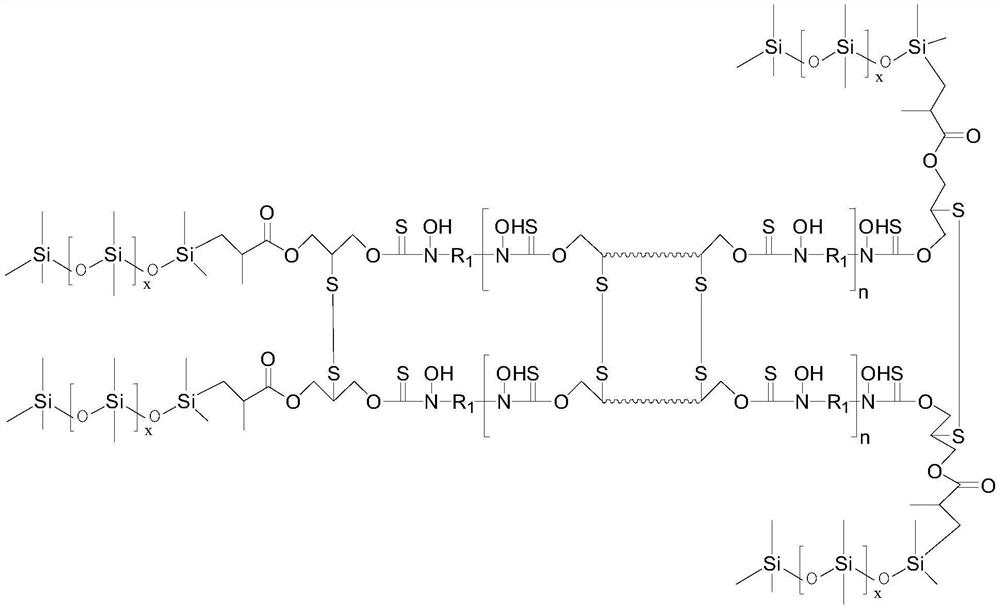

A kind of room temperature self-healing material and preparation method thereof

A self-healing material, room temperature technology, used in antifouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of increased material maintenance costs, limited use requirements, limited repair times, etc. The effect of self-healing, prolonging service life, large water contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

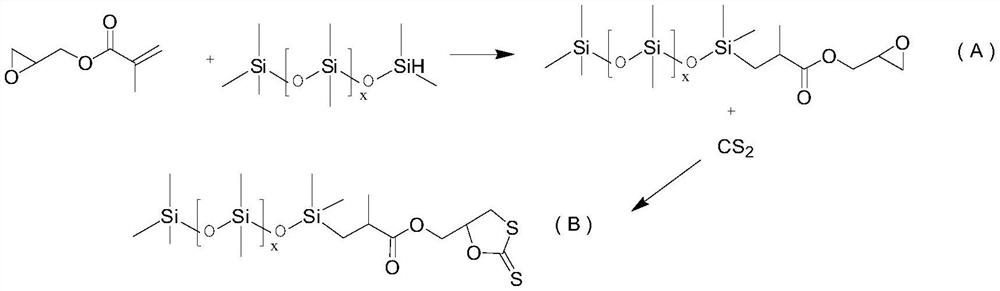

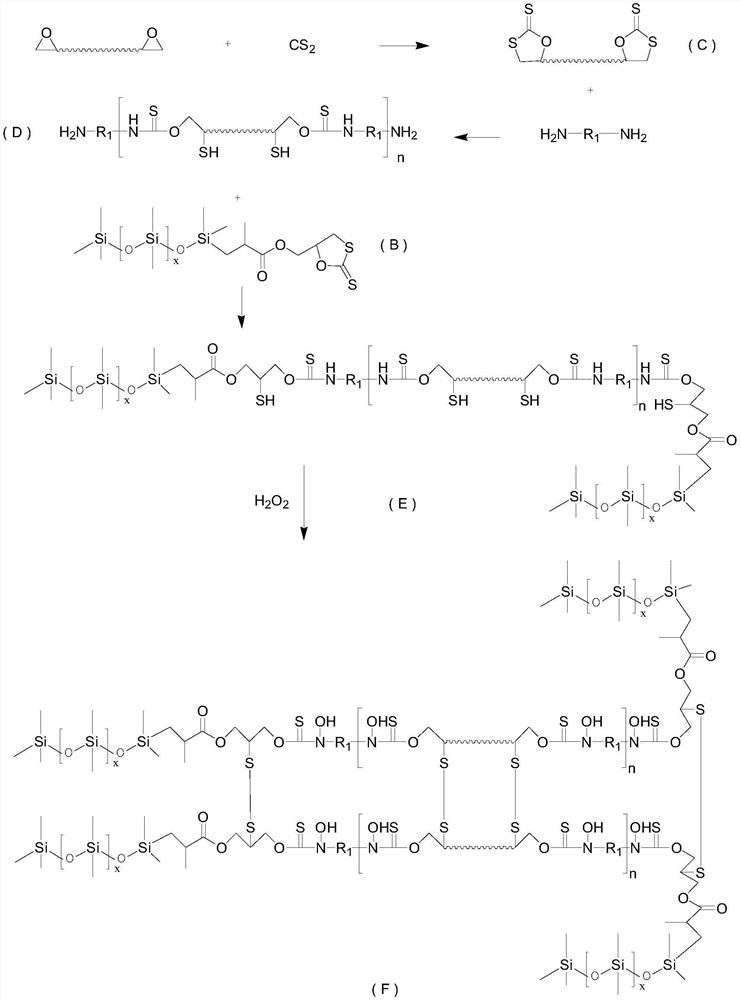

[0052]Step 1) Dissolve 1 part of one-end hydrogen-containing siloxane in 50 parts of tetrahydrofuran, 1.1 parts of glycidyl methacrylate, 1 wt % hydroquinone, 10 -5 10 parts of chloroplatinic acid, dissolved in 10 parts of tetrahydrofuran and added to the constant pressure dropping funnel, the dropping speed was controlled, stirred, and reacted at 60°C for 5 hours, the solvent was distilled off under reduced pressure, and 30 parts of toluene, excess sodium bicarbonate and 10 parts of Deionized water, stirred at 60°C for 3h, separated the water phase, took the organic layer, and distilled off the solvent under reduced pressure to obtain a siloxane-modified epoxy monomer (IR: 1642cm -1 : C=C disappeared; 1718cm -1 : C=O exists; 910cm -1 : presence of epoxy group; 800cm -1 、1080cm -1 : -Si-O exists), denoted as A;

[0053] The dosage of hydroquinone is 1% of the mass of glycidyl methacrylate.

[0054] Step 2) Dissolve 1 part of A, 2% lithium chloride (LiCl), 1 part of carbon...

specific Embodiment 2-8

[0062] Specific embodiment 2-8, other are with specific embodiment 1, difference is following table:

[0063]

[0064]

[0065] The room temperature self-healing material obtained in specific example 1 was used as the base material of the application example, and it was formulated into a room temperature self-healing varnish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com