130 is 15%-25% of the total thickness, the material is EPS, and the expansion ratio is 12-18 times (preferably 15 times).

[0033] The inner layer 130 and the outer layer 110 have a low expansion ratio (high density), less chance of chipping, and good strength; the middle layer 120 has a high expansion ratio (low density), and the packaging box 100 is light in weight and low in cost.

no. 2 example

[0034] The second embodiment: as Figure 5 As shown, the thickness of the inner layer 110 is 15%-25% of the total thickness, the material is EPP, and the expansion ratio is 25-35 times (preferably 30 times); the thickness of the middle layer 120 is 55%-65% of the total thickness. %, the material is EPS, and the expansion rate is 35-45 times (preferably 40 times); the thickness of the outer layer 130 is 15%-25% of the total thickness, and the material is EPO, and the expansion rate is 20-30 times (preferably 40 times); is 25 times).

[0035] The material of the inner layer 130 and the outer layer 110 is not easy to chip, and has good impact resistance; the material of the middle layer 120 is cheap, which can reduce the overall cost; the material of the inner layer 130 and the outer layer 110 has good cushioning performance, and the rigidity of the middle layer 120 Better, the overall performance is better than a single material.

no. 3 example

[0036] The third embodiment: as Figure 6 As shown, the thickness of the inner layer 110 is 15%-25% of the total thickness, the material is EPP, and the expansion ratio is 25-35 times (preferably 30 times); the thickness of the middle layer 120 is 40%-50% of the total thickness. %, the material is EPS, and the expansion rate is 35-45 times (preferably 40 times); the thickness of the outer layer 130 is 30%-40% of the total thickness, the material is EPO, and the expansion rate is 12-18 times (preferably 40 times); is 15 times).

[0037] The material of the inner layer 110 and the outer layer 130 is not easy to chip, and has good impact resistance; the material of the middle layer 120 is cheap, which can reduce the overall cost; the material of the inner layer 110 and the outer layer 130 has better cushioning properties, and the middle layer has better rigidity , the overall performance is better than that of a single material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com