Antistatic polymer composition

An antistatic, polymer technology, applied in the field of polymer materials, can solve the problems of low yield and practicality, can not significantly reduce the system resistance, and the processing conditions are very limited, so as to achieve good enhancement effect and good processing environment , the effect of processing window width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

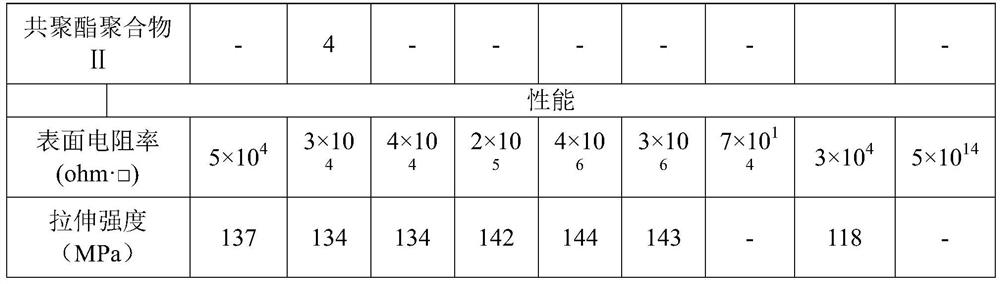

Examples

Embodiment Construction

[0023] The technical solutions of the present invention are further explained below in conjunction with specific examples.

[0024] The following materials were used in Examples and Comparative Examples:

[0025] Polybutylene terephthalate (PBT), PBT resin obtained from Changchun Artificial Resin Factory (Taiwan, China), trade name 1100, the crystallization temperature (Tc) is about 190°C, the melting temperature (Tm) is about 225°C, and the glass transition temperature (Tg) is 40°C.

[0026] Carbon fiber, carbon fiber obtained from Zoltek (U.S.A.) under the trade name Panex TM 35 chopped fibers (Type-45), the tensile strength is about 4000MPa, and the density is about 1.8g / cm 3 , with an average diameter of about 7 μm and an average length of about 6 mm.

[0027] Copolyester polymer Ⅰ, polyester polyether copolymer resin obtained from Nantong GCL Hot Melt Adhesive Co., Ltd., with a PBT segment content of about 94wt.%, a PTMG ether content of about 6wt.%, and a melting te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com