Processing method for dendrobium devonianum paxt jelly and product thereof

A technology of Dendrobium purpurea and a processing method, applied in the direction of food science and the like, can solve the problem of not adding Dendrobium purpurea and the like, and achieve the effects of large market promotion value, reduction of nutrients, and improvement of utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

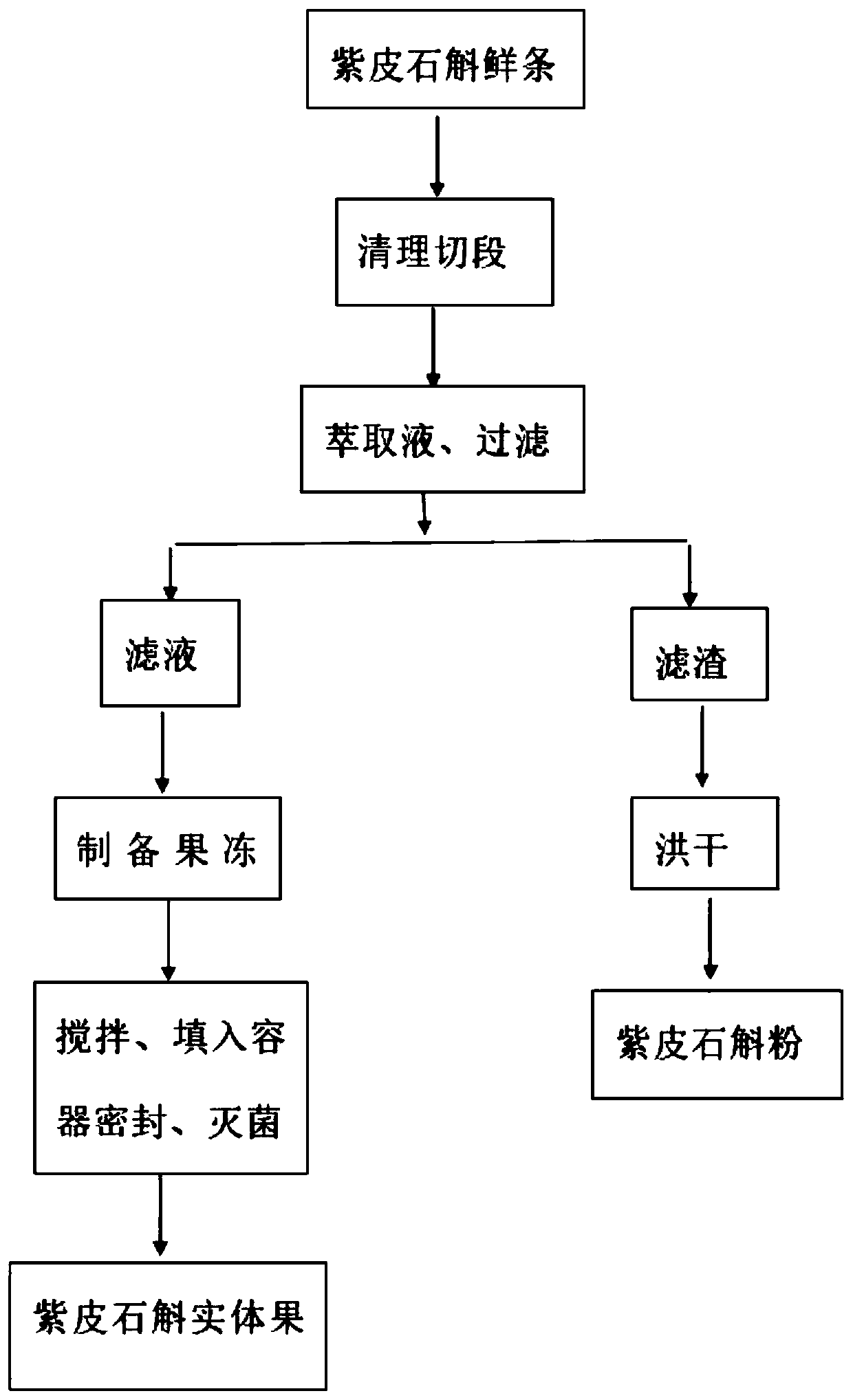

[0045] Such as figure 1 As shown, the present embodiment provides a kind of processing method of dendrobium jelly, comprising the following steps:

[0046] Step 1. Take the fresh strips of Dendrobium dendrobii, remove the leaf sheaths, wash them, cut them into sections and put them into a juice extractor. Dendrobium liquid; wherein, the weight ratio of Dendrobium dendrobii and water in step 1 juice extractor is 1:5-1:15;

[0047]Step 2, taking by weighing water, white granulated sugar, ginseng (artificially planted), compound glue, citric acid, dendrobium dendrobium liquid, preservative and maltose as raw materials, the parts by weight of each component in the raw material are respectively: water 50 parts, white 2 parts of granulated sugar, 2 parts of ginseng (artificially planted), 1.76 parts of compound glue, 0.1 part of citric acid, 60 parts of Dendrobium purple skin liquid, 0.03 parts of preservative, 2 parts of maltose; the ginseng used can be artificially planted;

[0...

Embodiment 2

[0052] The present embodiment provides a kind of processing method of dendrobium jelly, comprising the following steps:

[0053] Step 1, take the fresh strips of Dendrobium nobile, remove the leaf sheath, wash and cut into sections into the extraction machine, each section is 40mm in length, add water to the extraction machine, filter after extraction, collect the filtrate, and obtain the Dendrobium nodrobium liquid; Wherein, the weight ratio of dendrobium dendrobii and water in the step 1 extraction machine is 1:5-1:15, and the extraction speed of the extraction machine is 20-30rpm;

[0054] Step 2, taking water, white granulated sugar, ginseng (artificially planted), composite glue, citric acid, dendrobium dendrobium liquid, preservatives and maltose as raw materials, the parts by weight of each component are respectively: 50 parts of water, 3 parts of white granulated sugar 0.2 parts of ginseng (artificially planted), 0.88 parts of compound glue, 0.1 part of citric acid, 60...

Embodiment 3

[0059] On the basis of adopting the technical scheme of embodiment 1 or 2, the parts by weight of each component in the raw material are respectively: 60 parts of water, 15 parts of white granulated sugar, 0.5 part of ginseng (artificially planted), 1.84 parts of compound glue, 0.3 part of citric acid 80 parts, 80 parts of Dendrobium purple skin liquid, 0.05 parts of preservatives, 5 parts of maltose; The ginseng used can be selected artificially planted; The compound gum includes carrageenan, konjac gum, xanthan gum and locust bean gum, and each component The parts by weight are respectively 0.8 part of carrageenan, 0.8 part of konjac gum, 0.12 part of xanthan gum and 0.12 part of locust bean gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com