A method for strengthening installation and removal of high-interference retention bushings

An installation method and bushing technology, applied in the field of mechanical processing, can solve problems such as not easy to replace, unable to strengthen the base material, and limited operating space, so as to achieve the effects of reducing initial damage, improving assembly quality, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] This embodiment provides a method for strengthening the installation and disassembly of a single-ear high-interference stagnation straight-through bush. Such as Figure 10a As shown, the specific installation process is:

[0085] The enhanced installation process for the Single Lug High Interference Retention Thru Bushing includes:

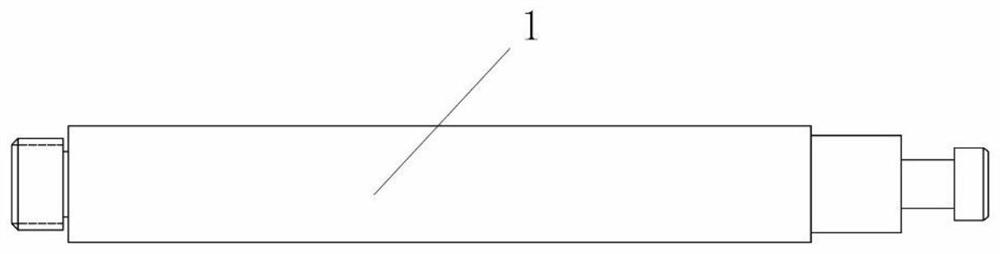

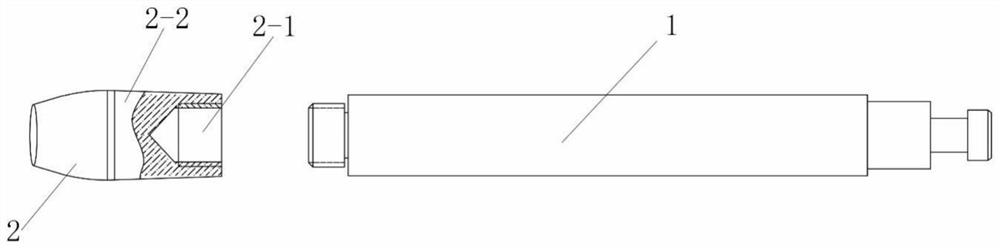

[0086] The cold extrusion installation tools selected in the installation process include: combined mandrel, pulling gun and installation nose cap.

[0087] Define the position of the prepared hole, such as Figure 9 Shown:

[0088] The distance from the right side of the hole to the nearest obstacle is: positive clearance;

[0089] The distance from the left side of the hole to the nearest obstacle is: back to the clearance;

[0090] The distance from the centerline of the hole to the upper obstacle is: upper clearance;

[0091] The distance from the hole centerline to the lower end obstacle is: lower end clearance.

[0092] The pos...

Embodiment 2

[0109] This embodiment provides a method for strengthening the installation and disassembly of a single-ear high-interference stagnation flange bush. Such as Figure 12a with 12b As shown, the specific installation and end face pressing process is as follows:

[0110] The enhanced installation process for single lug high interference retention flange bushings includes:

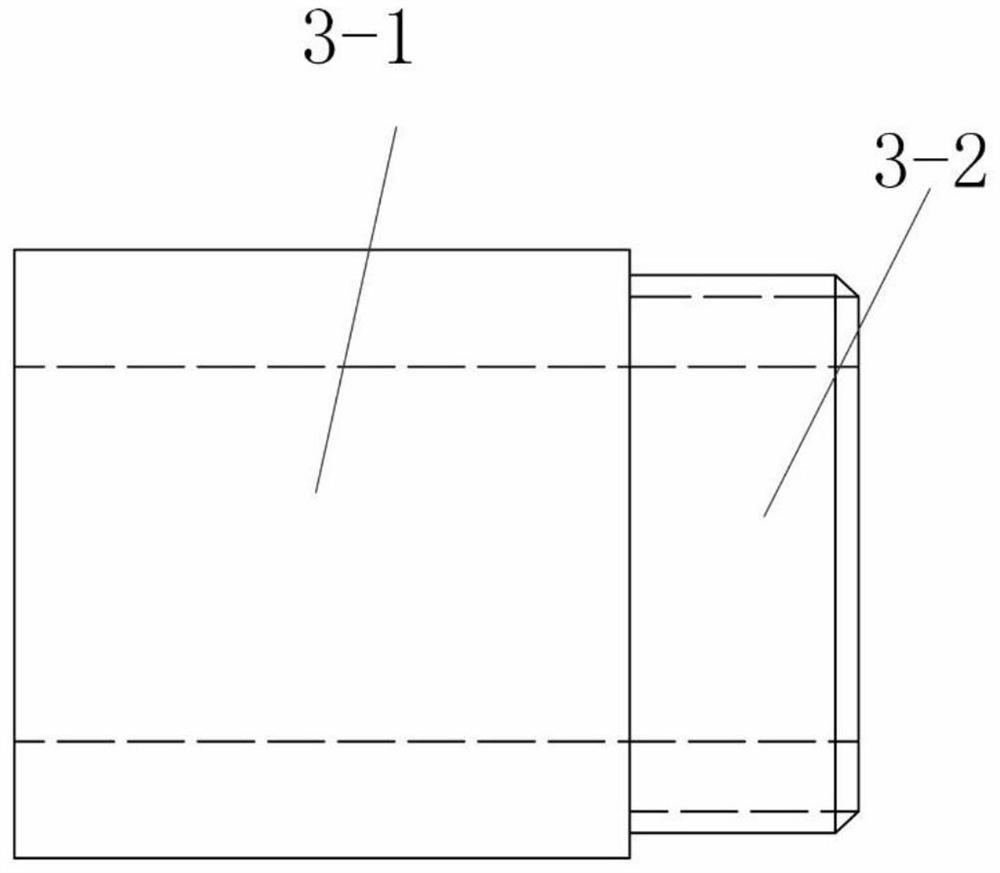

[0111] The cold extrusion installation tools selected in the installation process include: combined mandrel, pull gun, installation nose cap 3 and end surface pressing assembly.

[0112] S1. Make holes on the base material, the base material is: aluminum alloy material, and the position of the holes made is limited, such as Figure 11 Shown:

[0113] The distance from the right side of the hole to the nearest obstacle is: positive clearance;

[0114] The distance from the left side of the hole to the nearest obstacle is: back to the clearance;

[0115] The distance from the centerline of the hole to the ...

Embodiment 3

[0134] This embodiment provides a double-ear high-interference stagnation straight-through bushing strengthening installation and disassembly method. Such as Figure 15 As shown, the specific installation process is:

[0135] The enhanced installation process for double lug high interference retention thru bushings includes:

[0136] The cold extrusion installation tools selected in the installation process include: a combined mandrel, a pull gun, a nose cap 3, and a telescopic pad 4.

[0137] S1. Make two initial holes with coincident centerlines and the same diameter on the base material. The base material is made of high carbon steel, and the position of the prepared holes is limited, such as Figure 14 As shown: the position of the hole is limited by the operating space, the initial hole at the distal end of the operation is defined as the initial hole A, the installed through-through bushing 11 is defined as the bushing A, and the initial hole at the proximal end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com