Laser MEMS microphone

A microphone and laser technology, applied in the field of microphones, can solve the problems of no significant improvement in the pickup signal-to-noise ratio and anti-electromagnetic interference ability, small size, etc., and achieve strong anti-electromagnetic interference ability, small size, and high pickup signal-to-noise ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

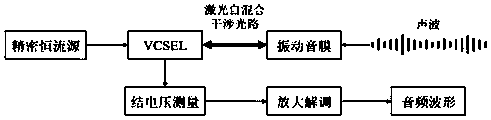

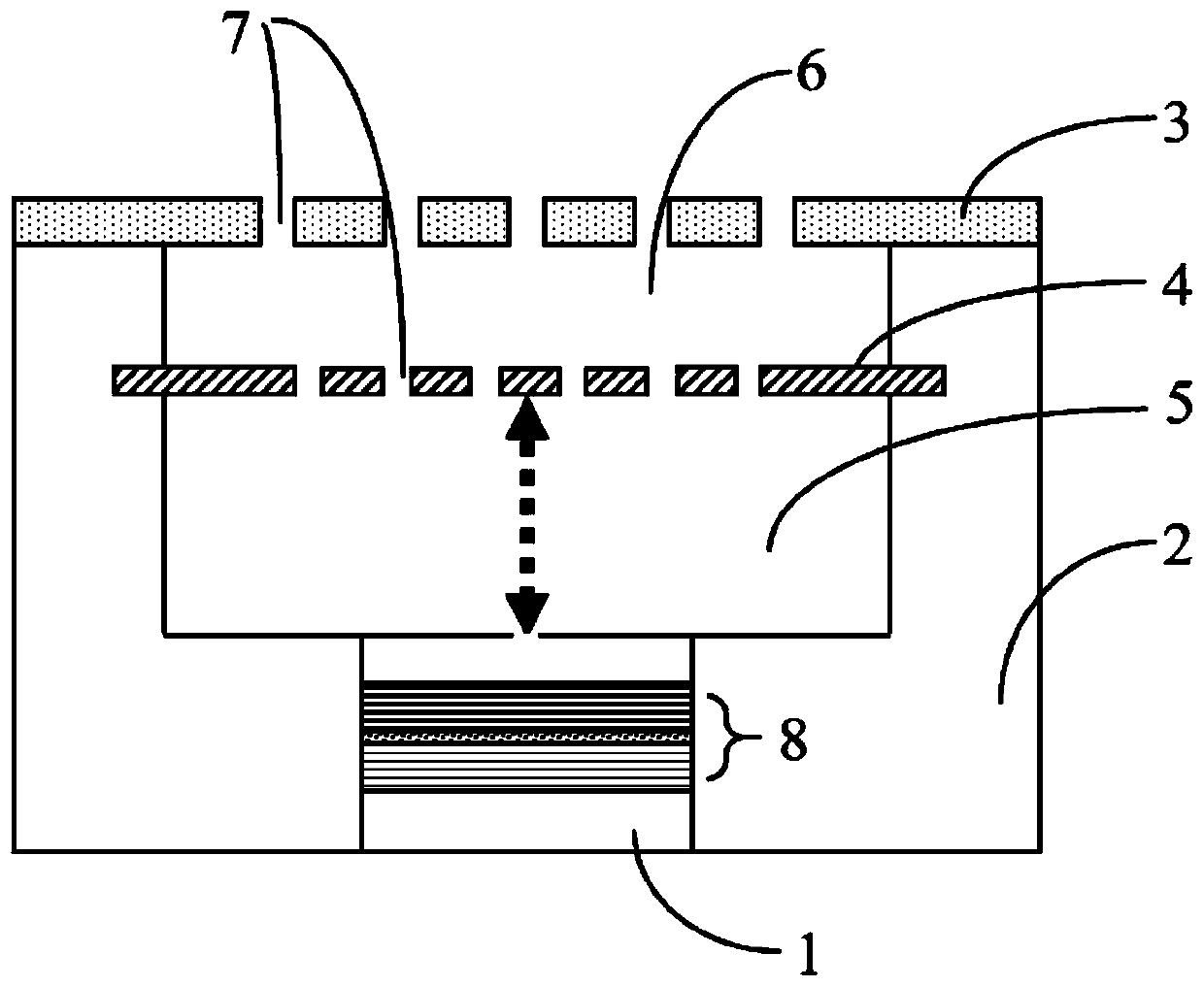

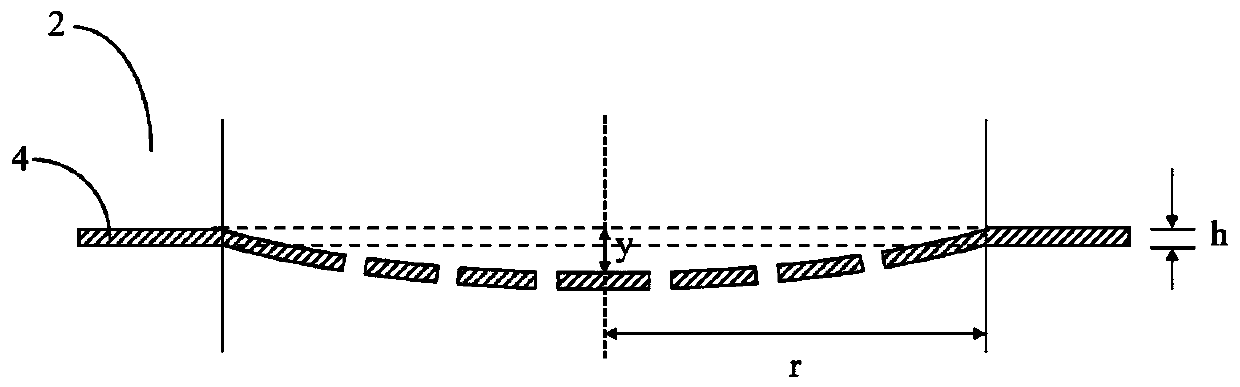

[0020] Such as figure 1 with Figure 4 As shown, the laser MEMS microphone provided by the present invention includes a light source 1 and a microphone structure, and the microphone structure includes a substrate 2, a back plate 3, a vibrating sound film 4, a front chamber 5 made of the substrate 2 and the vibrating sound film 4, and a The rear cavity 6 formed by the vibrating sound film 4 and the back plate 3; in this embodiment, the light source 1 is a VCSEL (vertical-cavity surface-emitting laser, vertical-cavity surface-emitting laser), and its threshold current is small, the divergence angle is small, and the frequency is stable Features such as are very suitable for application in the compact structure of the present invention. In this embodiment, a VCSEL with a center wavelength of 850 nm, a typical power of 0.5 mW, and a div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com