Single-row reinforcement sheet with fiber concrete on frames and common concrete in middle and manufacturing method

A technology of fiber-reinforced concrete and ordinary concrete, which is applied to building materials, building components, buildings, etc., can solve the problems of low bearing capacity, low frame strength, easy to be damaged, and high cost, so as to increase the bearing capacity, reduce the working intensity of workers, The effect of controlling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

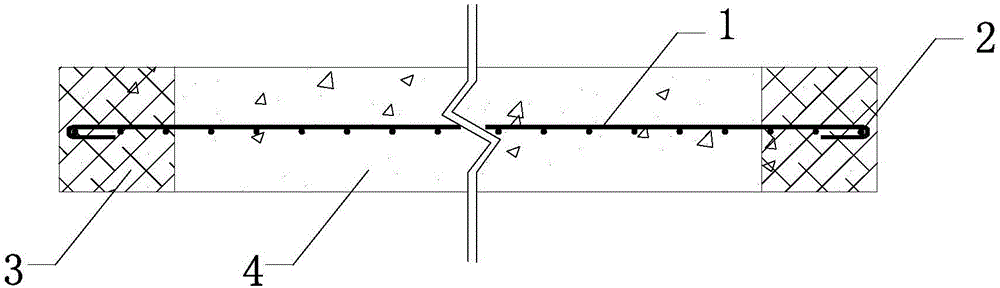

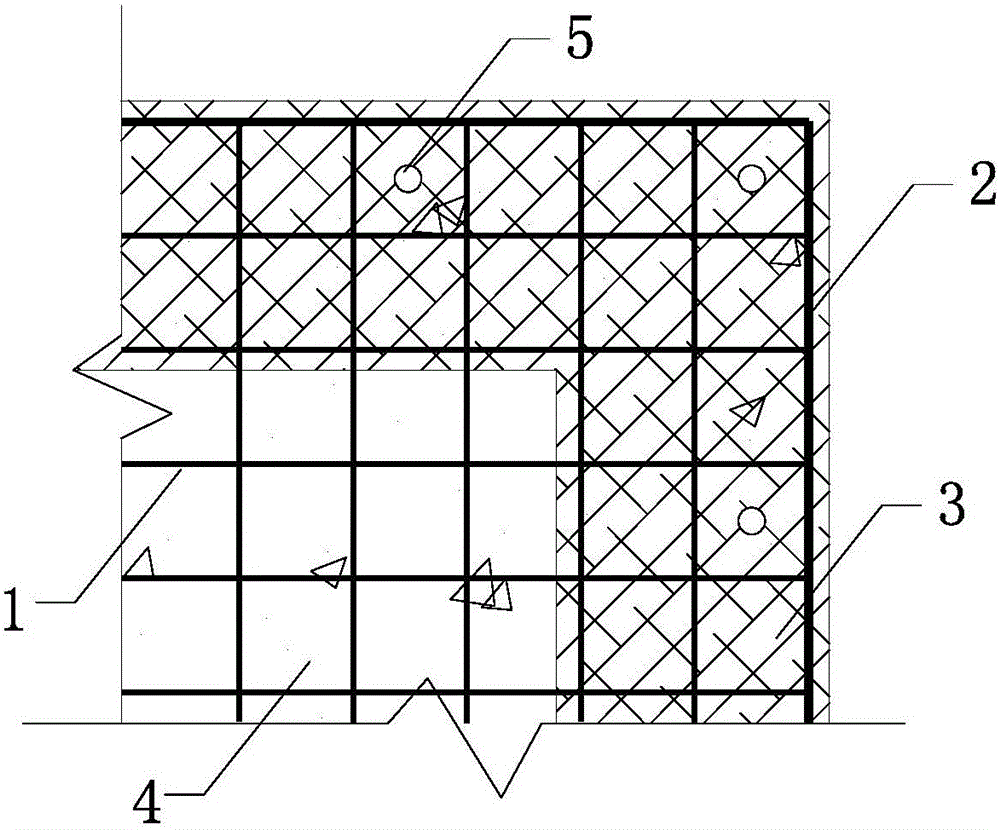

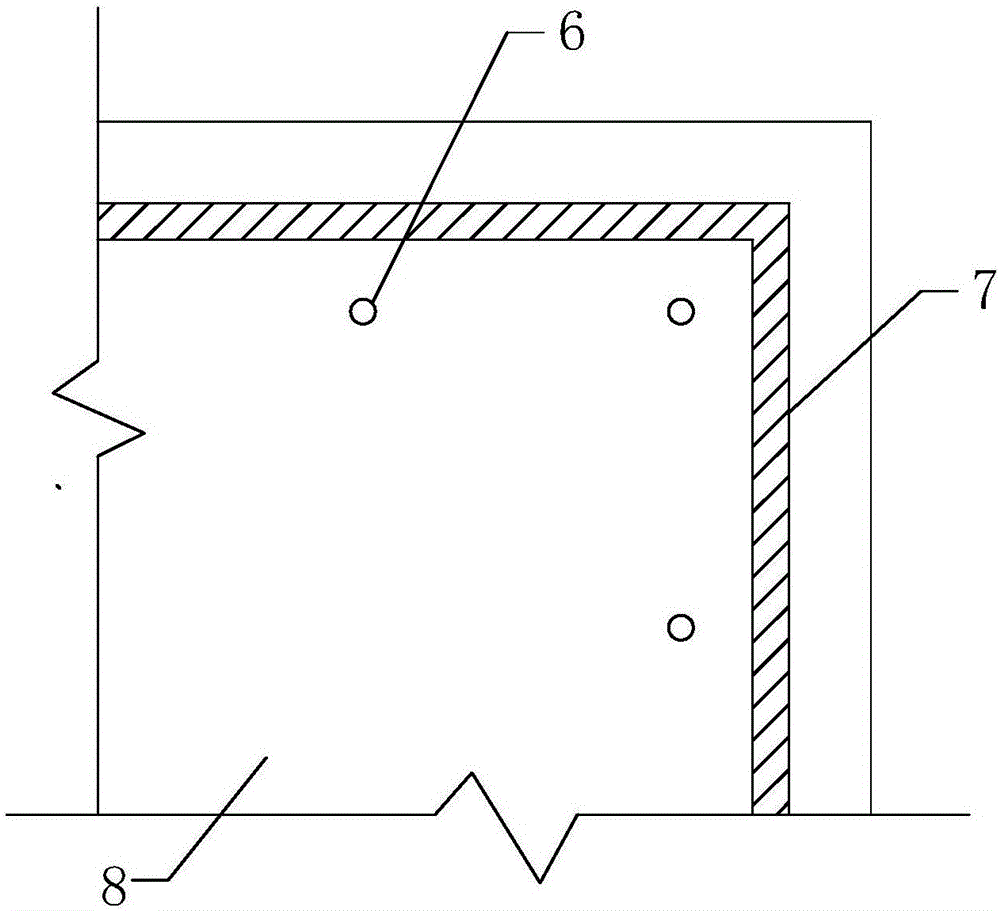

[0032] as attached figure 1 And attached figure 2 , an ordinary concrete single-row reinforced thin slab in the middle of frame fiber concrete, including internal orthogonal steel mesh (1), end reinforcement (2), fiber concrete (3), ordinary concrete (4), and reserved at the end of the thin slab Bolt holes (5); bend the protruding part of the end steel wire of the diameter Φ2 internal orthogonal steel mesh (1) by 180°, and arrange the end steel bars (2) in the bending arc to form a complete concrete sheet with built-in orthogonal steel bars For the mesh sheet, fiber concrete (3) is poured around the orthogonal steel mesh sheet, and ordinary concrete (4) is poured inside the orthogonal steel mesh sheet. image 3 It is the top view of the ordinary concrete single-row reinforced thin slab pouring formw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com