Hollow fiber composite nanofiltration membrane based on natural polymer and preparation method thereof

A natural polymer and fiber composite technology, which is applied in the field of hollow fiber composite nanofiltration membrane and its preparation, can solve the problems of lack of binding force between the separation layer and the base membrane, difficulty in obtaining the separation layer of the nanofiltration membrane, and reduction of the performance of the nanofiltration membrane. , to achieve a good industrial production base, thin and uniform separation layer, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Dissolve 10g of natural polymer sodium alginate in 1L of water to obtain aqueous solution A; dissolve 2g of coagulant calcium chloride in 100mL of water to obtain aqueous solution B.

[0043]Immerse the outer surface of the hollow fiber polyacrylonitrile ultrafiltration support membrane treated by co-deposition surface modification of polydopamine and polyethyleneimine into the aqueous solution A (keep the interior of the hollow fiber support membrane dry), and beat the aqueous solution B by pressure into the hollow fiber and fill it.

[0044] Let the hollow fiber support membrane stand in this state for 5 minutes, then wash it several times with water, place it in saturated epichlorohydrin vapor, and cross-link it at 50°C for 5 minutes to obtain a hollow fiber composite nanomaterial based on natural polymers. The filter membrane was finally washed repeatedly with water and dried.

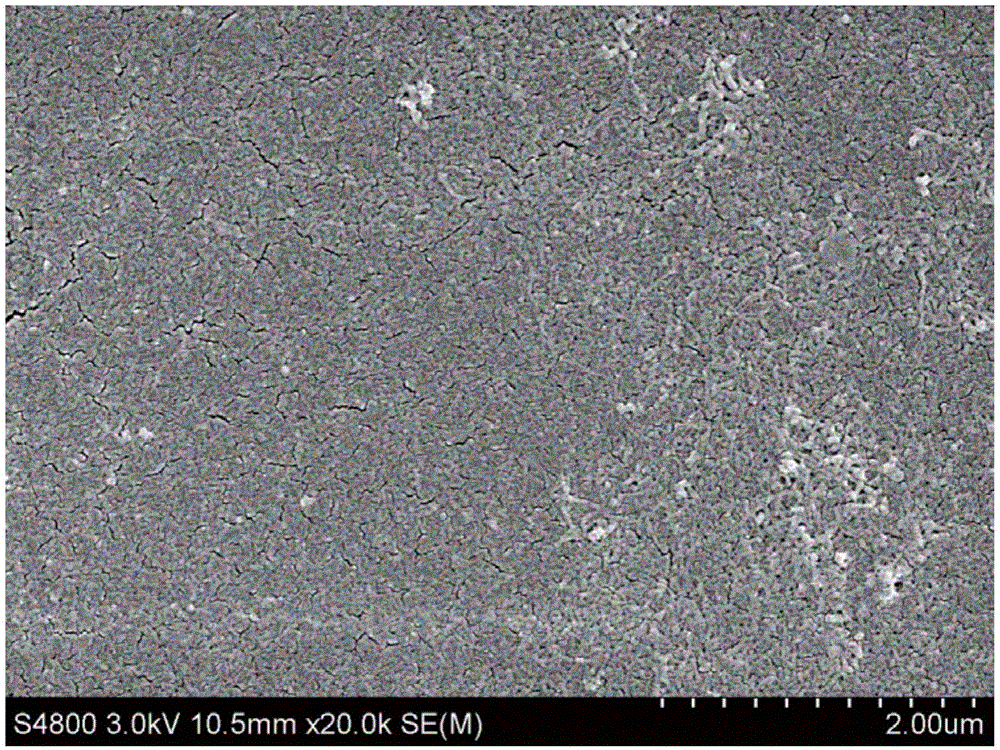

[0045] Electron micrographs of the surface of the prepared hollow fiber composite nanof...

Embodiment 2~13

[0047] Adjust the concentration of natural polymer sodium alginate and coagulant calcium chloride, the surface modification method and crosslinking reaction of the hollow fiber support membrane and other conditions are the same as in Example 1, as shown in Table 1.

Embodiment 14~17

[0055] Regulate the time that coagulant diffuses in natural macromolecular solution, and natural macromolecular sodium alginate concentration is 10g / L, and coagulant calcium chloride concentration is 2g / L, and all the other conditions are with embodiment 1, as shown in table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com