Laser cladding high-temperature protective coating surface polishing and purifying method based on pulsed electron beam technology

A technology of pulsed electron beams and protective coatings, which is applied in coatings, metal material coating processes, etc., can solve problems such as short pulse width, workpiece deformation, surface defects, etc., achieve high energy utilization, avoid coating oxidation, The effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Grinding and polishing the surface of the superalloy substrate, and cleaning it ultrasonically with acetone and alcohol;

[0025] (2) Prepare NiCrAlY high-temperature protective coating on the surface of the substrate by coaxial powder-feeding laser cladding technology, select according to the technical requirements of laser cladding equipment: spot diameter 3mm, laser power 1.0KW, scanning speed 10mm / s, lap joint Rate 20%, argon protection;

[0026] (3) Use pulsed electron beam technology to directly irradiate the NiCrAlY cladding layer, select according to the technical requirements of pulsed electron beam equipment: vacuum degree P≤8×10 -3 Pa, the energy density is 4J / cm 2 , pulse width 1.5μs, bombardment times 30 times

[0027] Using a scanning electron microscope to observe the surface morphology of the coating before and after pulsed electron beam irradiation treatment, there is a very thick layer of oxide skin on the original coating surface, and the surfac...

Embodiment 2

[0029] (1) Grinding and polishing the surface of the superalloy substrate, and cleaning it ultrasonically with acetone and alcohol;

[0030] (2) Prepare NiCoCrAlY high-temperature protective coating on the substrate surface by coaxial powder-feeding laser cladding technology, select according to the technical requirements of laser cladding equipment: spot diameter 3mm, laser power 1.3 kW, scanning speed 15mm / s, Receiving rate 35%, argon protection;

[0031] (3) Use pulsed electron beam technology to irradiate the NiCoCrAlY cladding layer, select according to the technical requirements of pulsed electron beam equipment: vacuum degree P≤8×10 -3 Pa, the energy density is 4J / cm 2 , pulse width 1.5μs, bombardment times 45 times

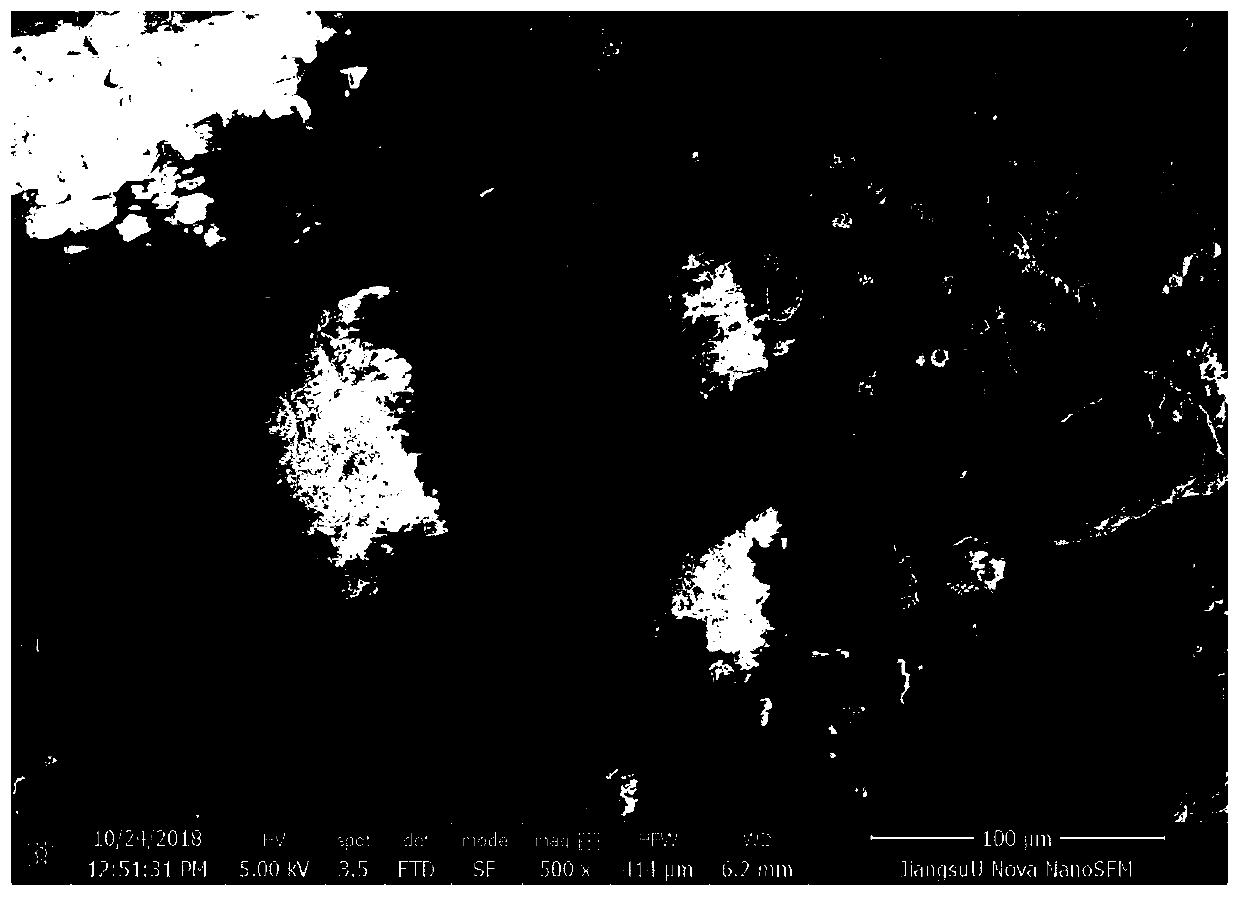

[0032] Scanning electron microscopy was used to observe the surface morphology of the coating before and after pulsed electron beam irradiation treatment, such as figure 1 As shown, there is a very thick layer of oxide skin on the surface of the laser c...

Embodiment 3

[0034] (1) Grinding and polishing the surface of the superalloy substrate, and cleaning it ultrasonically with acetone and alcohol;

[0035](2) CoNiCrAlY high-temperature protective coating was prepared on the surface of the substrate by coaxial powder-feeding laser cladding technology, selected according to the technical requirements of laser cladding equipment: spot diameter 3mm, laser power 2 kW, scanning speed 20mm / s, lap joint 50% rate,

[0036] (3) Use pulsed electron beam technology to irradiate CoNiCrAlY cladding layer, select according to the technical requirements of pulsed electron beam equipment: vacuum degree P≤8×10 -3 Pa, the energy density is 8J / cm 2 , pulse width 1.5 μs, bombardment times 60 times

[0037] Scanning electron microscopy was used to observe the surface morphology of the coating before and after pulsed electron beam irradiation treatment. The surface oxide scale of the laser cladding CoNiCrAlY protective coating is thicker, and the surface perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com