High-adhesiveness low-temperature conductive silver paste for solar HIT battery and preparation method thereof

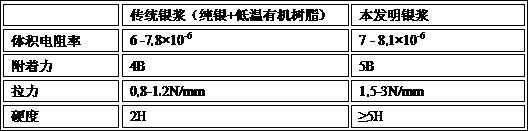

A technology of conductive silver paste and adhesion, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of high cost of conductive grids, reduced viscosity, easy tearing, etc. Achieve the effect of meeting the requirements of screen printing grid, good adhesion and tension, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A low-temperature conductive silver paste with strong adhesion for solar HIT batteries is made of the following materials by mass percentage: silver powder 37%-40%, silver-coated copper powder 39%-43%, resin 6%-7.5% %, diluent 0%-1.5%, curing agent 2%-3%, dispersant 0.4%-0.6%, first indium alloy powder 6%-7%, second indium alloy powder 3%-5%.

Embodiment 2

[0023] Embodiment 2: A low-temperature conductive silver paste with strong adhesion for solar HIT batteries is made of the following materials in mass percentage: 37% silver powder, 43% silver-coated copper powder, 7.5% resin, 2% curing agent, and dispersant 0.5%, the first indium alloy powder 7%, and the second indium alloy powder 3%.

Embodiment 3

[0024] Embodiment 3: A low-temperature conductive silver paste with strong adhesion for solar HIT batteries is made of the following materials in mass percentage: 40% silver powder, 39% silver-coated copper powder, 6% resin, 1.5% thinner, curing agent 2%, dispersant 0.5%, first indium alloy powder 6%, second indium alloy powder 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com