Preparation method of iron-silicon-aluminum alloy powder with high magnetic conductivity

A technology for the preparation of sendust and powder, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc. It can solve the problems of serious component segregation, easy growth of grains, and high energy consumption of multi-stage crushing. Achieve the effect of simple production process, improve purity and reduce oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

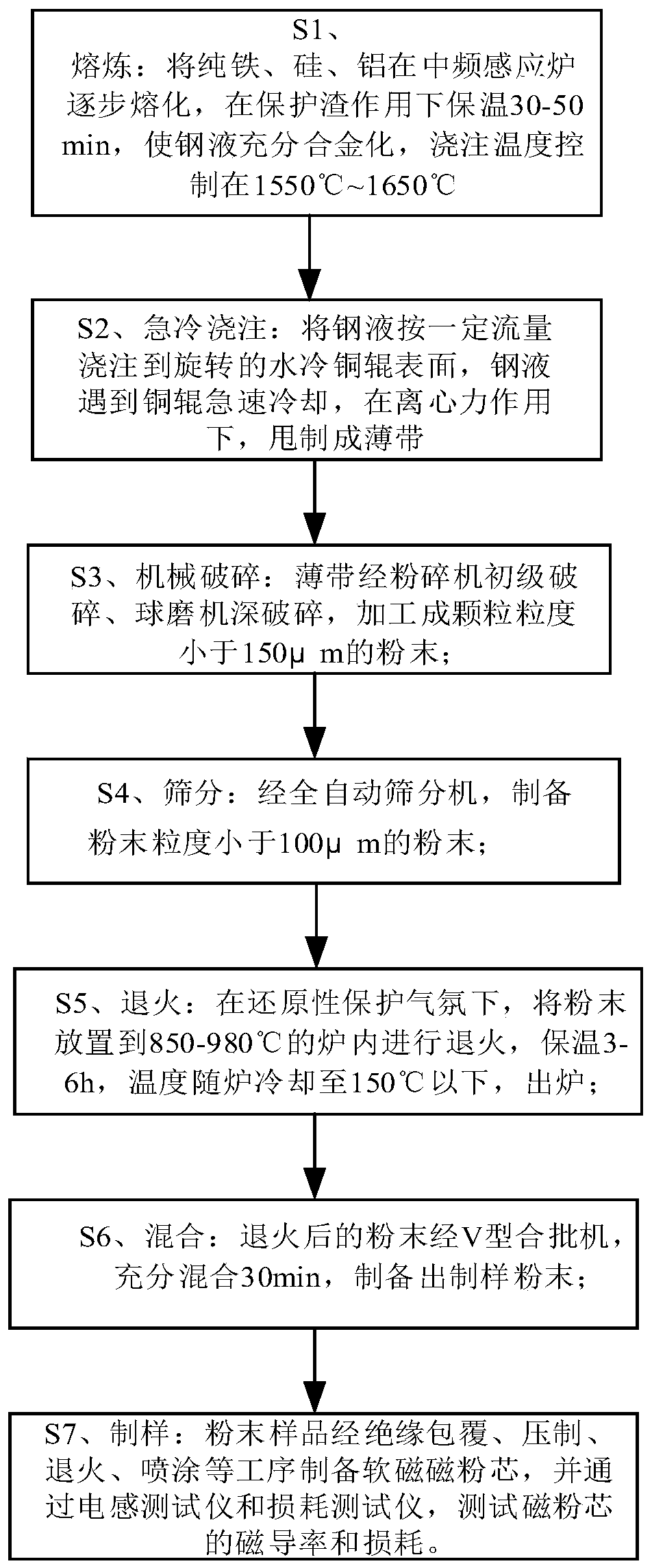

[0029] The present invention provides a kind of high magnetic permeability sendust aluminum alloy powder preparation method, such as figure 1 shown, including the following steps:

[0030] S1. Melting: Melt pure iron, silicon, and aluminum gradually in an intermediate frequency induction furnace, and keep them warm for 30-50 minutes under the action of alkaline reducing mold slag to fully alloy the molten steel. The pouring temperature is controlled at 1550°C to 1650°C;

[0031] S2. Quenching pouring: The entire copper roller is processed in a closed container, filled with nitrogen protection, and the molten steel is poured on the surface of the water-cooled copper roller with a rotation speed of 40-50r / min at a flow rate of 20Kg-40Kg / min. Cooling, and the solidification cooling rate of the molten steel is as high as 500°C / s. Under the action of centrifugal force, it is thrown into thin strips. The inside of the copper roller adopts a circulating waterway, and the water inlet ...

Embodiment 1

[0038] Use medium frequency induction melting furnace to smelt FeSiAl powder, the composition is: Si: 9.6%, Al: 5.4%, the balance is Fe; add iron, silicon, aluminum alloy to the induction furnace in turn, and stir evenly after all the metals are melted; Add composite mold slag, keep it warm for 30 minutes, increase the power of the intermediate frequency induction furnace, and pour molten steel when the temperature of the molten steel reaches 1550°C;

[0039] The molten steel is poured onto the surface of the rotating water-cooled copper roller. The pouring speed of the molten steel is 25Kg / min, and the rotation speed of the water-cooled copper roller is 40r / min. Under the action of rapid cooling and the centrifugal force of the copper roller, the molten steel is quickly made into a thin strip ;

[0040] The sendust aluminum strip is crushed by a pulverizer and processed into powder particles of about 5mm; the crushed metal particles are added to a horizontal ball mill for fur...

Embodiment 2

[0046] Use medium frequency induction melting furnace to smelt FeSiAl powder, the composition is: Si: 9.6%, Al: 5.4%, the balance is Fe; add iron, silicon, aluminum alloy to the induction furnace in turn, and stir evenly after all the metals are melted; Add composite mold slag, keep it warm for 40 minutes, increase the power of the intermediate frequency induction furnace, and pour molten steel when the temperature of the molten steel reaches 1600°C;

[0047] The molten steel is poured onto the surface of the rotating water-cooled copper roller. The pouring speed of the molten steel is 35Kg / min, and the rotation speed of the water-cooled copper roller is 45r / min. Under the action of rapid cooling and the centrifugal force of the copper roller, the molten steel is quickly made into a thin strip ;

[0048] The sendust aluminum strip is crushed by a pulverizer and processed into powder particles of about 5mm; the crushed metal particles are added to a horizontal ball mill for fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com