Nano ZSM-5 catalyst for alkylation of benzene and methanol and preparation method thereof

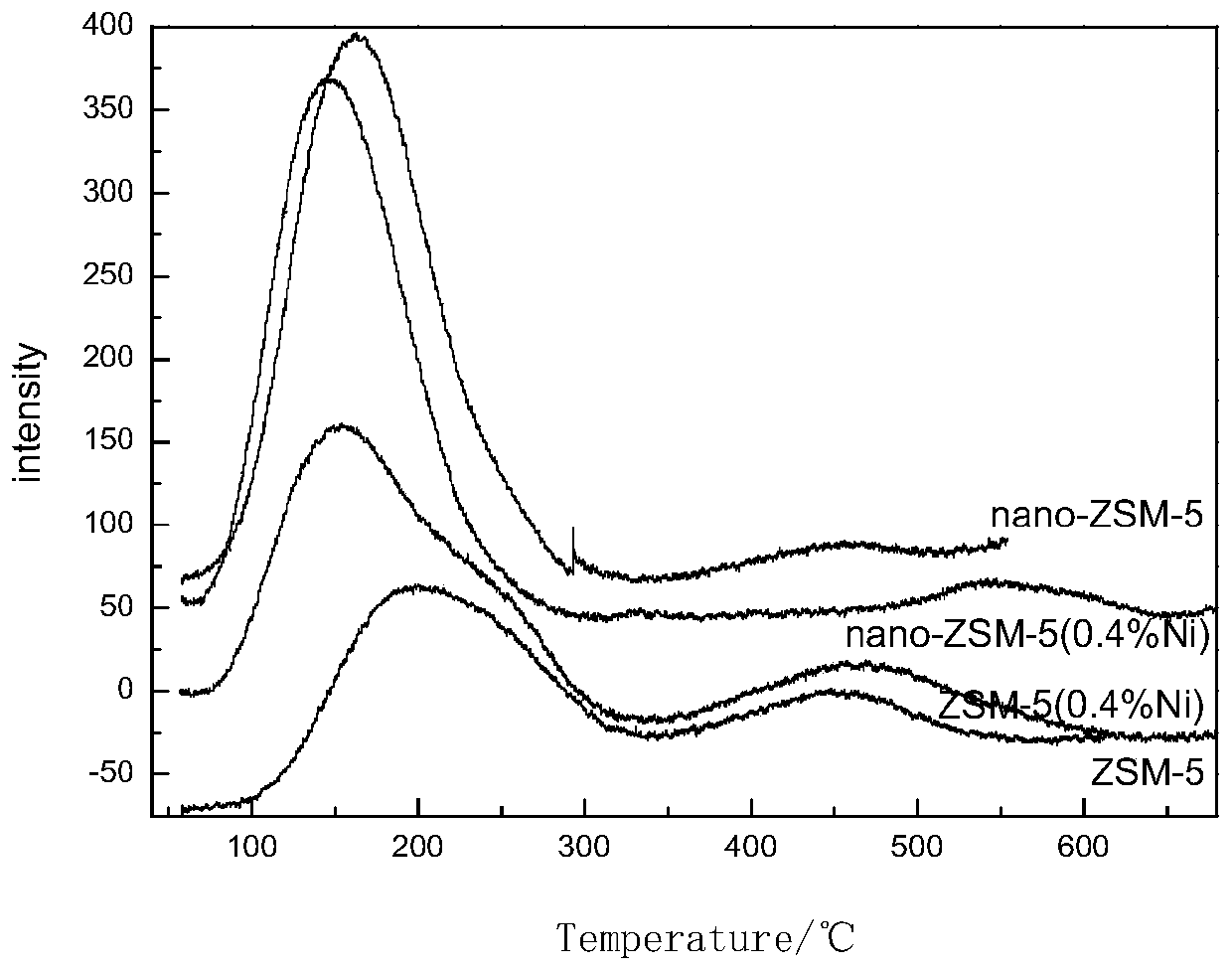

A technology of ZSM-5 and catalyst, applied in the field of nano-catalyst and its preparation, can solve the problems of many by-products, low yield of xylene, low conversion rate of benzene, etc., achieve fewer types of by-products, high catalyst activity, and improve conversion The effect of rate sum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

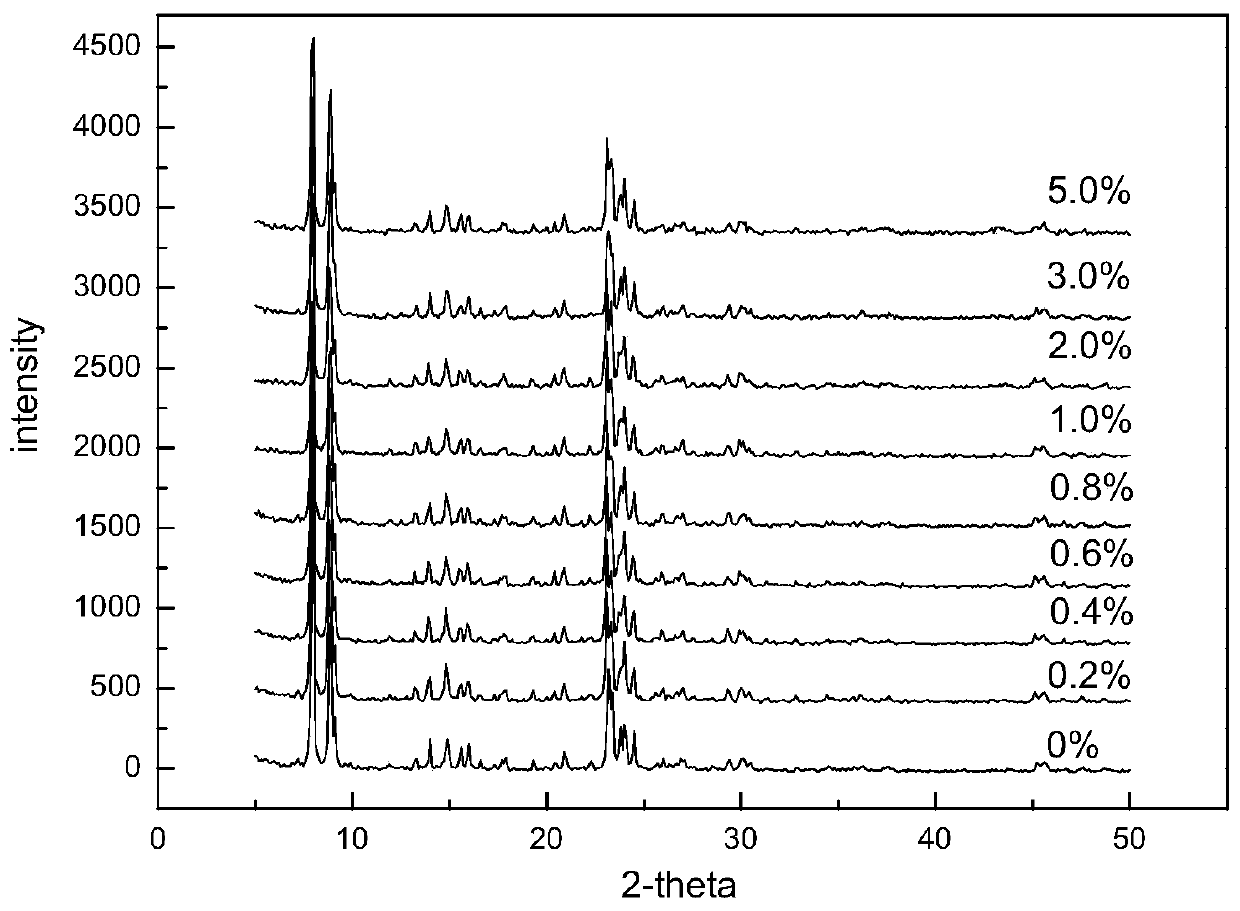

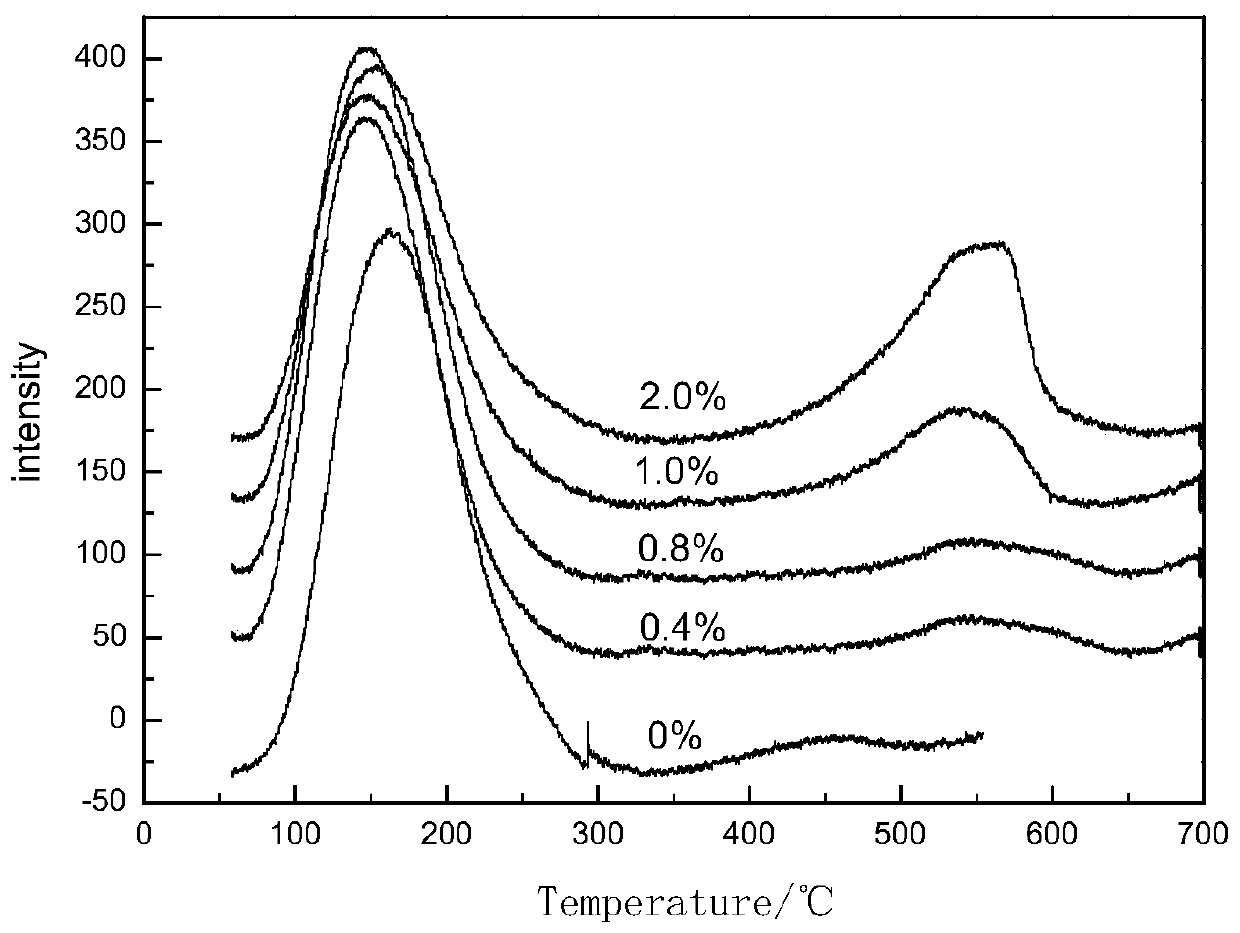

Method used

Image

Examples

Embodiment 1

[0051] (1) Preparation of raw catalyst powder

[0052] The raw materials include silicon source, aluminum source, template agent (M) is TPAOH, silane coupling agent (Q) is APTES, NaOH, and water. Prepare each raw material; mix template agent M19.3814g TPAOH and 34.8g water, and stir evenly. Add 0.051g of NaOH, mix well, stir to dissolve, continue to add 0.5g of aluminum source AIP, stir until it is completely hydrolyzed to obtain solution A, drop 26.097g of silicon source TEOS into the solution A, after 0.5h hydrolysis is complete, use The three-necked flask was refluxed in a water bath at 80°C for 24h to obtain a seed crystal solution; 1.362g of silane coupling agent (Q)APTES was added dropwise to the seed solution, rinsed with 20g water, stirred in a water bath at 80°C for 6h, and the resulting material Transfer to a high-pressure hydrothermal synthesis kettle with polytetrafluoroethylene lining, and crystallize at 170°C for 72 hours to obtain a crystalline product; after the c...

Embodiment 2

[0054] (1) Preparation of raw catalyst powder

[0055] The raw materials include silicon source, aluminum source, template (M) is TPAOH, silane coupling agent (Q) is APTES, NaOH, and water. Prepare each raw material; mix template M19.3814g TPAOH with 34.8g water, and stir evenly. Add 0.051g of NaOH, mix well, stir to dissolve, continue to add 0.5g of aluminum source AIP, stir until template M and NaOH are completely dissolved to obtain solution A, add 26.097g of silicon source TEOS to said solution A dropwise, after 0.5h After the hydrolysis is complete, use a three-necked flask to continue refluxing in a water bath at 80°C for 24h to obtain a seed solution; add 1.362g of the silane coupling agent (Q) APTES dropwise to the seed solution, rinse with 20g of water, and stir in a water bath at 80°C 6h, transfer the obtained material to a high-pressure hydrothermal synthesis kettle with polytetrafluoroethylene lining, and crystallize at 170°C for 72h to obtain a crystalline product; a...

Embodiment 3

[0067] (1) Preparation of raw catalyst powder

[0068] The raw materials include silicon source, aluminum source, template (M) is TPAOH, silane coupling agent (Q) is APTES, NaOH, and water. Prepare each raw material; mix template M19.3814g TPAOH with 34.8g water, and stir evenly. Add 0.051g of NaOH, mix well, stir to dissolve, continue to add 0.5g of aluminum source AIP, stir until template M and NaOH are completely dissolved to obtain solution A, add 26.097g of silicon source TEOS to said solution A dropwise, after 0.5h After the hydrolysis is complete, use a three-necked flask to continue refluxing in a water bath at 80°C for 24h to obtain a seed solution; add 1.362g of the silane coupling agent (Q) APTES dropwise to the seed solution, rinse with 20g of water, and stir in a water bath at 80°C 6h, transfer the obtained material to a high-pressure hydrothermal synthesis kettle with polytetrafluoroethylene lining, and crystallize at 170°C for 72h to obtain a crystalline product; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com