High-hardness AlTiN/AlTiSiN multi-layer nano composite coating and preparation process thereof

A nanocomposite coating and preparation technology, which is applied in metal material coating technology, coating, ion implantation plating, etc., can solve the problems that cannot meet the requirements of high hardness, high toughness and wear resistance, and achieve high-temperature thermal Good stability and corrosion resistance, good wear resistance, high hardness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

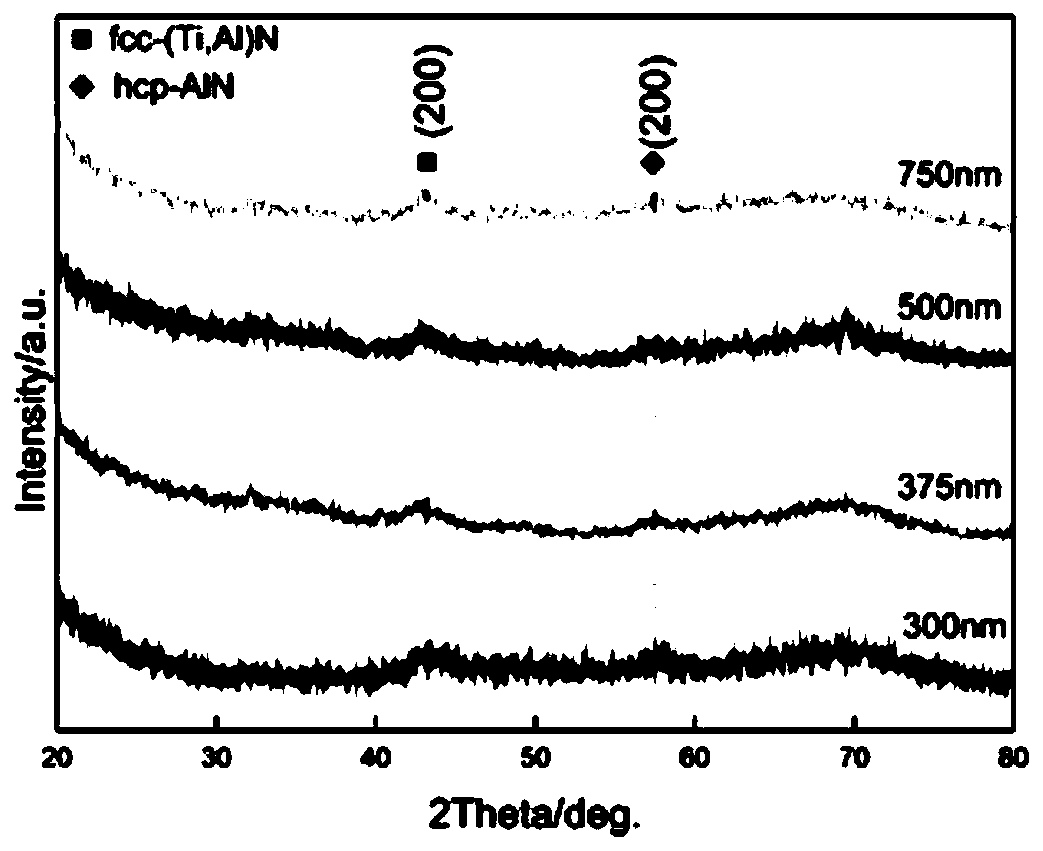

Image

Examples

Embodiment 1

[0037] In this embodiment, an AlTiN / AlTiSiN multilayer nanocomposite coating is deposited on a polished 304 stainless steel sheet, and the sample size is 25×30×1 mm.

[0038] The substrate is pretreated first: ultrasonic cleaning in acetone and alcohol for 15 minutes each, then blown dry with high-purity nitrogen, and then placed on the sample holder in the vacuum chamber.

[0039] The coating process was carried out on an AIP-650 arc ion coating machine, using pure metal Ti targets, alloy AlTi targets, and alloy AlTiSi targets (all with a purity of 99.9wt.%) with a diameter of 100 mm as the target materials, and the working gas and reaction gas were respectively Use high-purity argon and nitrogen.

[0040] The targets are evenly distributed on the inner wall of the furnace of the arc ion plating equipment to ensure a high plasma concentration in the furnace chamber during the deposition process; the pretreated substrate is placed on the central turret of the coating chamber; ...

Embodiment 2

[0052] In this embodiment, AlTiN / AlTiSiN multi-layer nanocomposite coating is deposited on a polished cemented carbide substrate, and the sample size is 25×30×3 mm.

[0053] The substrate is firstly pretreated: ultrasonically cleaned in acetone and alcohol for 15 mm each, then dried with high-purity nitrogen, and then placed on the sample holder in the vacuum chamber.

[0054] The coating process is carried out on an AIP-650 arc ion coating machine. The target material is a pure metal Ti target, an alloy AlTi target, and an AlTiSi alloy target (all with a purity of wt.99.9%) with a diameter of 100 mm. The working gas and reaction The gases are respectively high-purity argon and nitrogen.

[0055] Each target is evenly placed around the vacuum chamber of the arc ion plating equipment to ensure a high plasma concentration in the furnace chamber during the deposition process; the pretreated substrate is placed on the central turret of the coating chamber;

[0056] Use a mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com