Nano silicon carbide and nano cerium oxide synergetically enhanced metal matrix micro-nano powder and preparing method thereof

A technology of nano-silicon carbide powder and nano-cerium oxide, applied in the direction of coating, etc., to achieve good application prospects, improve wettability, and strong engineering practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

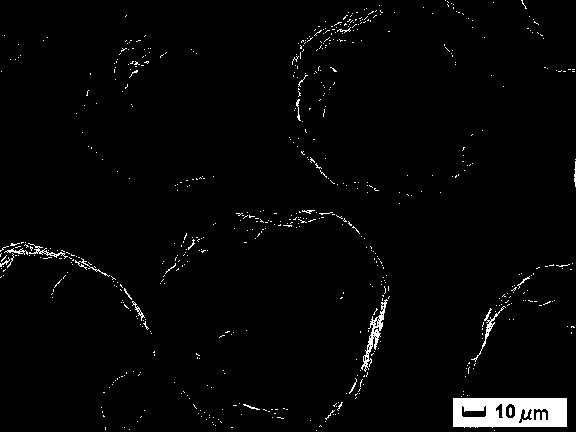

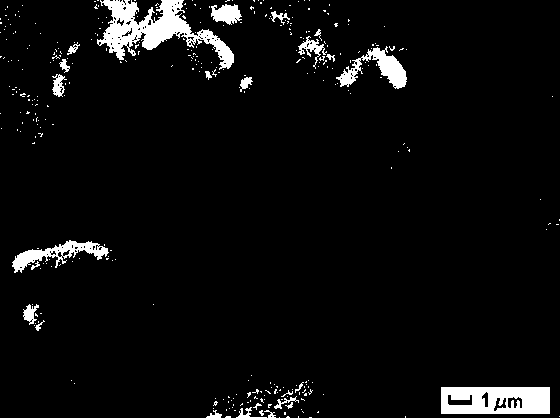

example 1

[0038] The materials used in this embodiment: nanometer silicon carbide powder with an average particle size of 20nm and a mass fraction of 2.25%; nanometer cerium oxide powder with an average particle size of 20nm and a mass fraction of 3%; the micron metal powder is Al-Si alloy powder, The average particle size is 50μm, and the mass fraction is 94.75%. The metal-based micro-nano powder enhanced by nano-silicon carbide and nano-cerium oxide is prepared by the above method steps. The specific parameters are: the ethanol in the mixed solution of ethanol and water used in the nano suspension The volume ratio is 50%; the ball milling compound parameters are: the ball milling speed is 200 rpm, the ball-to-material ratio is 8:1, and the ball milling time is 1 hour. Observed by scanning electron microscope, the prepared micro-nano powder maintains the spherical characteristics of micron powder ( figure 1 ), the surface is covered with a large amount of nano silicon carbide powder and ...

example 2

[0040] The materials used in this example: nano silicon carbide powder with an average particle size of 10nm and a mass fraction of 1.5%; nano cerium oxide powder with an average particle size of 10nm and a mass fraction of 2%; the micron metal powder is Al-Si alloy powder with an average The particle size is 50μm, and the mass fraction is 96.5%; the metal-based micro-nano powder enhanced by nano-silicon carbide and nano-cerium oxide is prepared by the above method steps. The specific parameters are: the ethanol in the mixed solution of ethanol and water used in the nano suspension The volume ratio is 30%; the ball milling compound parameters are: the ball milling speed is 100 rpm, the ball-to-material ratio is 5:1, and the ball milling time is 0.5 hours. Observed by scanning electron microscope, in the prepared micro-nano powder, nano-silicon carbide powder and nano-cerium oxide powder are coated on the surface of micron metal particles with high dispersibility characteristics ...

example 3

[0042] The materials used in this example: nano silicon carbide powder with an average particle size of 30nm and a mass fraction of 3%; nano cerium oxide powder with an average particle size of 30nm and a mass fraction of 4%; the micron metal powder is Al-Si alloy powder with an average The particle size is 50μm, and the mass fraction is 93%. The metal-based micro-nano powder enhanced by nano-silicon carbide and nano-cerium oxide is prepared by using the above method steps. The specific parameters are: ethanol in the mixed solution of ethanol and water used in the nano suspension The volume ratio is 70%; the ball milling compound parameters are: the ball milling speed is 300 rpm, the ball-to-material ratio is 10:1, and the ball milling time is 1.5 hours. Observed by scanning electron microscope, in the prepared micro-nano powder, nano-silicon carbide powder and nano-cerium oxide powder are coated on the surface of micron metal particles with high dispersibility characteristics t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com