Laser-enhanced three-dimensional micro-region electro-deposition method and corresponding device thereof

An electrodeposition device and electrodeposition technology, applied in the field of electrodeposition, can solve the problems of low deposition rate, extremely high relative displacement accuracy, and increased system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

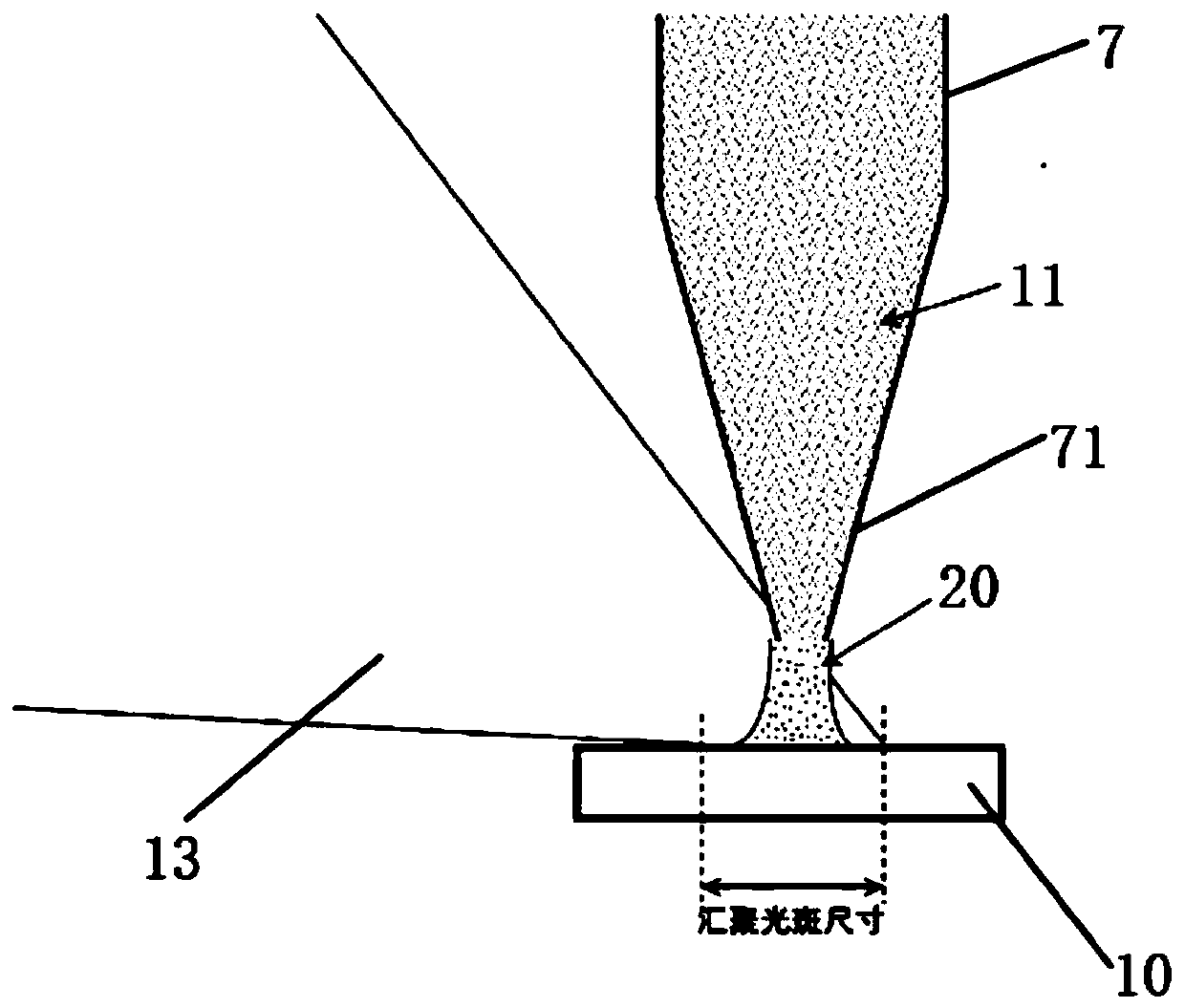

[0067] In this embodiment, an application of the present invention is described by taking electrodeposition of copper nanowires along the X direction as an example.

[0068] Electrolyte is CuSO 4 ·5H 2 For a uniform aqueous solution of O, the molar concentration of the solute is between 0.01-1M according to the requirements of the size and rate of the deposited nanowires. The capillary (outer diameter 1 mm, inner diameter 0.5 mm) was sharpened by a commercial needle puller, and the outer diameter of the capillary tip was about 1 μm after treatment. The 10mL glass syringe was filled with electrolyte, and the syringe was connected to the capillary through an adapter, and the electrolyte tube in the syringe was injected into the capillary through a syringe pump, and micro-droplets appeared at the tip of the stretching section of the capillary. The samples were heavily doped silicon wafers without oxide layer, and the silicon wafers were rinsed with hydrofluoric acid before elec...

specific Embodiment 2

[0070] In this embodiment, the application of the present invention in vertical nanowire growth is illustrated by taking electrodeposition of copper nanowires along the direction perpendicular to the sample surface as an example.

[0071] The reagents, materials and system configuration used are the same as those in Example 1. Before the approaching operation, the adjusted and converged laser spot is irradiated on the contact surface between the droplet 20 at the tip of the capillary and the surface of the sample 10 . Then, according to embodiment 1, the capillary is approached to the sample surface under the positive bias of the copper wire until the ammeter detects an appreciable number ( Figure 4 a). The electrodeposition process begins, and the copper layer is deposited on the sample surface, forming deposited copper 21 ( Figure 4 b). Subsequently, the computer controls the Z-direction electric control platform to move slowly along the vertical direction of the sample...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com