Liquid-liquid homogeneous method for synthesizing polyaryl ether by using continuous flow micro-channel reactor

A technology of microchannel reactor and channel reactor, which is applied in the field of liquid-liquid homogeneous method, can solve the problems of failing to realize large-scale production of all-water medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

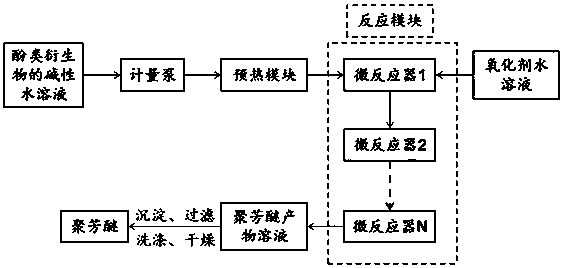

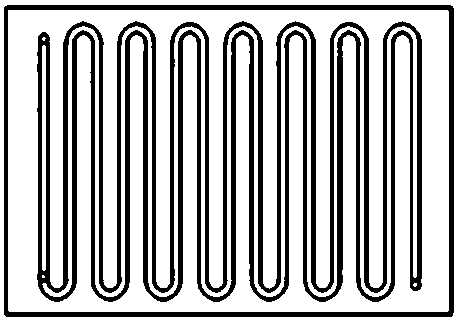

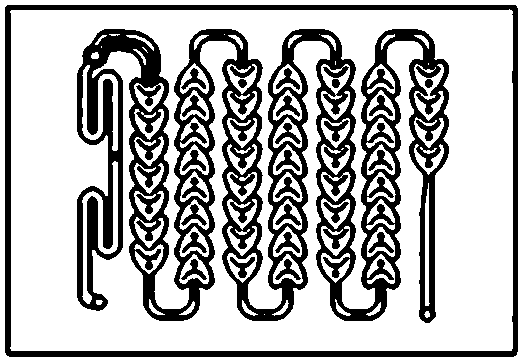

[0028] Embodiment 1: as attached figure 1 ,2 and attached image 3 As shown, configure 4wt% 2,6,-dimethylphenol sodium hydroxide aqueous solution, the pH value is controlled at 11, and add 0.75wt% sodium lauryl sulfate, stir slowly; then add 20wt% hydrogen peroxide 1.2wt% copper-ethylenediaminetetraacetic acid complex, stir evenly; inject 2,6,-dimethylphenol aqueous sodium hydroxide solution and hydrogen peroxide into the straight line of Corning high-throughput microchannel reactor through a metering pump The channel module is preheated, and the preheating temperature is set to 35°C, and the preheating residence time is 30s; the flux of the sodium hydroxide aqueous solution of 2,6,-dimethylphenol in the straight channel module is controlled at 3mL / min, and 2,6,-Dimethylphenol and H in hydrogen peroxide 2 o 2 The molar ratio between them is 1:1.2. The preheated 2,6,-dimethylphenol sodium hydroxide aqueous solution and hydrogen peroxide directly enter the reaction module co...

Embodiment 2

[0029] Embodiment 2: as attached figure 1 , 2 and attached image 3 As shown, configure 4wt% 2-methyl-6-bromophenol aqueous sodium hydroxide solution, the pH value is controlled at 11, and add 0.75wt% sodium lauryl sulfate, stir slowly; then add 1.2wt% copper-ethylenediaminetetraacetic acid complex, stir evenly; inject 2-methyl-6-bromophenol aqueous sodium hydroxide solution and hydrogen peroxide into the straight line of Corning high-throughput microchannel reactor through metering pump The channel module is preheated, the preheating temperature is set to 45°C, and the preheating residence time is 40s; the flux of the sodium hydroxide aqueous solution of 2-methyl-6-bromophenol in the straight channel module is controlled at 3mL / min, and 2-Methyl-6-bromophenol and H in hydrogen peroxide 2 o 2 The molar ratio between them is 1:1.2. The preheated 2-methyl-6-bromophenol aqueous sodium hydroxide solution and hydrogen peroxide directly enter the reaction module composed of 10 ...

Embodiment 3

[0030] Embodiment 3: as attached figure 1 , 2 and attached image 3 As shown, configure 8wt% 2,6,-dimethylphenol sodium hydroxide aqueous solution, the pH value is controlled at 11, and add 1.25wt% sodium lauryl sulfate, stir slowly; then add to 30wt% hydrogen peroxide 1.5wt% copper-ethylenediaminetetraacetic acid complex, stir evenly; inject 2,6,-dimethylphenol aqueous sodium hydroxide solution and hydrogen peroxide into the straight line of Corning high-throughput microchannel reactor through a metering pump The channel module is preheated, and the preheating temperature is set to 45°C, and the preheating residence time is 40s; the flux of the sodium hydroxide aqueous solution of 2,6,-dimethylphenol in the straight channel module is controlled at 2mL / min, and 2,6,-Dimethylphenol and H in hydrogen peroxide 2 o 2 The molar ratio between them is 1:1.2. The preheated 2,6,-dimethylphenol sodium hydroxide aqueous solution and hydrogen peroxide directly enter the reaction modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com