Antibacterial reverse-osmosis composite membrane as well as preparation method and application thereof

A reverse osmosis composite membrane and technology of reverse osmosis membrane, which are applied to antibacterial reverse osmosis composite membrane, its preparation and application fields, can solve the problems of high equipment requirements, long time consumption, complicated process, etc., and achieve good antibacterial effect and good dispersibility. , good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1 prepares antibacterial reverse osmosis composite membrane according to the following steps:

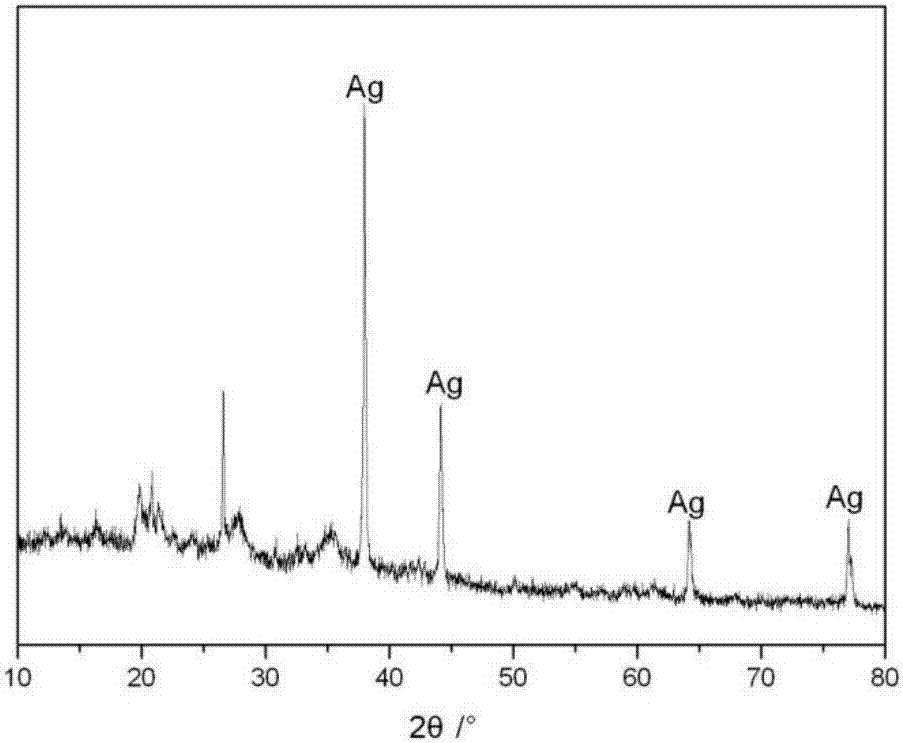

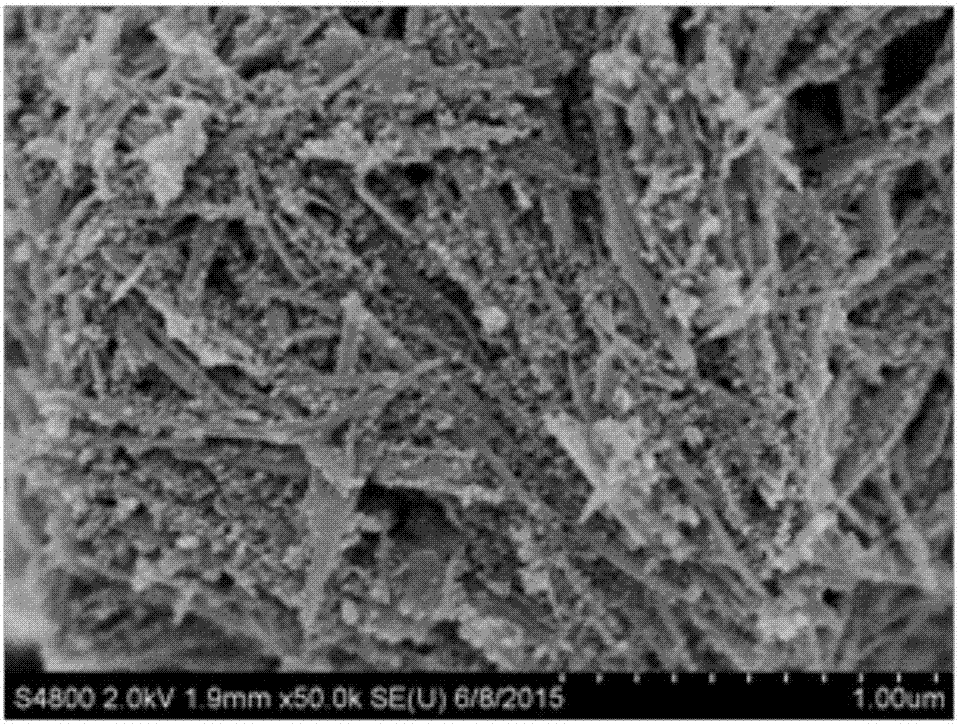

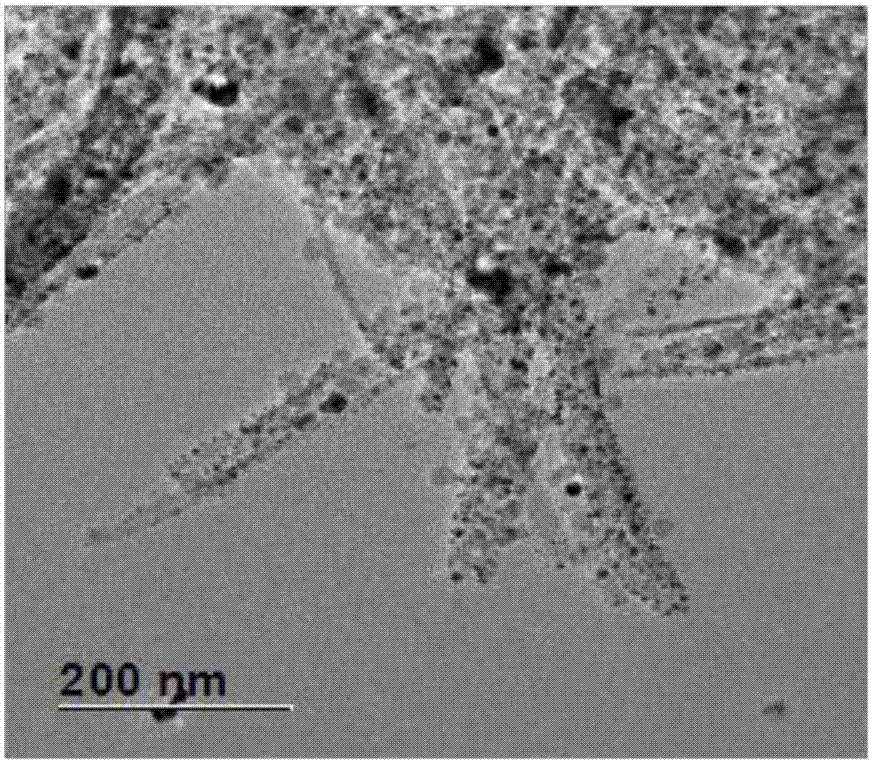

[0063] Preparation of attapulgite / silicon dioxide-nano-silver composite particles: Weigh a certain amount of attapulgite (AT) through thermal activation and dispersion treatment, and prepare attapulgite with a mass concentration of 1% water suspension, and then Silver nitrate solution according to (AgNO 3 / AT=17 / 100) was added to the attapulgite suspension, and stirred by magnetic force for 10 hours at 50°C. A certain amount of silica sol (produced by Qingdao Chemical Plant, brand ZA-25, SiO 2 Concentration of 25wt%, particle size of about 10 to 20nm, pH value of about 7) diluted with deionized water to a mass concentration of 1% and then added to the heat-treated attapulgite suspension, wherein the dry attapulgite and silicon dioxide The weight ratio is 100 / 5, stirred with a laboratory high-shear dispersing emulsifier at 10,000 rpm for 30 minutes, then sprayed i...

Embodiment 2

[0066] Embodiment 2 prepares antibacterial reverse osmosis composite membrane according to the following steps:

[0067] Preparation of attapulgite / silicon dioxide-nano-silver composite particles: Weigh a certain amount of attapulgite that has been heat-activated and dispersed, add distilled water to prepare a suspension with a mass concentration of attapulgite of 10%, and then add silver nitrate Solution according to (AgNO 3 / AT=17 / 100) was added to the attapulgite suspension, and stirred for 1 hour at 90°C. A certain amount of silicon dioxide powder (Shenyang Chemical Industry Co., Ltd., the particle size range is 10-30nm) is mixed with deionized water to prepare a mass concentration of 10%, and it is dispersed through a high-shear disperser (same as Example 1) to obtain a stable suspension. Get the silicon dioxide suspension obtained by dispersing heat and heat-treated attapulgite suspension and mix them according to the proportioning ratio of 5 / 100 of their respective dr...

Embodiment 3

[0070] Embodiment 3 prepares antibacterial reverse osmosis composite membrane according to the following steps:

[0071] Preparation of attapulgite / silicon dioxide-nano-silver composite inorganic antibacterial agent: Weigh a certain amount of attapulgite that has been heat-activated and dispersed, add distilled water to prepare a suspension with a mass concentration of attapulgite of 10%, and then put Silver nitrate solution according to (AgNO 3 / AT=17 / 100) was added to the attapulgite suspension, and stirred for 5 hours at 70°C. A certain amount of silicon dioxide powder (Shenyang Chemical Industry Co., Ltd., the particle size range is 10-30nm) is mixed with deionized water to prepare a mass concentration of 5%, and is dispersed by a high-shear disperser (same as Example 1) to obtain a stable suspension. Take the dispersed silicon dioxide suspension and mix it with the heat-treated attapulgite suspension according to the ratio of 5 / 100 of their dry weight, and carry out she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com