Low-density dual-phase high-entropy alloy material and preparing method thereof

A high-entropy alloy and low-density technology, applied in the field of new metal materials, can solve problems such as limiting practicability, achieve the effects of improving density and mechanics, good promotion and application prospects, and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Composition Design of High Entropy Alloy

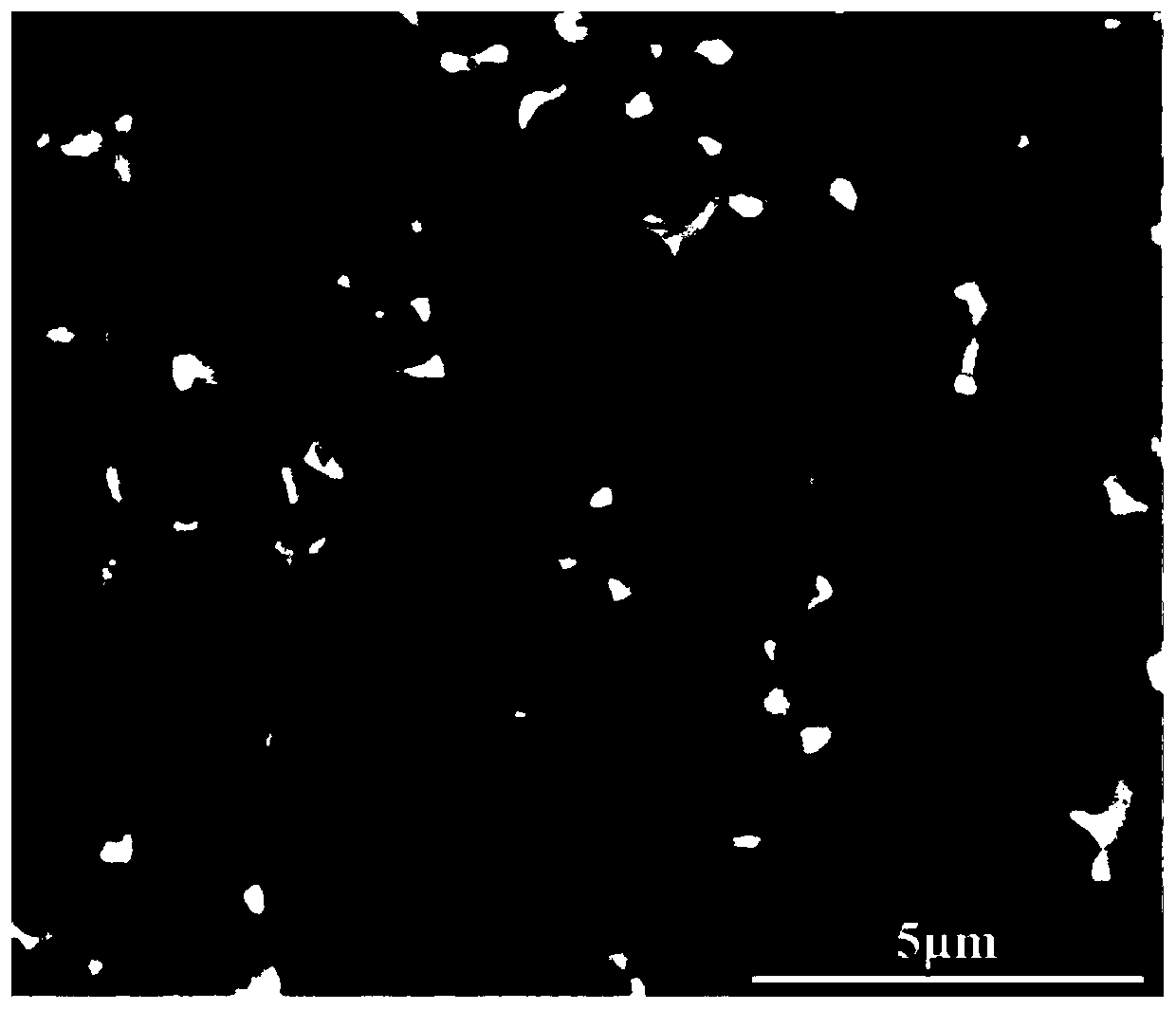

[0040] AlTiCrNiCu high-entropy alloy was designed with a theoretical density of 6.44g / cm 3 , according to the molar atomic ratio of the main elements in the high-entropy alloy AlTiCrNiCu 1:1:1:1:1, the mass of each component is calculated as Al powder 43.33g, Ti powder 76.87g, Cr powder 83.50g, Ni powder 94.25 g. Cu powder 102.05g, weigh the corresponding mass with an electronic balance, put the powder into a container, and pass through the argon gas protection, and then mix the powder on a V-type mixer for 48h until uniform.

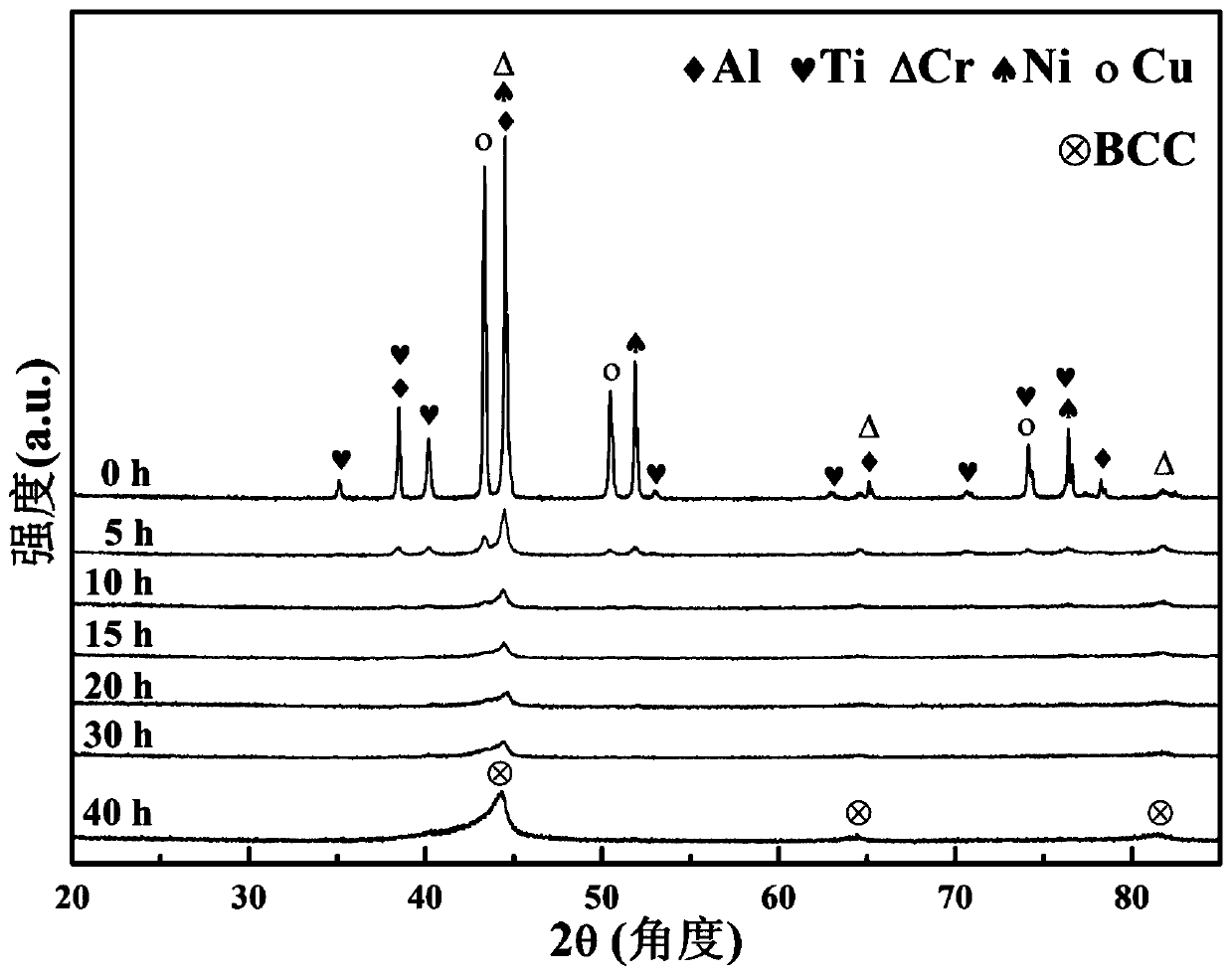

[0041] Step 2: Preparation of high-entropy alloy AlTiCrNiCu powder by mechanical alloying

[0042]Put the uniformly mixed powder in step 1 into a stainless steel ball mill tank, vacuumize and fill it with argon as a protective atmosphere, and carry out mechanical alloying on a planetary ball mill with a ball-to-material ratio of 10:1 and a rotational speed of 200r / min. The ball milling process ...

Embodiment 2

[0048] Step 1: Composition Design of High Entropy Alloy

[0049] Al designed 2 Ti 2 CrNiCu high-entropy alloy with a theoretical density of 5.63 / cm 3 , according to the high-entropy alloy Al 2 Ti 2 The molar atomic ratio of the main elements in CrNiCu is 2:2:1:1:1, and the mass of each component is calculated as Al powder 66.63g, Ti powder 118.22g, Cr powder 64.21g, Ni powder 72.47g, Cu powder 78.47g g. Weigh the corresponding mass with an electronic balance, put the powder into a container, and pass through argon protection, and then mix the powder on a V-type mixer for 36 hours until uniform.

[0050] Step 2: Preparation of high-entropy alloy Al by mechanical alloying 2 Ti 2 CrNiCu powder

[0051] Put the uniformly mixed powder in step 1 into a stainless steel ball mill tank, vacuumize and fill it with argon as a protective atmosphere, and perform mechanical alloying on a planetary ball mill with a ball-to-material ratio of 9:1 and a speed of 300r / min. The ball milli...

Embodiment 3

[0056] Step 1: Composition Design of High Entropy Alloy

[0057] AlTi 3 CrNiCu high-entropy alloy with a theoretical density of 5.88g / cm 3 , according to the high-entropy alloy AlTi 3 The molar atomic ratio of the main elements in CrNiCu is 1:3:1:1:1, and the mass of each component is calculated as Al powder 31.30g, Ti powder 166.59g, Cr powder 60.32g, Ni powder 68.08g, Cu powder 73.72 g. Weigh the corresponding mass with an electronic balance, put the powder into a container, and pass through argon protection, and then mix the powder on a V-type mixer for 24 hours until uniform.

[0058] Step 2: Preparation of high-entropy alloy AlTi by mechanical alloying 3 CrNiCu powder

[0059] Put the uniformly mixed powder in step 1 into a stainless steel ball mill tank, vacuumize it and fill it with argon as a protective atmosphere, and perform mechanical alloying on a planetary ball mill with a ball-to-material ratio of 9:1 and a speed of 350r / min. The ball milling process is carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com