Single crystal single domain piezoelectric film and preparation method thereof

A technology of piezoelectric thin film and single crystal thin film, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc. High cost and other issues, to achieve the effect of no drop in electromechanical coupling coefficient, stable piezoelectric performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

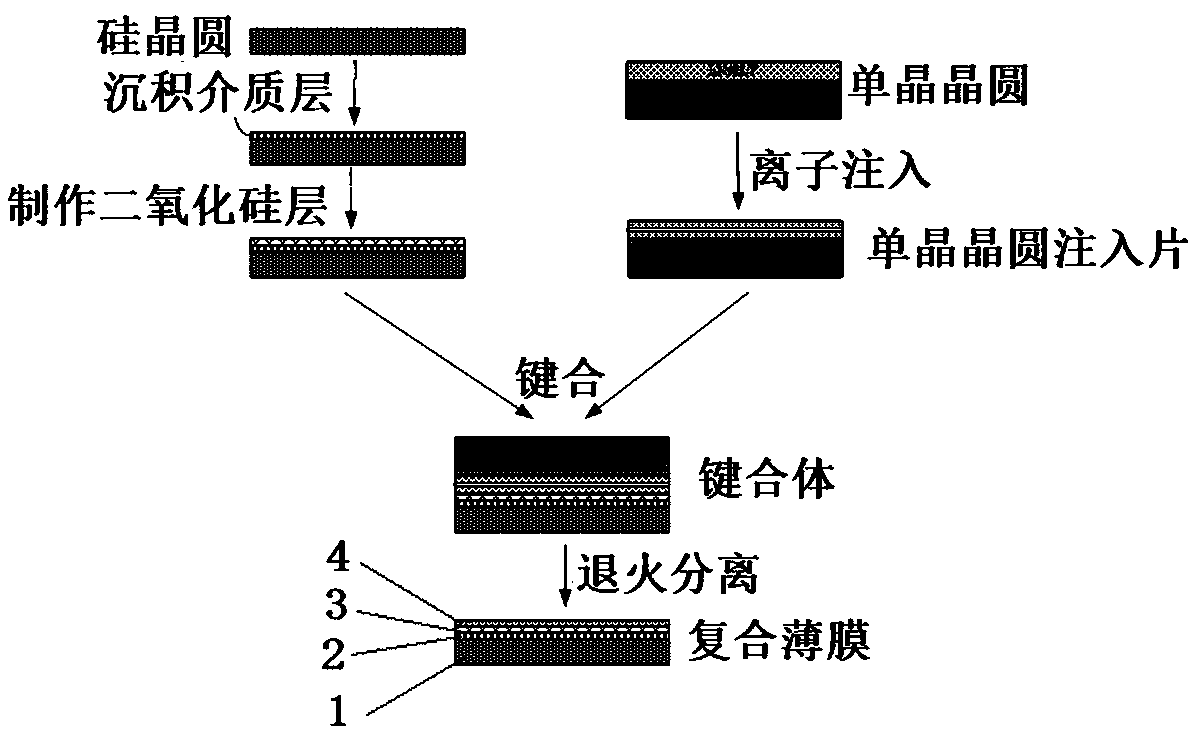

[0038] The present invention also includes a method for preparing a single crystal single domain piezoelectric film, comprising the following steps:

[0039] Preparation of composite films;

[0040] Put the composite film in an annealing furnace at 450-590°C and keep it warm for 5-30 minutes; or, put the composite film in an annealing furnace to heat up and anneal, and use an ion gun to spray charged ions onto the surface of the composite film during the heating process to obtain a single crystal Monodomain piezoelectric films.

[0041] The composite thin film of the present invention can be any existing single crystal thin film, such as lithium niobate thin film, lithium tantalate thin film, etc., all of which can be obtained by the method described in the present invention.

[0042] Preferably, the composite film is put into an annealing furnace during the temperature-raising annealing process, and the temperature is raised to 450-590° C. at a rate of 2-15° C. / minute.

[0...

Embodiment 1

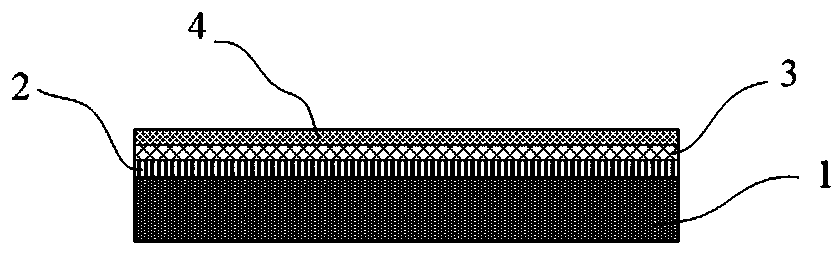

[0057] A single-crystal single-domain piezoelectric film, which sequentially includes a single-crystal film layer, a silicon dioxide layer, a dielectric layer, and a single-crystal silicon layer; wherein the material of the single-crystal film layer is single-crystal lithium niobate, and the ferroelectric domain is a single-domain , The piezoelectric coefficient is 98% to 100% of the bulk material; the dielectric layer is the damaged layer of single crystal silicon.

[0058] The single crystal lithium niobate in the material of the single crystal thin film layer can be replaced by single crystal lithium tantalate; the damaged layer of single crystal silicon in the dielectric layer can be replaced by amorphous silicon or polycrystalline silicon.

Embodiment 2

[0060] A single-crystal single-domain piezoelectric film, which sequentially includes a single-crystal film layer, a silicon dioxide layer, a dielectric layer, and a single-crystal silicon layer; wherein the material of the single-crystal film layer is single-crystal lithium niobate, and the ferroelectric domain is a single-domain , The piezoelectric coefficient is 98% to 100% of the bulk material; the dielectric layer is the damaged layer of single crystal silicon.

[0061] The thickness of the single crystal thin film layer is 100nm, the thickness of the silicon dioxide layer is 100nm; the thickness of the dielectric layer is 100nm, and the thickness of the single crystal silicon is 200μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com