Cast steel added with rare earth elements

A rare earth element, cast steel technology, applied in the improvement of process efficiency, furnace type, furnace and other directions, can solve problems such as insufficient toughness, and achieve the effects of improving lasting strength, increasing yield strength, and refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing cast steel added with rare earth elements, comprising the following steps:

[0038] Step 1, weighing 0.12 parts of La, 0.36 parts of Ce and 0.12 parts of Y and placing them in a ball mill for mechanical ball milling under the protection of argon to obtain nanometer rare earth elements RE;

[0039] Step 2, weigh 45 parts of pig iron and 20 parts of scrap steel and put them into an electric furnace to melt, add 3 parts of ferrosilicon, 1.8 parts of ferromanganese, 12 parts of ferrochrome, 1.2 parts of ferromolybdenum, and 1.6 parts of ferrovanadium, desulfurize after melting, so that S≤ 0.005%; dephosphorization, so that P≤0.005%; slag removal, to obtain mixed molten steel;

[0040] Step 3, inject the mixed molten steel into the AOD furnace through the ladle, blow oxygen and decarburize, and make the carbon content meet the process requirements;

[0041] Step 4, transfer the molten steel after decarburization in step 3 into a refining furnace, dete...

Embodiment 2

[0053] A method for preparing cast steel added with rare earth elements, comprising the following steps:

[0054] Step 1, weighing 0.04 parts of La, 0.12 parts of Ce and 0.04 parts of Y and placing them in a ball mill under the protection of argon for mechanical ball milling to obtain nanometer rare earth elements RE;

[0055] Step 2, weigh 40 parts of pig iron and 15 parts of scrap steel and put them into an electric furnace to melt, add 2.5 parts of ferrosilicon, 1.2 parts of ferromanganese, 7 parts of ferrochrome, 0.2 parts of ferromolybdenum, and 1.1 parts of ferrovanadium, desulfurize after melting, so that S≤ 0.005%; dephosphorization, so that P≤0.005%; slag removal, to obtain mixed molten steel;

[0056] Step 3, inject the mixed molten steel into the AOD furnace through the ladle, blow oxygen and decarburize, and make the carbon content meet the process requirements;

[0057] Step 4, transfer the molten steel after decarburization in step 3 into a refining furnace, det...

Embodiment 3

[0069] A raw material for cast steel added with rare earth elements, in parts by weight, consists of the following components:

[0070] 50 parts of pig iron, 25 parts of steel scrap, 4.5 parts of ferrosilicon, 2.4 parts of ferromanganese, 15 parts of ferrochromium, 2 parts of ferromolybdenum, 2.1 parts of ferrovanadium, 0.05 parts of aluminum particles, 0.16 parts of rare earth element La, 0.48 part of rare earth element Ce, Rare earth element Y 0.16 part;

[0071] The preparation method of the above-mentioned cast steel added with rare earth elements comprises the following steps:

[0072] Step 1, weighing 0.16 parts of La, 0.48 parts of Ce and 0.16 parts of Y and placing them in a ball mill for mechanical ball milling under the protection of argon to obtain nanometer rare earth elements RE;

[0073] Step 2, weigh 50 parts of pig iron and 25 parts of scrap steel and put them into an electric furnace to melt, add 4.5 parts of ferrosilicon, 2.4 parts of ferromanganese, 15 part...

PUM

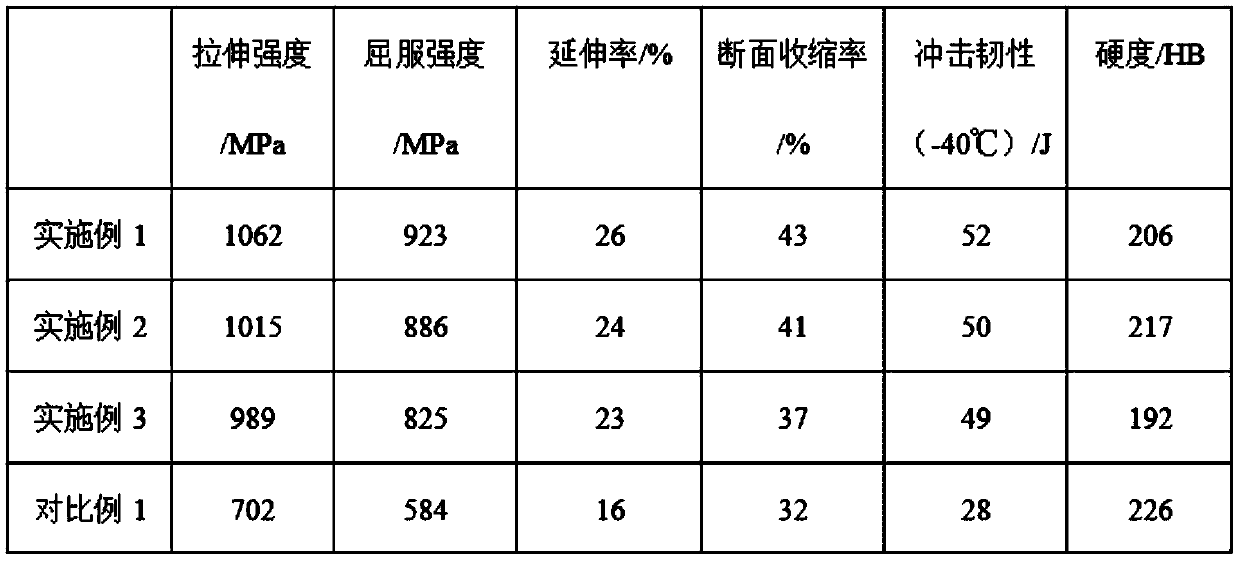

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com