Full premixed water-cooled low nitrogen condensing stainless steel hot water boiler

A hot water boiler and stainless steel technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of poor flame stability, large boiler volume, high defect rate, etc., and achieve reduced heat exchange equipment volume and strong environmental adaptability , The effect of reducing the heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present application will be further described in detail below in conjunction with specific embodiments.

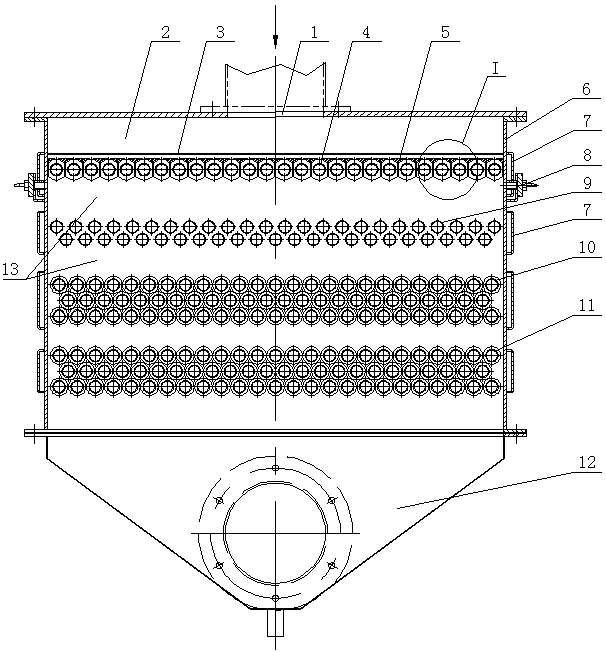

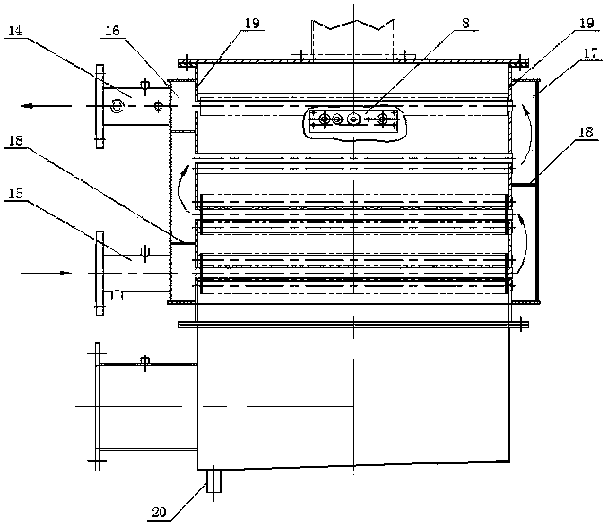

[0031] see Figure 1 to Figure 3 , the fully premixed water-cooled combustion low-nitrogen condensing stainless steel hot water boiler in this embodiment includes a water-cooled burner, a low-temperature furnace, a primary heat exchanger, a secondary condensing heat exchanger, and a flue gas collector arranged from top to bottom And water chamber, body frame.

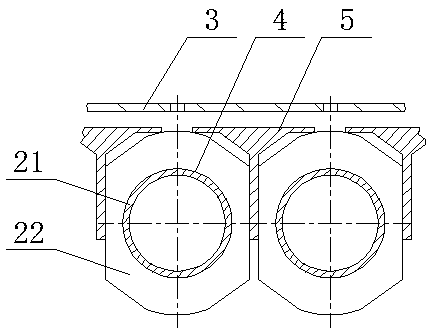

[0032] The water-cooled burner includes a burner spiral-finned tube 4, a distribution plate 3, a deflector 5, a buffer chamber 2, and an air inlet 1. The burner spiral-finned tube 4 is a laser-welded stainless steel spiral-finned tube. The fins are folded into a polygonal shape, and a deflector 5 is arranged between the pipes. In this embodiment, the deflector 5 is a T-shaped structure, and structures of other shapes can also be used. A distribution plate 3 is arranged on the upper part of the pipe. For...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com