Interdigital PN-junction battery structure of IBC battery and fabrication method of interdigital PN-junction battery structure

An interdigitated, PN junction technology, applied in the field of solar cells, can solve the problems of general PN junction quality, effective collection of unfavorable currents, and high cost of IBC cells, to reduce the steps of multi-step masking and photolithography, and to improve cell photoelectricity. Conversion efficiency, avoiding the effect of uneven diffusion at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

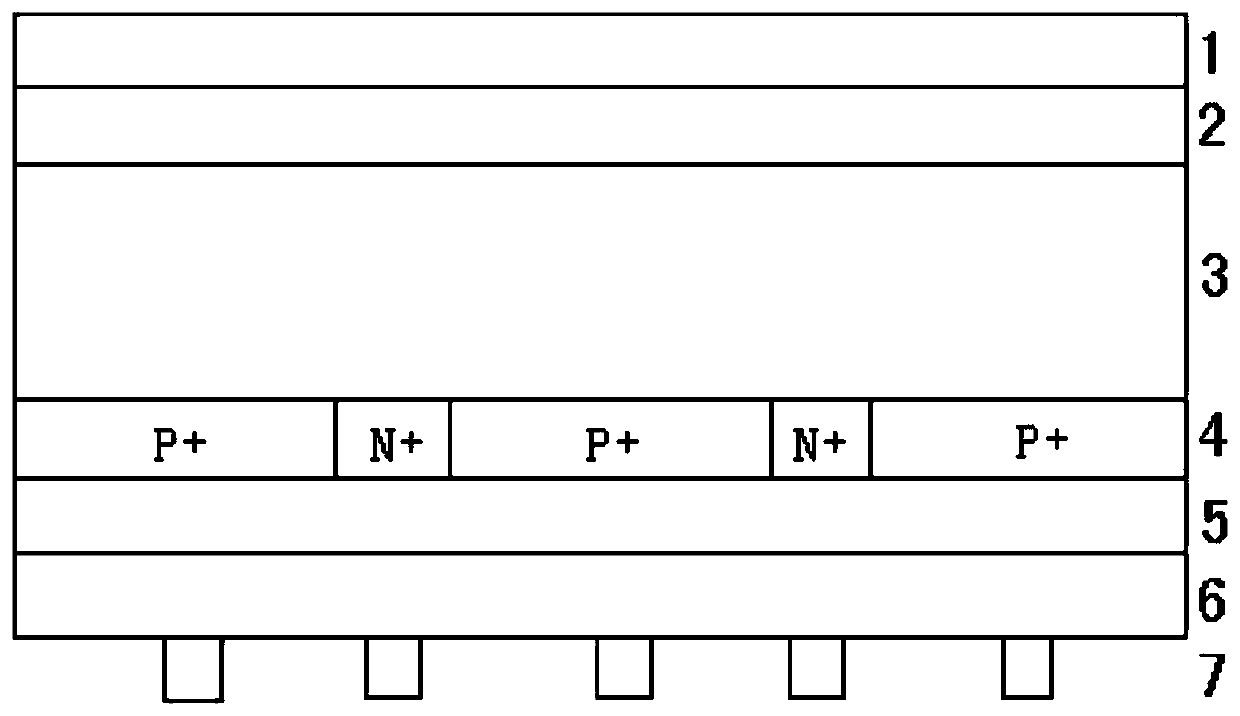

[0020] Such as figure 1 As shown, the battery structure of a kind of IBC battery interdigitated PN junction provided by the present invention, it comprises in turn: silicon nitride anti-reflection film layer 1, silicon dioxide thin film layer-2, N-type single crystal silicon chip substrate 3, interdigitated P district and N district layer 4, silicon dioxide thin film layer 2 5, aluminum oxide thin film layer 6; Each P district, N district is respectively inserted with a metal electrode 7, and metal electrode 7 is formed from the trioxide The surface of the aluminum thin film layer 6 is exposed.

[0021] The preparation method of the battery structure of the interdigitated PN junction of the above-mentioned IBC battery is as follows:

[0022] Step 1: Cleaning the monocrystalline silicon wafer for texturing, removing impurities on the surface of the silicon wafer, and at the same time completing the preparation of the pyramid textured surface to obtain an N-type monocrystalline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com