TiAl-based high-temperature resistant self-lubricating composite material and preparation method thereof

A composite material, self-lubricating technology, applied in the field of composite materials, can solve the problems of no high temperature resistance, limited application, poor lubrication performance, etc., and achieve the effect of improving brittle defects and high self-lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The above Ti 3 AlC 2 -Preparation method of TiC-TiAl based high temperature resistant self-lubricating composite material, including:

[0038] Step S1, preparing TiAl mixed powder:

[0039] In an argon atmosphere, the Ti, Al, and Cr powders are ball-milled and mixed uniformly to obtain a TiAl mixed powder.

[0040] In this step, in the process of preparing TiAl mixed powder, instead of simply mixing the three powders of Ti, Al, and Cr, ball milling and mixing are performed, and mechanical alloying is used during the mixing process to make the The three metal elements interdiffused to form a more active alloy matrix.

[0041] Further, when ball milling and mixing, the ball-to-material ratio is 2-10:1, the rotation speed is 200-400r / min, the ball milling time is 3-10h, and the forward and reverse runs alternately every 20-40min. Using this ball milling process, the obtained TiAl mixed powder has higher activity.

[0042] Preferably, the particle size of the raw mater...

Embodiment 1

[0067] This embodiment provides a Ti 3 AlC 2 -TiC-TiAl based high temperature resistant self-lubricating composite material, the preparation method of which is:

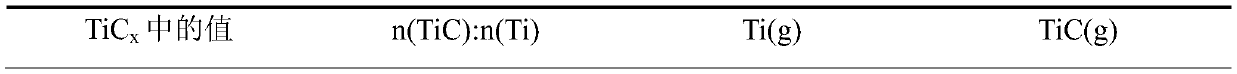

[0068] After adding a dispersant to the raw material powder composed of titanium carbide powder and titanium powder with a molar ratio of 4:6, carry out ball milling. The dispersant is analytically pure ≥99.7% industrial ethanol, and 0.6mL of dispersant is added to every 10g of powder; Both 5mm and 8mm WC carbide balls are used in the ball milling process, the mass ratio of large and small balls is 7:3; the mass ratio of balls and materials is 12:1, the speed is 350r / min, the ball milling is 20h, and each revolution is 60min. Shut down for 20 minutes to dissipate heat and produce TiC finer than 150nm 0.4 .

[0069] Then 70-mesh Ti, 80-mesh Al, and 70-mesh Cr powders were ball-milled and mixed evenly. The mixing process was carried out in an argon atmosphere. The ball-milling process used both 5mm and 8mm WC cement...

Embodiment 2

[0072] This embodiment provides a Ti 3 AlC 2 -TiC-TiAl based high temperature resistant self-lubricating composite material, the preparation method of which is:

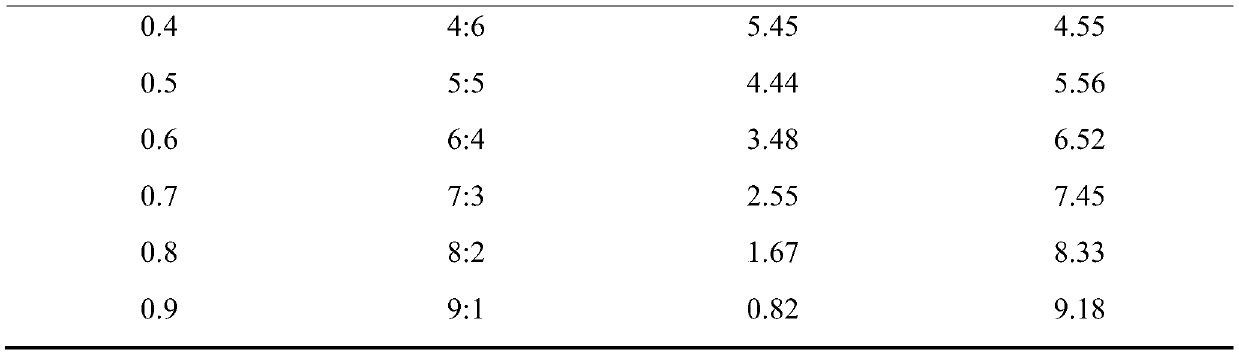

[0073] After adding a dispersant to the raw material powder composed of titanium carbide powder and titanium powder with a molar ratio of 8:2, carry out ball milling. The dispersant is analytically pure ≥99.7% industrial ethanol, and 0.6mL of dispersant is added to every 10g of powder; Both 5mm and 8mm WC cemented carbide balls are used in the ball milling process, the mass ratio of large and small balls is 7:3; the mass ratio of balls and materials is 10:1, the speed is 600r / min, the ball mill is 70h, and each revolution is 60min. Shut down for 20 minutes to dissipate heat and produce TiC0.8 finer than 150nm.

[0074] Then 140-mesh Ti, 170-mesh Al, and 200-mesh Cr powder were ball-milled and mixed evenly. The mixing process was carried out in an argon atmosphere. The ball-milling process used both 5mm and 8mm WC c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com