Thermosetting hydrocarbon polymer composition, and prepreg and thermosetting copper-clad plate prepared therefrom

A hydrocarbon polymer and prepreg technology, applied in the field of communication materials, can solve the problems of poor uniformity of thermal expansion coefficient of dielectric properties, poor compatibility, difficulty in satisfying functional diversification and complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

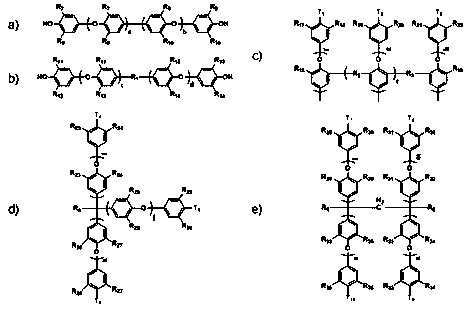

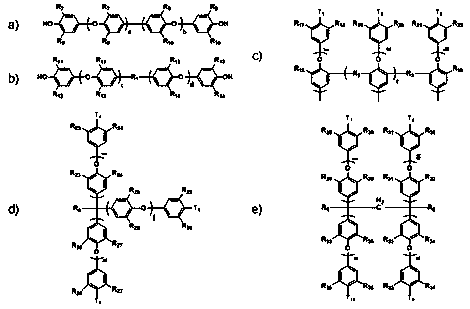

Method used

Image

Examples

Embodiment 1

[0047] Dissolve 16 parts of hydroxyl-terminated polyphenylene ether resin (Sabic SA90) and 4 parts of hydrogenated hydroxyl-terminated polyolefin resin (Krasol HLBH-P2000) in 100 parts of methyl ethyl ketone, then add 2.7 parts of 3-bromopropene and 2.5 parts Potassium tert-butoxide was stirred for 2 h under condensing reflux; then 0.03 initiator dibenzoyl peroxide (Qinfeng Chemical Industry) was added, and stirring was continued for 5 h under condensing reflux to obtain a reactive resin A solution; then, to Continue to add 65 parts of vinyl-terminated polyphenylene ether (Sabic SA9000), 35 parts of polybutadiene (Kray Willy Ricon130), 8 parts of polybutadiene-maleic anhydride copolymer ( Crayville Ricon130MA8), 12 parts polystyrene-maleic anhydride copolymer (Crayville SMA1000), 22 parts TiO 2 (Tianjin Zhongzheng Huamei Technology), 50 parts of flame retardant magnesium hydroxide (USA Yabao MAGNIFIN H-5), 20 parts of sub-flame retardant decabromodiphenylethane (Shandong Haiwa...

Embodiment 2

[0049] Dissolve 13 parts of hydroxyl-terminated polyphenylene ether resin (Sabic SA90), 4 parts of hydrogenated hydroxyl-terminated polyolefin resin (KrasolHLBH-P2000) and 3 parts of monohydroxy polyphenylene ether resin (Mn=13000) in 50 parts of methyl ethyl ketone And in the mixed solvent of 50 parts of DMF, add 2.3 parts of 3-bromopropene and 2.14 parts of potassium tert-butoxide again, at 80 o Stir at C for 2 hours; then add 0.03 initiator dibenzoyl peroxide (Qinfeng Chemical Industry), and continue stirring at 80°C for 5 hours to obtain a reactive resin A solution; then, continue to add 35 Parts of vinyl-terminated polyphenylene ether (Sabic SA9000), 30 parts of vinyl-terminated polyphenylene ether (OPE-2St, Mn=1200), 41 parts of polybutadiene (Craigville Ricon130), 8 parts Polybutadiene-maleic anhydride copolymer (Cray Willy Ricon130MA8), 6 parts polystyrene-maleic anhydride copolymer (Cray Willy SMA1000), 22 parts TiO 2 (Tianjin Zhongzheng Huamei Technology), 50 parts ...

Embodiment 3

[0051] Dissolve 16 parts of hydroxyl-terminated polyphenylene ether resin (Sabic SA90) and 4 parts of hydrogenated hydroxyl-terminated polyolefin resin (Krasol HLBH-P2000) in 100 parts of methyl ethyl ketone, then add 2.7 parts of 3-bromopropene and 2.5 parts Potassium tert-butoxide was stirred for 2 h under condensing reflux; then 0.03 initiator dibenzoyl peroxide (Qinfeng Chemical Industry) was added, and stirring was continued for 5 h under condensing reflux to obtain a reactive resin A solution; then, to Continue to add 60 parts of vinyl-terminated polyphenylene ether (Sabic SA9000), 30 parts of polybutadiene (Kray Willy Ricon130), 2.5 parts of polydiene-styrene-divinylbenzene to the reactive resin A solution Terpolymer (Crayville Ricon257), 4 parts polybutadiene-maleic anhydride copolymer (Crayville Ricon130MA8), 6 parts polystyrene-maleic anhydride copolymer (Crayville SMA1000) , 35 parts of PTFE pre-sintered material (Shandong Dongyue), 8 parts of SiO 2(Xinyi Hongrun),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com